Continuous preparation of m-toluidine

A technology of m-cresol and cresol, which is applied in the field of continuous preparation of m-cresol, can solve the problems of hindering m-cresol reaction system, large amount of three wastes, long reaction cycle, etc. Low, shorten the effect of the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

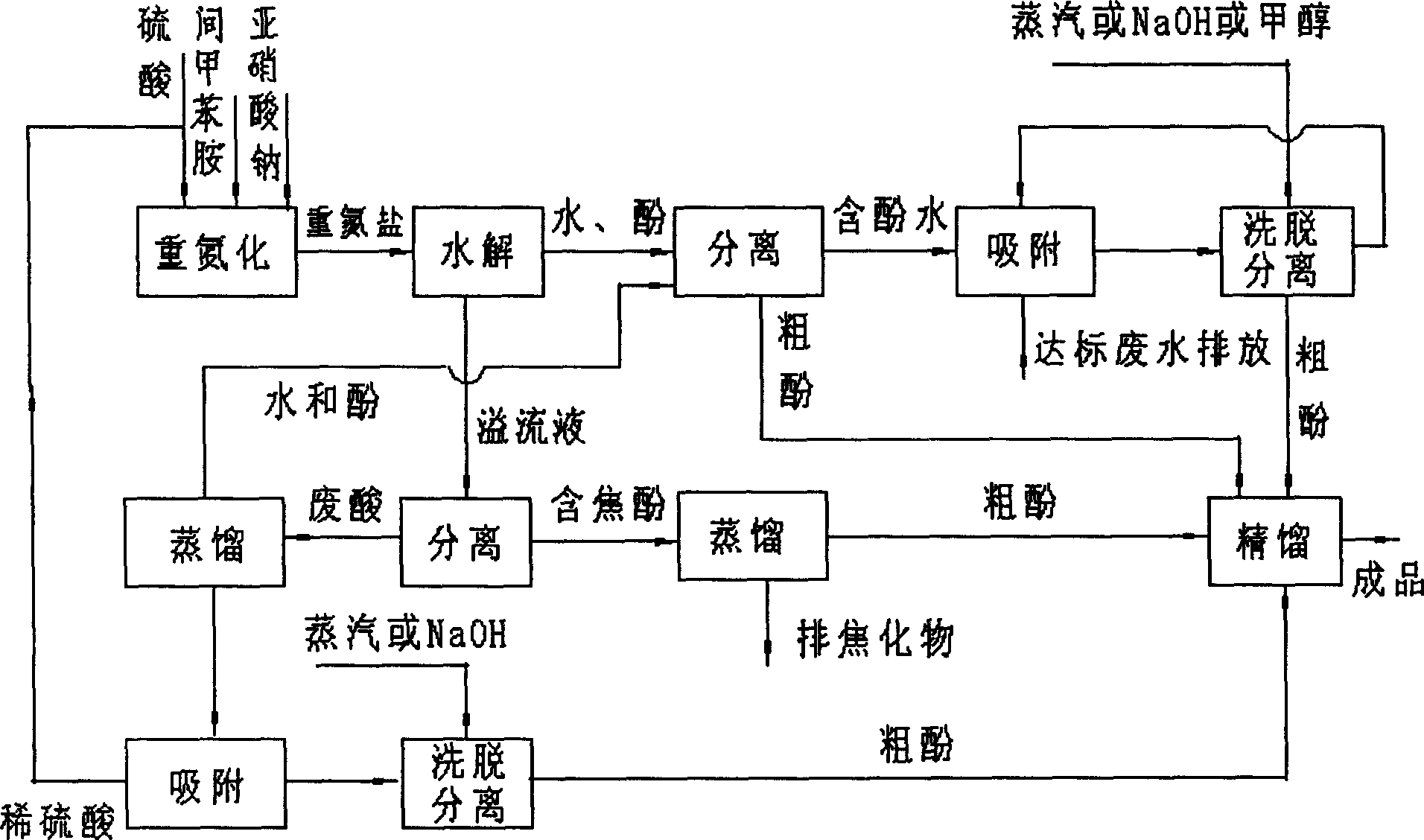

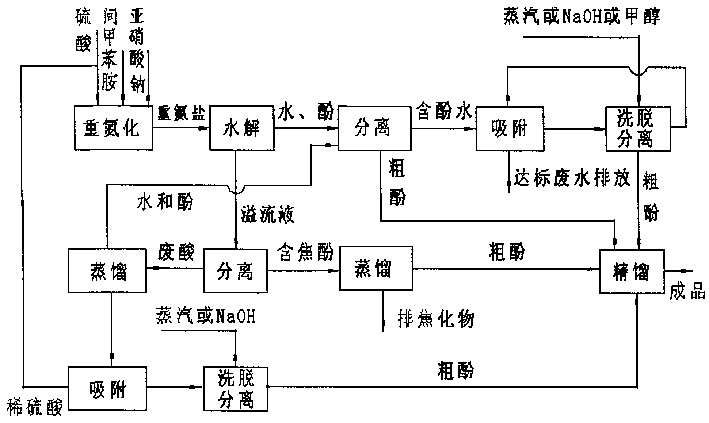

Image

Examples

Embodiment 1

[0016] Embodiment 1: The diazonium salt solution of m-toluidine is prepared alternately according to conventional method with more than two reaction kettles at 0-10°C. Referring to accompanying drawing, in the reactor of 500L, add the sulfuric acid 281kg of 20wt%, then add 25kg m-toluidine, keep reaction temperature 0~10 ℃ under agitation, add the solution that 17.5kg sodium nitrite is dissolved in 35kg water and pass heavy Nitriding reaction to prepare m-toluidine diazonium salt solution.

[0017] In the 500L hydrolysis reactor, add 300L of 30wt% sulfuric acid, at 105~110 ℃, the m-toluidine diazonium salt solution that above-mentioned making is continuously added in the hydrolysis reactor; The water vapor is continuously taken out by distillation, and at the same time, the dilute sulfuric acid and tar-like by-products with m-cresol are continuously overflowed from the upper overflow port of the reactor.

[0018] Separation of waste sulfuric acid and tar-like substances con...

Embodiment 2

[0021] Embodiment 2: m-toluidine diazotization is the same as embodiment 1; adopt the sulfuric acid of 50wt% to carry out hydrolysis reaction, and hydrolysis reaction temperature is 110~150 ℃; Phenol <0.02 g / L). The crude m-cresol was recovered by eluting with methanol. The waste sulfuric acid is used as raw material to prepare m-toluidine diazonium salt solution after being adsorbed by resin. The organic substances adsorbed on the resin are eluted with water vapor. 24.04kg of crude m-cresol with a content of 95-97wt% was obtained. The crude m-cresol was rectified to obtain 21.69 kg of finished m-cresol with a content ≥ 99.5%, and the yield was 85.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com