Protein nanostructure as well as self-assembly method and application thereof

A nanostructure and self-assembly technology, applied in the field of nanomaterials, can solve the problems of high reaction temperature, insoluble in water, and inapplicability of bio-based materials, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

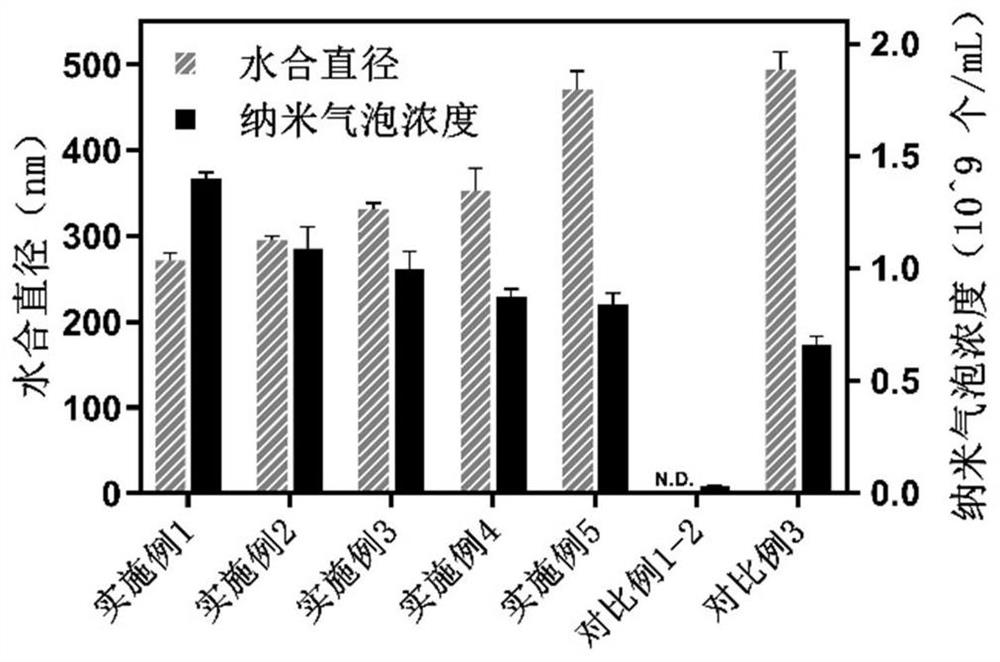

[0042] An aspect of the embodiments of the present invention provides a method for preparing a self-assembled core-shell structural protein nanoparticle and a hollow structural protein nanofiber, including:

[0043] Prepare bulk nanobubbles, and uniformly mix the solution containing bulk nanobubbles with protein;

