Process and apparatus for treating water by magneto-electric dialysis

A dialyzer and magnetoelectric technology, applied in the field of equipment for electrochemical treatment of water, can solve the problem of reducing membrane and electrode electrodialysis performance and service life, water treatment speed and treatment quality can no longer be improved, current efficiency can no longer be improved, etc. problems, to reduce the frequency of dismantling and washing or frequent pole reversal, improve water treatment capacity, improve use efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

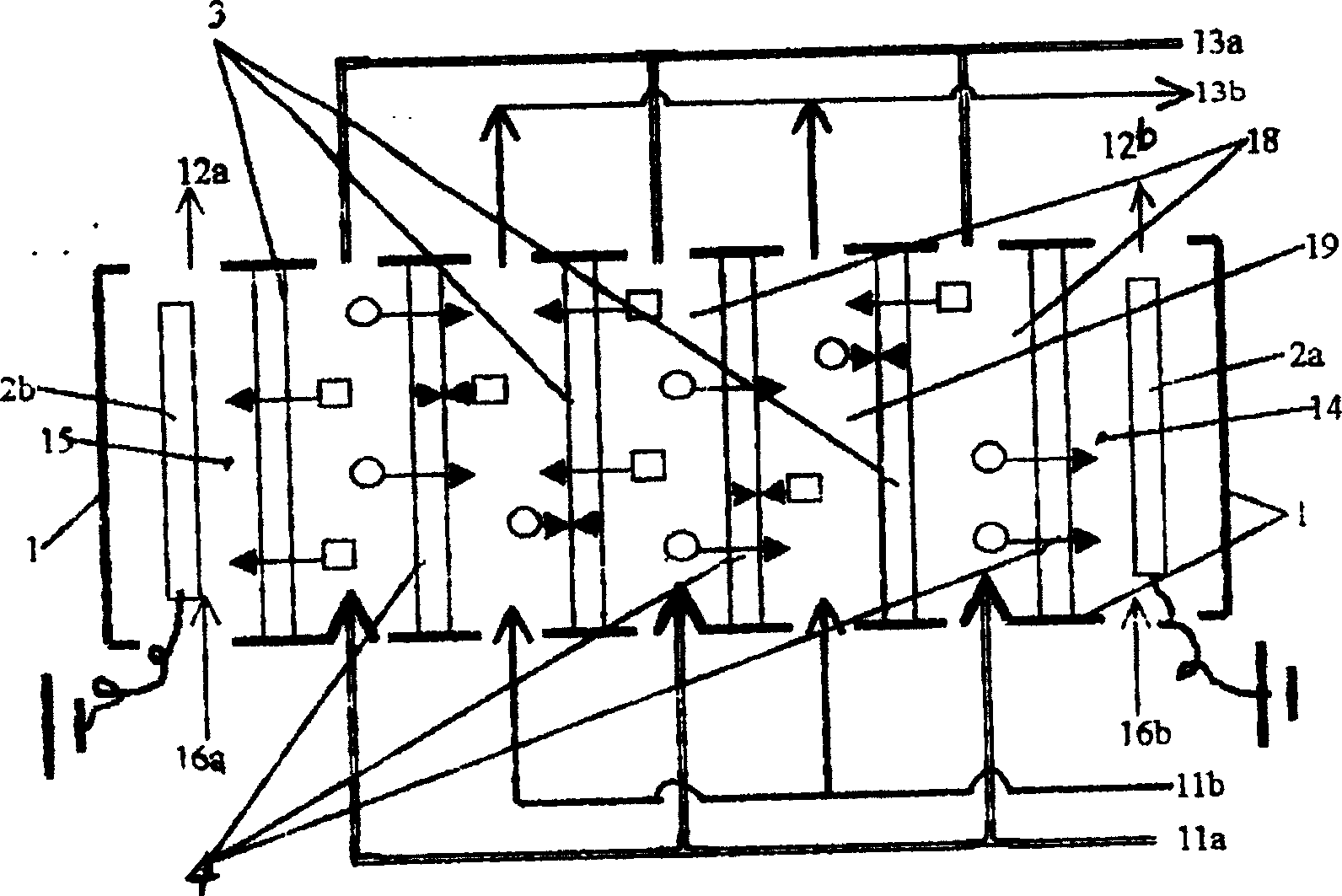

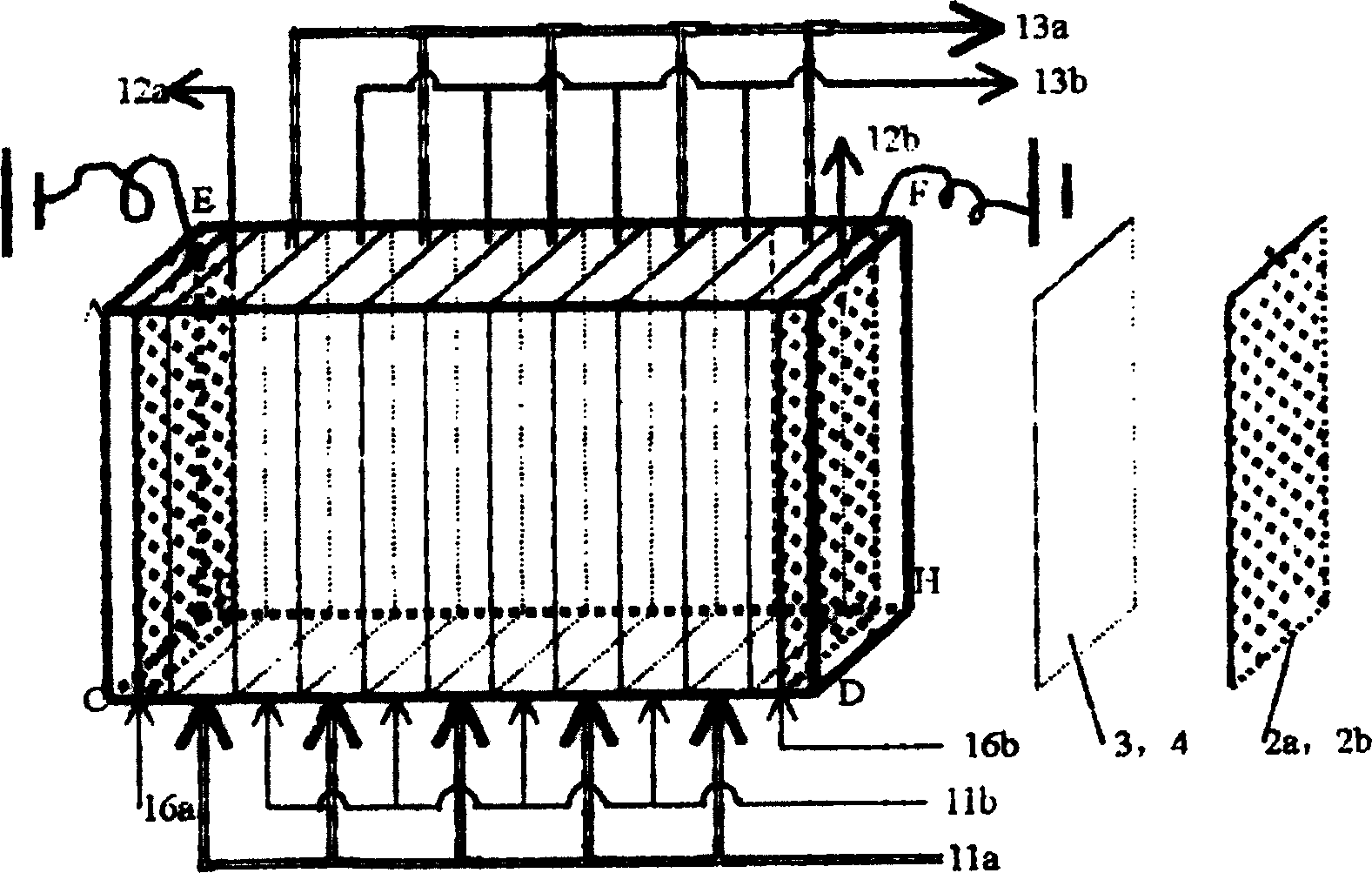

[0014] Embodiment 1. present embodiment magnetoelectric dialyzer, its structure can be from Figure 5 see, and its internal structure can refer to figure 1 and figure 2 . It contains a shell 1 with six shell walls up, down, left, right, front, back, and the upper and lower shell walls of the shell are provided with raw water inlets 11a and 11b (except that 11a and 11b must be separated when the poles are frequently reversed, the rest of the case Tubes 11a and 11b can be combined into one), electrode flushing water inlet 16 (wherein 16b is the anode flushing water inlet, 16a is the cathode flushing water inlet), electrode flushing water outlet 12 (12b is the anode flushing water outlet, if flowing out dilute Acid solution chlorine water; 12a is the cathode washing outlet, such as flowing out dilute lye (NaOH), desalinated water outlet 13a and concentrated water outlet 13b; there are anode chamber 14 and cathode chamber 15 in the housing, anode 2a is arranged in the anode ch...

