Hydrogen bond receptor type spherical polymeric adsorbent and method for extracting puerarin

A technology for adsorbing resin and puerarin, applied in chemical instruments and methods, pharmaceutical formulations, other chemical processes, etc., can solve the problems of reduced adsorption selectivity, difficulty in obtaining high-purity puerarin products, etc., and achieve high selectivity and cost. Low, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

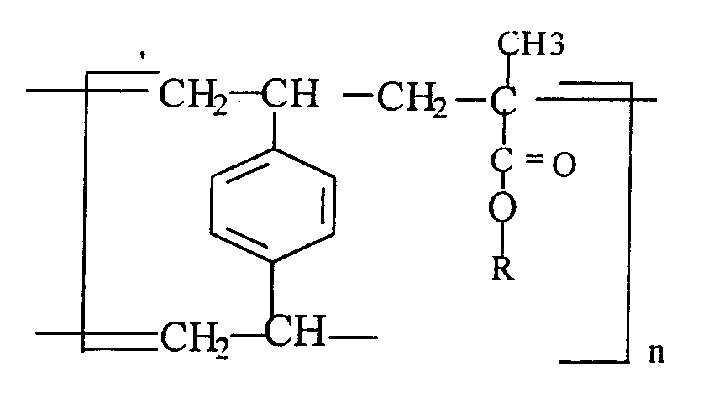

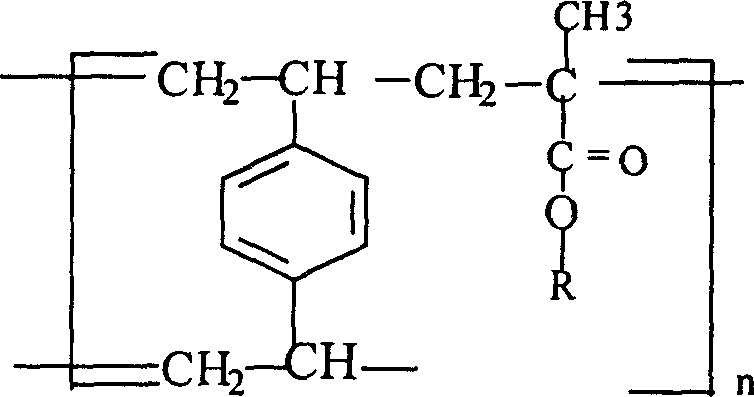

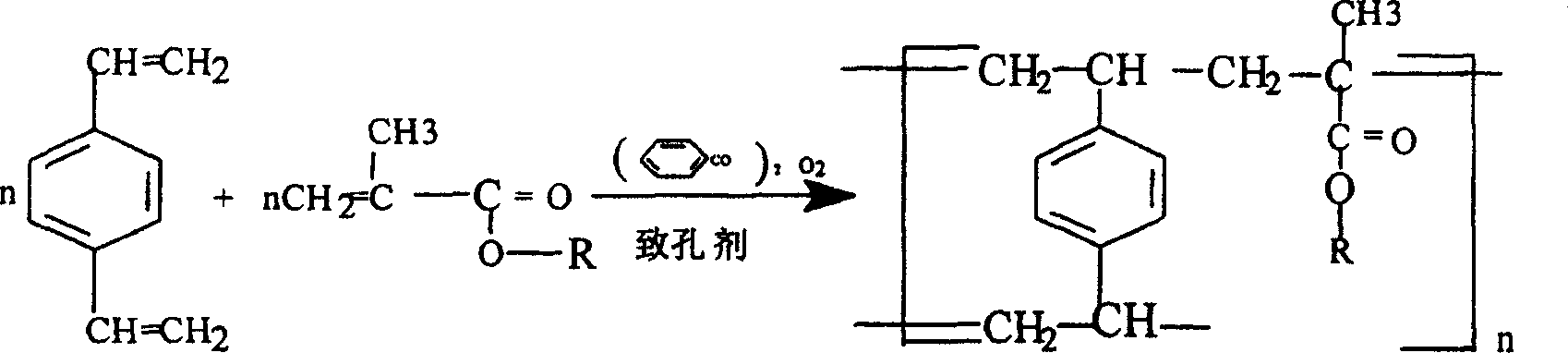

Method used

Image

Examples

Embodiment 1

[0014] Dissolve gelatin in water to make a 1% (w / w) aqueous solution. Stir and mix divinylbenzene: methyl acrylate: cyclohexanol = 1:1:1.5 and benzoyl peroxide (1% of the monomer amount), and the volume is equivalent to 1 / 4-1 of the water phase / 3), add it to the water phase, start stirring, raise the temperature (1°C / 2min) to 78-80°C, and keep it at this temperature for 3 hours after being finalized. Then the temperature was raised to 91-93° C., maintained for 5 hours, and then raised to 95° C., maintained for 4 hours. After the polymerization is completed, the material is discharged, fully washed with hot water, and a spherical hydrogen bond acceptor type adsorption resin with a particle size of 0.3-1 mm is prepared.

Embodiment 2

[0016] 20 grams of kudzu root (Guangxi Pueraria lobata) was pulverized, and 200 ml of 70% ethanol aqueous solution was used to reflux for 3 hours. After recovering the ethanol from the extract, it was diluted with water to 100-120 ml, and the clarified aqueous solution was filtered. The aqueous solution obtained is passed into the resin post (column diameter 15mm, 30ml resin is housed) of the spherical hydrogen bond acceptor type adsorption resin that is prepared in embodiment 1, and puerarin will be effectively adsorbed in the resin, and then After washing with 50-100 ml of deionized water and desorbing with 100 ml of 50% ethanol, the flow rate of adsorption, washing and desorption is 0.5 times of bed volume / hour. The desorbed solution is concentrated under reduced pressure, dried in vacuum and pulverized to obtain powdery puerarin extract. After high performance liquid chromatography analysis, the content of puerarin is more than 80%, and the yield is 1.0%.

Embodiment 3

[0018] Crush 20 kg of Pueraria lobata (Guangxi Pueraria lobata) and reflux with ethanol aqueous solution. After recovering ethanol from the extract, add water to dilute to 100-120 liters, and filter to obtain a clear aqueous solution. The aqueous solution that obtains is passed into the resin post (column diameter 80mm, 40 liters of resin is housed) of the spherical hydrogen bond acceptor type adsorption resin that is prepared in embodiment 1, and puerarin will be effectively adsorbed in the resin, After washing with 50-100 liters of deionized water, desorb with 150 liters of 50% ethanol, the flow rate of adsorption, washing and desorption is 0.5 times of bed volume / hour. The desorbed solution is concentrated under reduced pressure, dried in vacuum and pulverized to obtain powdered puerarin extract. According to high performance liquid chromatography analysis, the content of puerarin is more than 63%, and the yield is about 1.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com