MXene-coated ternary positive electrode material, preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as complex material preparation procedures, achieve complex preparation procedures, improve electronic conductance and ion conductivity, Effects of Improving Rate Performance and Cycle Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

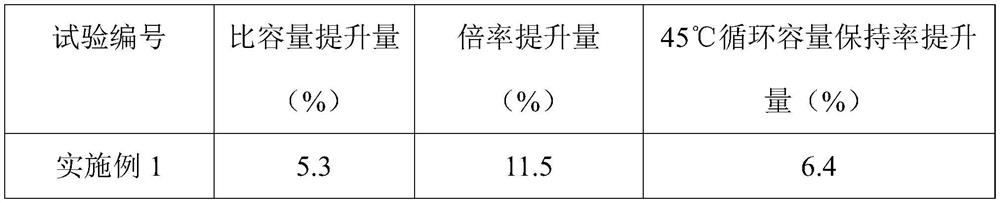

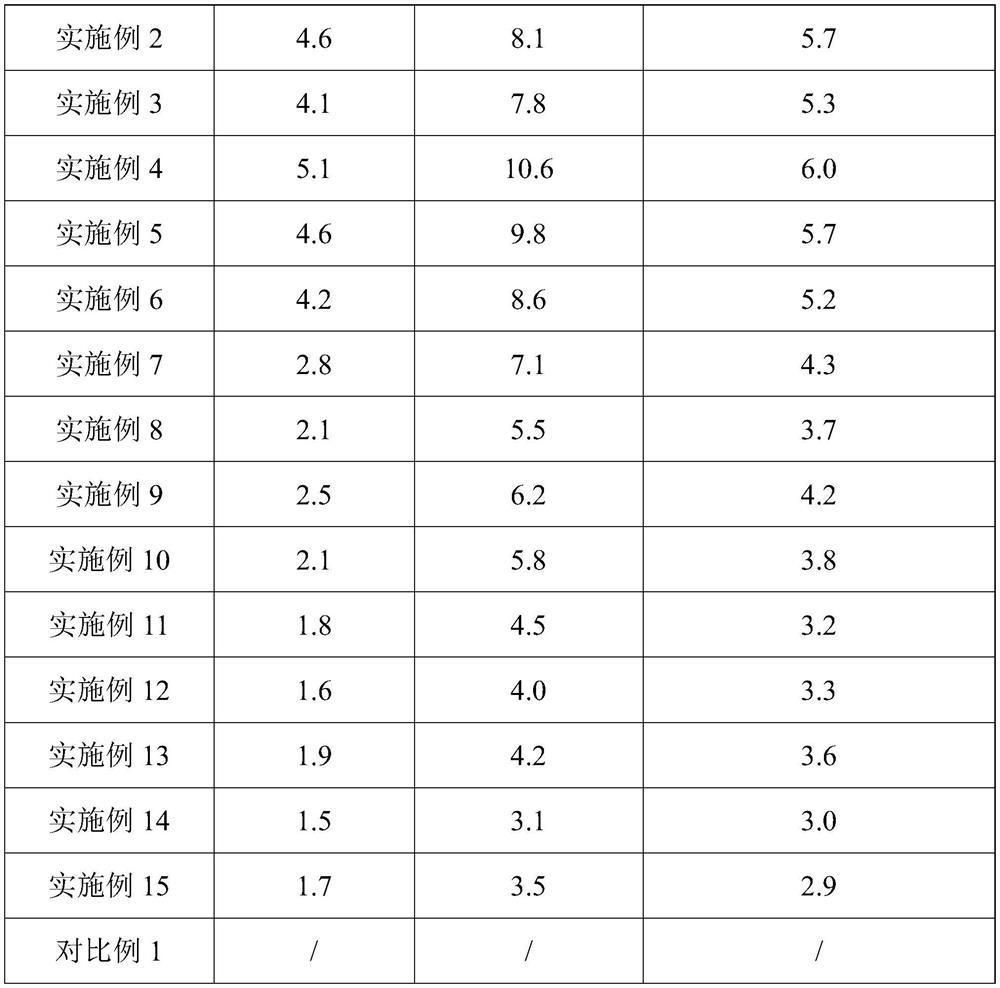

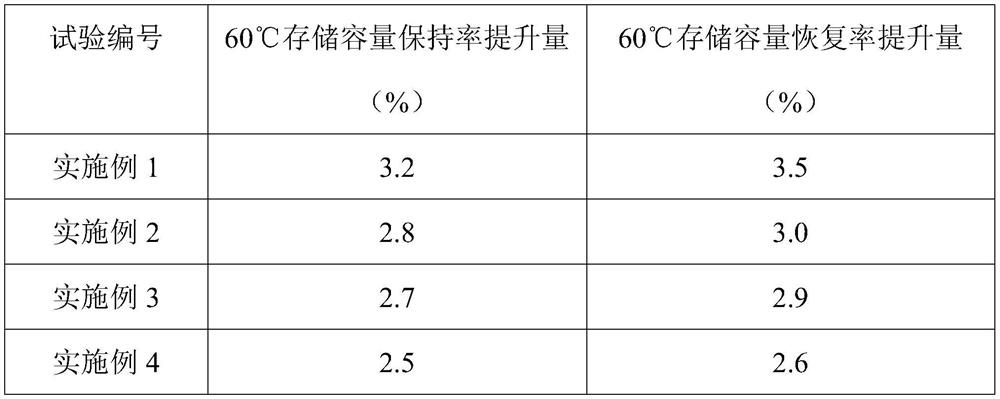

Examples

Embodiment 1

[0051] This embodiment provides a preparation method of MXene-coated ternary positive electrode material, and the preparation method includes the following steps:

[0052] (1) Mixed Ti 3 AlC 2 and LiF / HCl mixed solution, wherein the mass fraction of HCl is 20wt%, the concentration of LiF is 2.5mol / L, and the reaction is stirred for 2.5h to obtain Ti 3 C 2 ;

[0053] (2) Mixed NCM811 (chemical formula is Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 ) precursor and lithium hydroxide, calcined at 850 °C for 12 h in an oxygen atmosphere to obtain a ternary cathode first-fired product;

[0054] (3) mixed water, step (1) gained Ti 3 C 2 and step (2) obtained ternary cathode first calcined product, the mass ratio of MXene and ternary cathode first calcined product is 1:100, the liquid-solid ratio after mixing is 250mL / g, and the secondary calcination temperature is 500 ℃ for 8h, The MXene-coated ternary cathode material is obtained.

Embodiment 2

[0056] This embodiment provides a preparation method of MXene-coated ternary positive electrode material, and the preparation method includes the following steps:

