Thiobacillus thiooxidans and biological eliminating method of chromium in tanning sludge

A technology of Thiobacillus thiooxidans and tannery sludge, which is applied in the field of environmental engineering, can solve the problems of harsh operating environment, secondary pollution, and high cost of chemical extraction, and achieves friendly operating environment, mild reaction, and no secondary pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

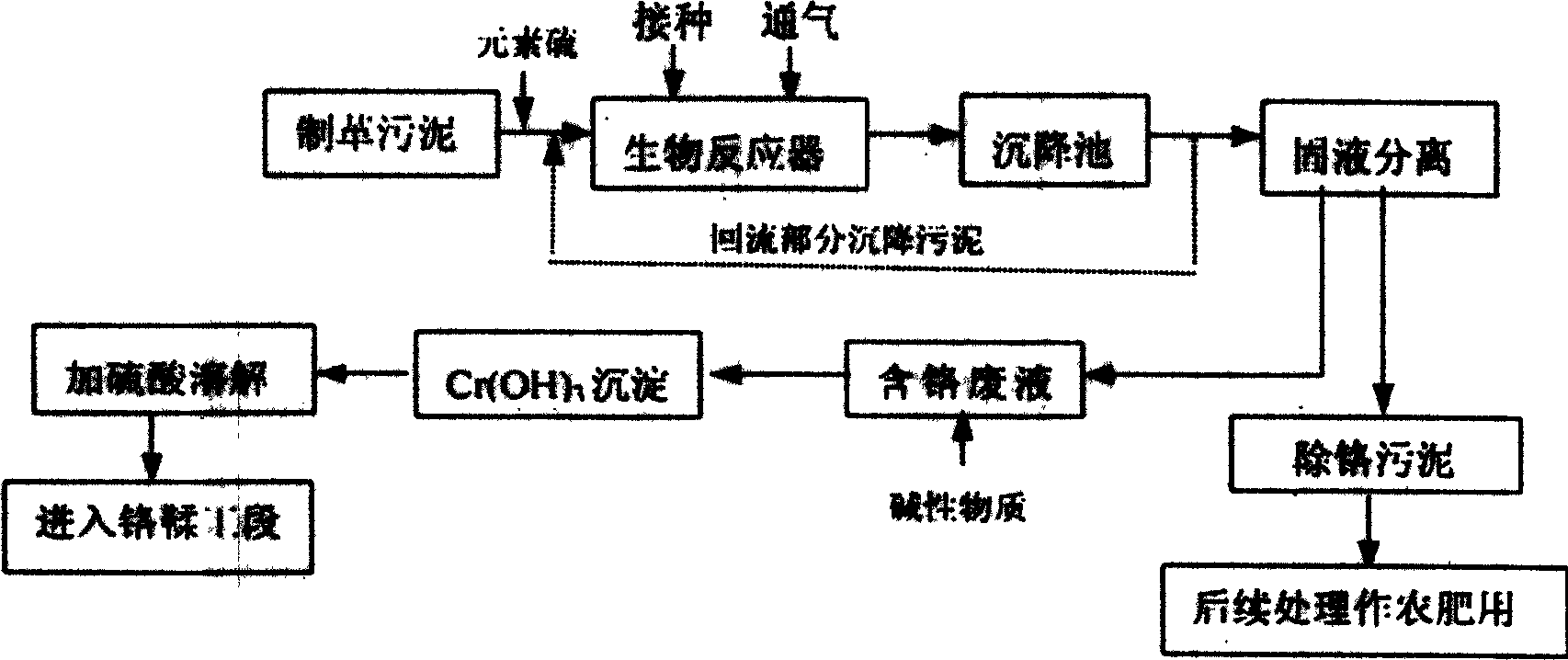

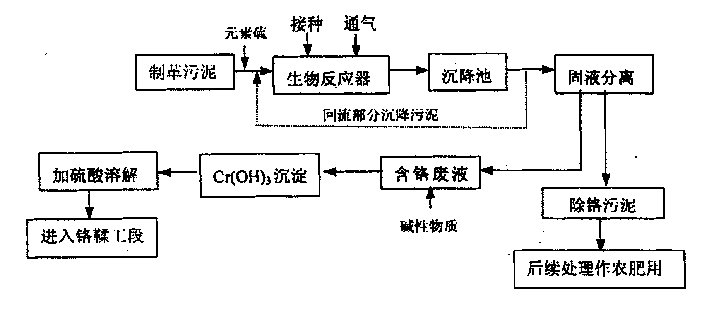

Method used

Image

Examples

Embodiment 1

[0028] (1) Sampling

[0029] The thickening tank sludge of a tannery wastewater treatment plant in Haining, Zhejiang Province was taken. The basic properties of the tannery sludge are shown in Table 1.

[0030] Table 1 Basic properties of leather sludge for trial

[0031] pH Cr Solid content NP Organic matter

[0032] mg / kg %

[0033] 8.05 15900 11.84 3.03 0.51 54.6

[0034] (2)TS6 Bacteria isolation and expansion culture:

[0035] Thiobacillus thiooxidans bacterial strain provided by the present invention is named as TS 6 , Classification number: Thiobacillus thiooxidans, has been preserved in the depository unit designated by the Chinese Patent Office - the General Microorganism Center of the China Microorganism Culture Collection Management Committee, the preservation date is July 4, 2002, and the preservation registration number is CGMCC NO.0759. The characteristics of the bacteria are: short rod-sha...

Embodiment 2

[0045] (1) Sampling:

[0046] Get the tannery sludge in the thickening tank of a certain tannery wastewater treatment plant in Haining, Zhejiang, which is the same as the sludge sample in Example 1.

[0047] (2)TS 6 Bacteria isolation and expansion culture:

[0048] With embodiment 1.

[0049] (3) Start-up and operation of the bioreactor

[0050] Add the above-mentioned non-dewatered tannery sludge to the bioreactor, add 1g / L elemental sulfur, and add the above-mentioned TS at the same time 6 10% (v / v) was stirred and ventilated to start the reaction of microorganisms to remove Cr, and when the pH of the tanning sludge in the bioreactor was reduced from 8.05 to 2.0 (3-5 days), the bioreactor was taken out The sludge in the sedimentation tank enters the settling tank for gravity settlement, and 15% (v / v) of the settled sludge is returned to the bioreactor, and the remaining 85% is separated from solid and liquid:

[0051] (4) Solid-liquid separation and recycling of chromi...

Embodiment 3

[0057] (1) Sampling:

[0058] Take undewatered sludge from a tannery in Nanjing, Jiangsu. The basic characteristics of the sludge are shown in Table 4.

[0059] Table 4 Basic characteristics of trial leather sludge

[0060] pH Cr Solid NP Organic

[0061] rate quality

[0062] mg / kg %

[0063] 7.55 19000 9.60 3.48 1.05 60.2

[0064] (2)TS 6 Bacteria isolation and expansion culture:

[0065] With embodiment 1.

[0066] (3) Start-up and operation of the bioreactor

[0067] Add the above non-dewatered sludge to the bioreactor, add 3g / L elemental sulfur, add the above TS 6 (10%, v / v) was stirred and ventilated to start the reaction of microorganisms to remove heavy metals. When the pH of the sewage sludge in the bioreactor was reduced from 7.55 to 2.0 (3-6 days), it could pass through the peristaltic pump Take out the sludge in the bioreactor, 20% (v / v) of the sludge is reflowed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com