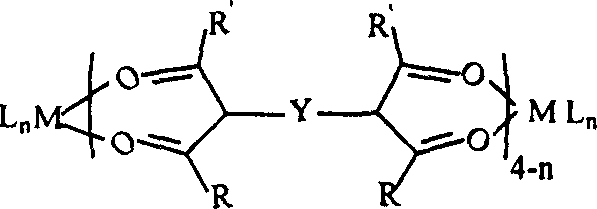

Binuclear beta-diketone catalyst for synthesizing syndiotactic polystyrene and its preparation method

A polystyrene and catalyst technology, applied in the field of dual-nuclear catalyst and its preparation, can solve the problems of low polymerization activity, and achieve the effects of low production cost, inhibition of bimolecular deactivation, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0026] Examples 1-12: Synthesis of catalyst components of the present invention, and their properties are shown in Table 1.

[0027]

Reality

Example

R

R’

-Y-

main catalyst

Al / T

i(Ni)

T

(℃)

activity

(10 5 gPS /

molTi(Ni) h)

between

gauge

%

T m

(℃)

1

2

3

4

5

7

8

9

10

11

12

CH 3

CH 3

CH 3

CH 3

CH 3

CH 3

C 6 h 5

C 6 h 5

C 6 h 5

C 6 h 5

C 6 h 5

C 6 h 5

CH 3

CH 3

CF 3

CH 3

CH 3

CH 3

C 6 h 5

C 6 h 5

CF 3

C 6 h 5

C 6 h 5

C 6 h 5

-(CH 2 ) 6 -

-

-C 6 h 4 -

-(CH 2 ) 10 -

-(1,4-(CH 2 ) 2 C 6 h 4 )-

-(2,6-dmp)-

-

-(2,4-dmp)-

-C 6 h 4 -

-C 6 h 4 - ...

Embodiment 1

[0032] In a 100ml two-necked flask equipped with a stirrer, add 20ml of ethanol and 2.3g of alkali metal sodium, under the reflux temperature of ethanol, add 1.5g of acetylacetone and 2g of dichlorohexane respectively, react for 2 hours, filter and dry to obtain the ligand ( CH 3 CO) 2 CH-(CH 2 ) 6 -CH(COCH 3 ) 2 0.85g. N at 0°C 2 Dissolve 0.5g of the ligand in ether solution and add to the solution containing 1.5ml of Ti(OPh) 4 Carry out complex coordination in the diethyl ether solution, when the temperature reaches room temperature, then raise the temperature to the solvent reflux temperature, reflux for 6 hours, filter and wash the precipitate, and vacuum dry to obtain the main catalyst A 2 [Ti(OPh) 2 ] 2 (A=(CH 3 CO) 2 CH-(CH 2 ) 6 -CH(COCH 3 ) 2 ) 0.46g. In a 100ml two-necked flask replaced by nitrogen and equipped with a stirrer, add 15ml of toluene distilled by reflux of metal sodium, stir and raise the temperature to 20°C, add the main catalyst A 2 [...

Embodiment 2

[0034] In a 100ml two-necked flask equipped with a stirrer, add 20ml of ethanol and 2.3g of alkali metal sodium, and at the reflux temperature of ethanol, add 1.5g of acetylacetone and 2g of potassium iodide respectively, react for 2 hours, filter and dry to obtain the ligand (CH 3 CO) 2 CH-CH (COCH 3 ) 2 0.63g. N at 0°C 2 Dissolve 0.4g of the ligand in ether and add to the solution containing 1.5ml of TiCl 4 Carry out complexation and coordination in the diethyl ether liquid, when the temperature reaches room temperature, then raise the temperature to the solvent reflux temperature, reflux for 6 hours, filter and wash the precipitate, and vacuum dry to obtain the main catalyst A (TiCl 3 ) 2 (A=(CH 3 CO) 2 CH-CH (COCH 3 ) 2 ) 0.26g. In a 100ml two-necked flask replaced by nitrogen and equipped with a stirrer, add 15ml of toluene distilled by metal sodium reflux, heat up to 80°C under stirring, add the main catalyst A (TiCl 3 ) 2 19.69mg (the concentration is 1×10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aggregation | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com