[0057] (1) Mixed Ta 4 GaC 3 and LiF / HCl mixed solution, wherein the mass fraction of HCl is 25wt%, the concentration of LiF is 5mol / L, and the reaction is stirred for 0.5h to obtain Ta 4 C 3 ;

[0058] (2) Mixing NCM811 precursor and lithium carbonate, and calcining at 900 °C for 15 hours in an air atmosphere to obtain a ternary cathode first-fired product;

[0059] (3) Mix NMP, the Ta obtained in step (1) 4 C 3 and the ternary cathode first calcined product obtained in step (2), the mass ratio of MXene and the ternary cathode first calcined product is 1:5, the liquid-solid ratio after mixing is 100 mL / g, and the secondary calcination at 150 ° C is carried out in an oxygen atmosphere. After calcination for 13h, the MXene-coated ternary cathode material was obtained.

Embodiment 3

[0061] This embodiment provides a preparation method of MXene-coated ternary positive electrode material, and the preparation method includes the following steps:

[0062] (1) Hybrid (V 0.5 Cr 0.5 ) 3 AlC 2 and LiF / HCl mixed solution, wherein, the mass fraction of the HCl is 10wt%, the concentration of LiF is 2mol / L, and the reaction is stirred for 5h to obtain (V 0.5 Cr 0.5 ) 3 C 2 ;

[0063] (2) Mixing the NCM811 precursor and lithium carbonate, and calcining at a temperature of 1100 ° C for 7 hours to obtain a ternary cathode first-fired product;

[0064] (3) mixed water, step (1) gained (V 0.5 Cr 0.5 ) 3 C 2 With the ternary cathode first-fired product obtained in step (2), the mass ratio of MXene and the ternary cathode first-fired product is 1:200, the liquid-solid ratio after mixing is 500mL / g, and the temperature is 850 ℃ in an air atmosphere. Secondary calcination was performed for 2 h to obtain the MXene-coated ternary cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com