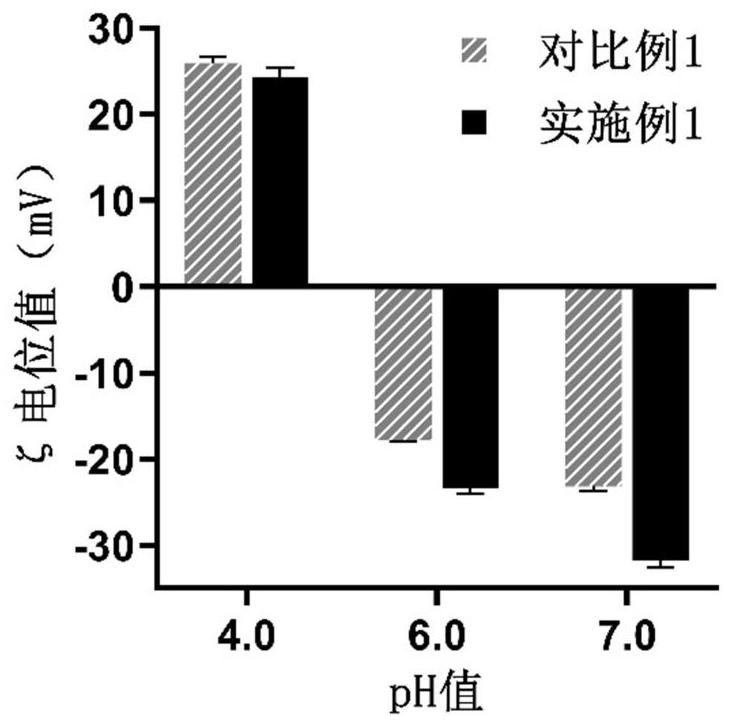

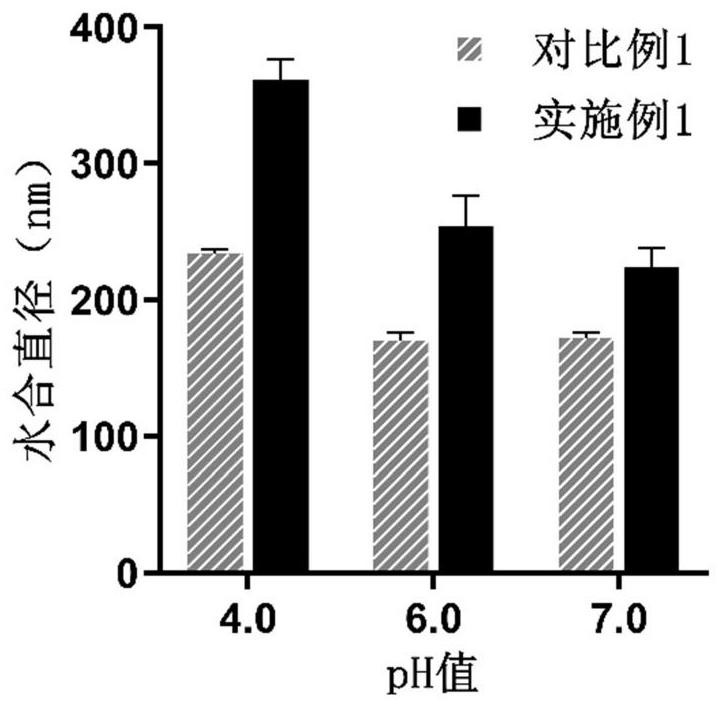

[0044] Adjust the pH value, protein concentration and bulk nanobubble concentration of the reaction system, change the hydrophobic interaction and electrostatic interaction strength between the protein and bulk nanobubble, and make the protein stably adsorbed in the gas of bulk nanobubble. - At the liquid interface, self-assembled core-shell structural protein nanoparticles are formed;

[0045] Heating the obtained mixture for a short time to partially denature the protein to form stable self-assembled nucleocapsid protein nanoparticles;

[0046] Elevating the reaction temperature and prolonging the heating time completely denatures the protein and forms self-assem...

Embodiment 1

[0092] (1) Put ultrapure water with a conductivity of 18.2 MΩ·cm in a closed container, and pass pure air into the ultrapure water at a flow rate of 350 mL / min for 10 min to make the pure air content in the water. reach saturation.

[0093] (2) Reduce the pressure of the airtight container to 5.0 kPa, and then gradually pressurize to restore the pressure inside the container to atmospheric pressure. After repeated decompression and pressure mixing, bulk nanobubbles are formed in the solution.

[0094] (3) Mix pea protein isolate and ultrapure water thoroughly, and continue stirring at 500 rpm for 2 h at 25 °C to prepare a solution with a protein concentration of 1.2 mg / mL, and then stand at 4 °C for 24 h to make pea protein isolate. Fully hydrated, then centrifuged at 4 °C and 8000 rpm for 20 min to collect the soluble pea protein isolate solution.

[0095] (4) Add the bulk nanobubble aqueous solution in step (2) dropwise to the pea protein isolate solution obtained in step (...

Embodiment 2

[0101] (1) Put ultrapure water with a conductivity of 18.2 MΩ·cm in a closed container, and pass pure air into the ultrapure water at a flow rate of 200 mL / min and keep it for 20 min to make the pure air content in the water. reach saturation.

[0102] (2) Reduce the pressure of the airtight container to 4.0 kPa, and then gradually pressurize to restore the pressure inside the container to atmospheric pressure. After repeated decompression and pressure mixing, bulk nanobubbles are formed in the solution.

[0103] (3) Mix pea protein isolate and ultrapure water thoroughly, and continue stirring at 500 rpm for 2 h at 20 °C to prepare a solution with a protein concentration of 3.0 mg / mL, and then stand at 8 °C for 36 h to make pea protein isolate. Fully hydrated, then centrifuged at 4 °C and 4000 rpm for 40 min to collect the soluble pea protein isolate solution.

[0104] (4) Add the bulk nanobubble aqueous solution in step (2) dropwise to the pea protein isolate solution obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com