Preparation method of high-performance isononanoic acid

A high-performance technology of isononanoic acid, applied in the field of preparation of high-performance isononanoic acid, can solve the problems of accelerated decomposition of peroxides, difficult separation of metal ions, and enrichment of peroxides, so as to promote the initiation and production risks. The effect of reducing and increasing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

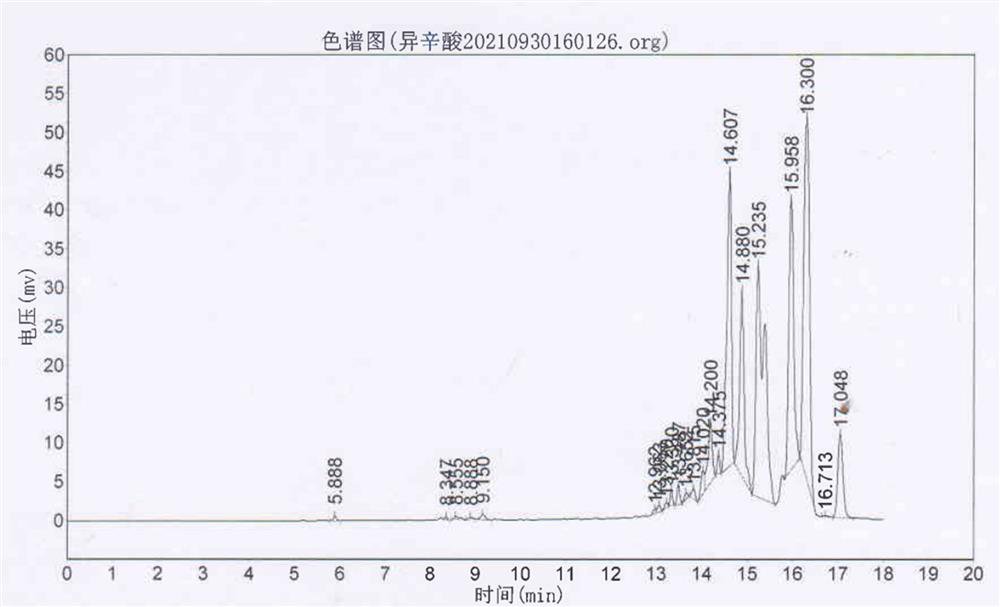

Image

Examples

Embodiment 1

[0037] A kind of preparation method of isononanoic acid, is characterized in that, comprises the steps:

[0038] Step 1: Synthesis of isononanoic acid: Mix 900 g of isonononanol, 240 g of sodium hydroxide, and 10 g of zinc oxide catalyst uniformly, add it into a reaction vessel, heat up to 260° C. under stirring, and react for 2 hours at a stirring speed of 200 r / min. During the reaction, the pressure of the reactor was increased, and the pressure of 2MPa was maintained for 3h, then the pressure was released, and the temperature was cooled to normal temperature to obtain the crude product of the sodium salt of isononanoic acid;

[0039] Step 2: Dilution of the crude sodium salt of isononanoic acid: adding the crude sodium salt of isononanoic acid to an equal amount of deionized water, the reaction vessel is heated to 90° C., and is stirred and diluted to obtain a dilution of the crude sodium salt of isononanoic acid ;

[0040] Step 3: Acidification treatment: acidify the crud...

Embodiment 2

[0046]A kind of preparation method of isononanoic acid, is characterized in that, comprises the steps:

[0047] Step 1: Synthesis of isononanoic acid: Mix 900 g of isonononanol, 240 g of sodium hydroxide, and 10 g of zinc oxide catalyst uniformly, add it into the reaction vessel, heat up to 260 ° C under stirring, and react for 3 hours, and the stirring speed is 200 r / min, During the reaction, the pressure of the reactor was raised, and the pressure was kept at 3MPa for 2h, then the pressure was released, and the temperature was cooled to room temperature to obtain the crude product of the sodium salt of isononanoic acid;

[0048] Step 2: dilution of the crude sodium salt of isononanoic acid: adding the crude sodium salt of isononanoic acid to an equal amount of deionized water, the reaction vessel is heated to 95° C., stirred and diluted to obtain the dilution of the crude sodium salt of isononanoic acid ;

[0049] Step 3: Acidification treatment: acidify the crude sodium sa...

Embodiment 3

[0055] A kind of preparation method of isononanoic acid, is characterized in that, comprises the steps:

[0056] Step 1: Synthesis of isononanoic acid: Mix 1000 g of isonononanol, 260 g of sodium hydroxide, and 12 g of zinc oxide catalyst uniformly, add it into a reaction vessel, heat up to 280° C. under stirring, and react for 3 hours at a stirring speed of 250 r / min. During the reaction, the pressure of the reactor was raised, and the pressure of 4MPa was maintained for 2h, then the pressure was released, and the temperature was cooled to room temperature to obtain the crude product of the sodium salt of isononanoic acid;

[0057] Step 2: dilution of the crude sodium salt of isononanoic acid: adding the crude sodium salt of isononanoic acid to an equal amount of deionized water, the reaction vessel is heated to 95° C., stirred and diluted to obtain the dilution of the crude sodium salt of isononanoic acid ;

[0058] Step 3: Acidification treatment: acidify the crude sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com