Flexible solar cell chip and preparation method and application thereof

A flexible solar cell and chip technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as easy breakage, battery array failure, and reduced production yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] This embodiment is a flexible solar cell chip and a preparation method thereof.

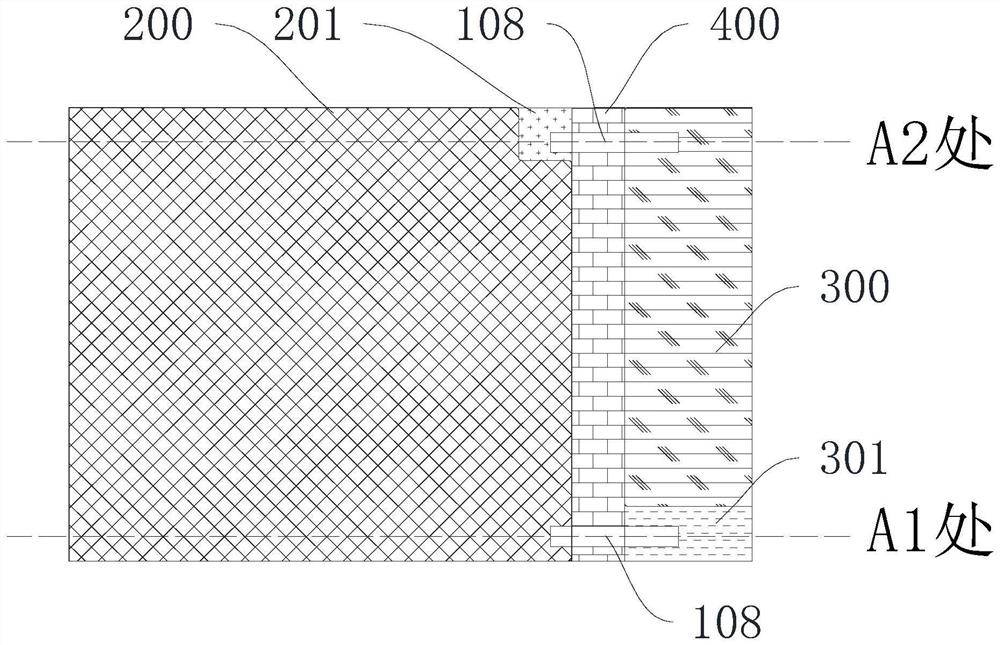

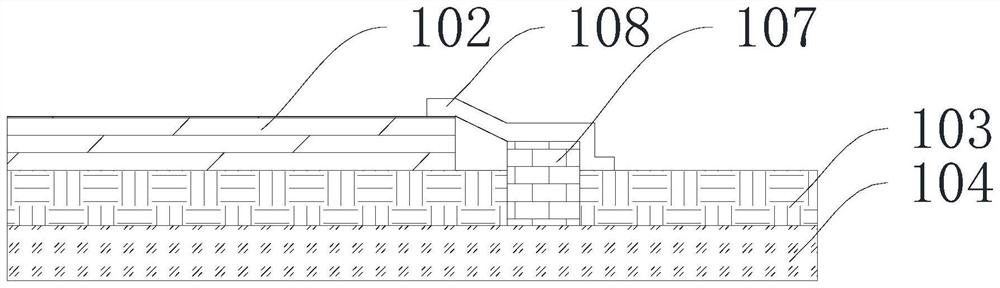

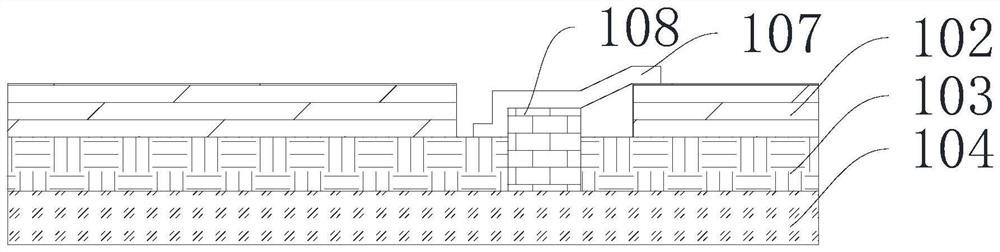

[0169] Top view of the flexible solar cell chip in this embodiment figure 1 , consists of a solar cell epitaxial region 200, a solar cell lower electrode region 201, a diode epitaxial region 300, a diode lower electrode region 301 and an isolation region 400;

[0170] The lower electrode region 201 of the solar cell is electrically connected to the diode epitaxial region 300 through the first interconnecting electrode;

[0171] The solar cell epitaxial region 200 is electrically connected to the diode lower electrode region 301 through the second interconnection electrode;

[0172] The isolation region 400 is used to separate the solar cell epitaxial region 200 and the diode epitaxial region 300 .

[0173] The solar cell epitaxial region 200 is formed by stacking the following film layers in sequence:

[0174] PI layer 104, first metal bonding layer, P-type GaInAs ohmic contact layer 10...

Embodiment 2

[0230] This embodiment is a flexible solar cell chip and a preparation method thereof.

[0231] The difference between the flexible solar cell chip in this embodiment and Embodiment 1 is:

[0232] The pyrolysis film in Example 1 was replaced with UV glue (NBD-5172K from Nitto).

[0233] The UV glue removal method is as follows: removing the bonding between the organic bonding layer 105 and the PI layer 104 under UV irradiation for 3 minutes.

Embodiment 3

[0235] This embodiment is a flexible solar cell chip and a preparation method thereof.

[0236] The difference between the flexible solar cell chip in this embodiment and Embodiment 1 is:

[0237] The silicon wafer in Example 1 was replaced with a glass wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com