Embodiment 2

[0016] Embodiment 2. The difference from Embodiment 1 is that the strength of the static magnetic field between the two permanent magnet plates 6 is not less than 0.5 Tesla. Because the Lorent magnetic force Fm=qvB is proportional to the magnetic field strength B, the greater the magnetic field strength is, the better the design offset force of the static magnetic field is to the ions, the better the effect is, and it is also beneficial to improve the water treatment speed. It would be more ideal if a superconductor strong magnetic field above 20 tesla could be used. In addition, since the Lorent magnetic force is a vector, the electrodialysis space of the magnetoelectric dialysis device of the present invention must be non-loop type, so that the liquid flow flows along the entire membrane surface, and the general direction of the flow velocity remains consistent.

Embodiment 3

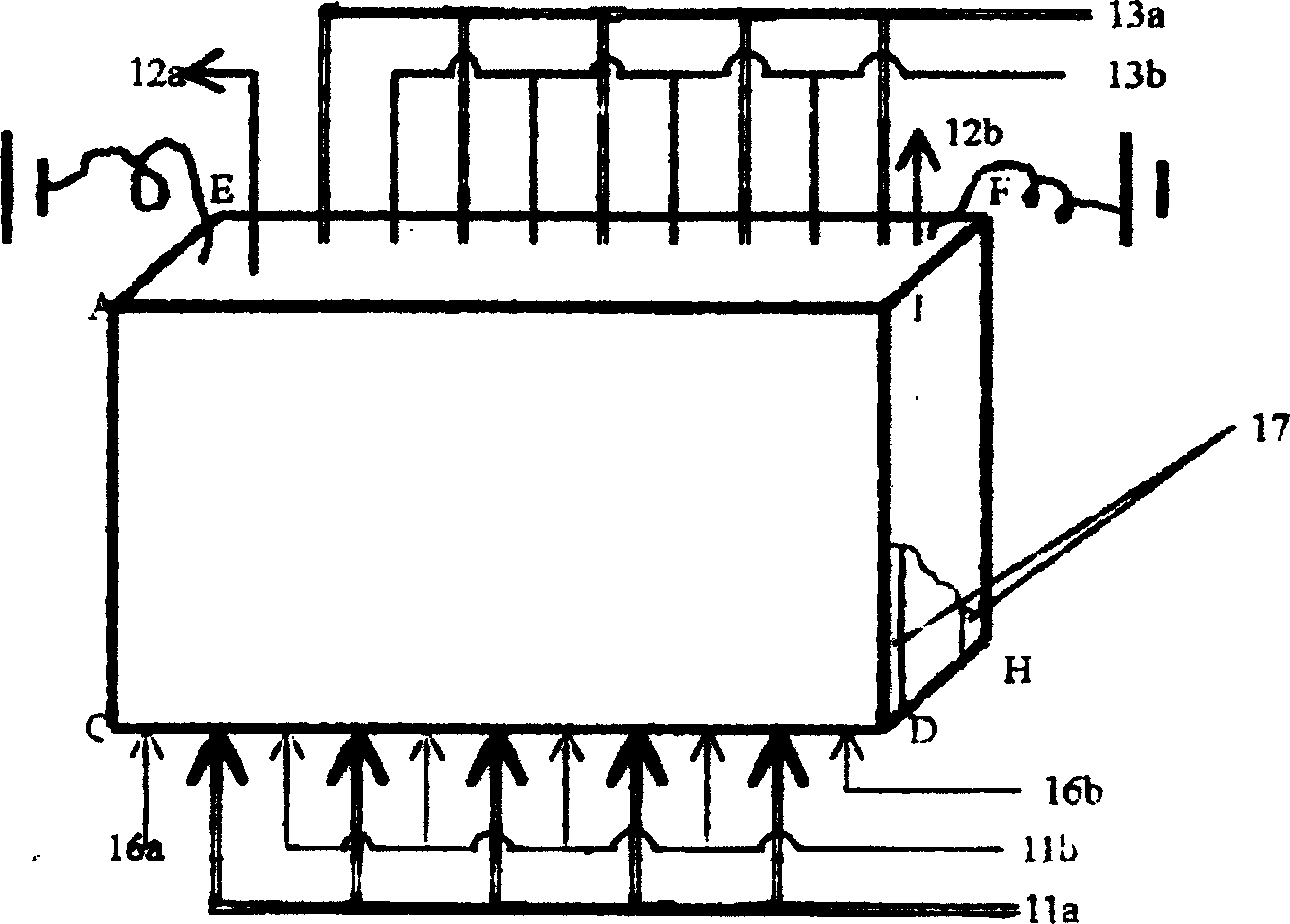

[0017] Example 3. Available from Figure 5 It can be seen from the figure that the difference from Embodiment 1 and Embodiment 2 is that the two shell walls of the shell parallel to the water flow and the current direction are high magnetic permeability material plates 17, and the rest of the shell walls are all magnetically permeable than before. Low magnetic permeability material plates with low shell walls. In order to overcome the magnetic field shielding effect of the remaining shell walls, the effect on the applied magnetic field is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com