Abrasive cloth and grinding method thereof

A technology of abrasive cloth and composite cloth, which is applied in the field of abrasive cloth and can solve problems such as difficult industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] 49.1 parts of polyethylene with a melt index of 90 measured at a temperature of 260° C., 50 parts of nylon 6 with a melt index of 18, and 0.9 parts of polyethylene glycol were mixed in a granular state. Next, the mixed pellets are fed into an extruder for spinning. The temperature of the melting part and the screw end was 260°C, the temperature of the spinning pack and the spinning die was 250°C, and the diameter of the hole of the spinning die was 0.3 mm. Furthermore, each mixed spun fiber was stretched, crimped mechanically, and then cut. The obtained mixed spinning fiber (main filament) was a fiber raw material having a fineness of 6.6 dtex and a length of 51 mm. Secondly, the fiber raw material is passed through the carding machine to become a fiber strand, and is processed into a complex fiber strand through needle punching. The fiber strand was passed through a heating zone at 140° C., and pressed with calender rolls to obtain a relative weight of 670 g / m 2 , F...

Embodiment 2

[0086] A polishing cloth was produced in the same manner as in Example 1 except that an immersion liquid of 5% solid content was used instead of the immersion liquid of 15% solid content polyurethane resin used in Example 1. The ratio of the polymer elastic body (polyurethane resin) to the fiber base material of the abrasive cloth was 5 / 95.

[0087] This polishing cloth was composed of ultrafine fibers as in Example 1. However, compared with the abrasive cloth of Example 1, the fluff was long, the uniformity of the surface was slightly inferior, the dispersion degree of thickness was 3.8, and the tensile strength was 8 N / cm.

[0088] Thereafter, when texture processing was performed in the same manner as in Example 1, scratches rarely occurred. Table 1 shows the physical properties of the obtained abrasive cloth and magnetic recording disk.

Embodiment 3

[0094] Except not grinding|polishing with sandpaper, it produced similarly to Example 1, and produced the non-fluff type polishing cloth.

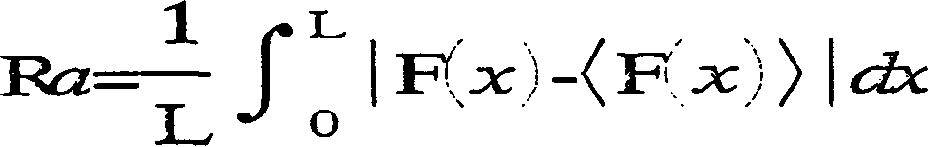

[0095] The obtained polishing cloth was used for texture processing in the same manner as in Example 1. The average surface roughness Ra of the hard disk was good, reaching 4.0 angstroms.

[0096] Table 2 shows the physical properties of the obtained abrasive cloth and magnetic recording disc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com