Technique for fabricating color decorative glass sheet

A decorative glass and production method technology, applied in glass production, glass molding, glass blowing, etc., can solve the problems of not being able to blow large glass balls, and achieve the effects of not being easily broken, reducing costs, and operating quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Take 60 kg of quartz sand, 28 kg of soda ash as flux, 5.5 kg of borax, 0.7 kg of cadmium red, 0.4 kg of cadmium yellow, 0.1 kg of selenium powder, 3 kg of potassium carbonate and 2 kg of zinc oxide for stirring, and hydrogen brightener Alumina is 0.3 kg, and the total feeding amount is 100 kg.

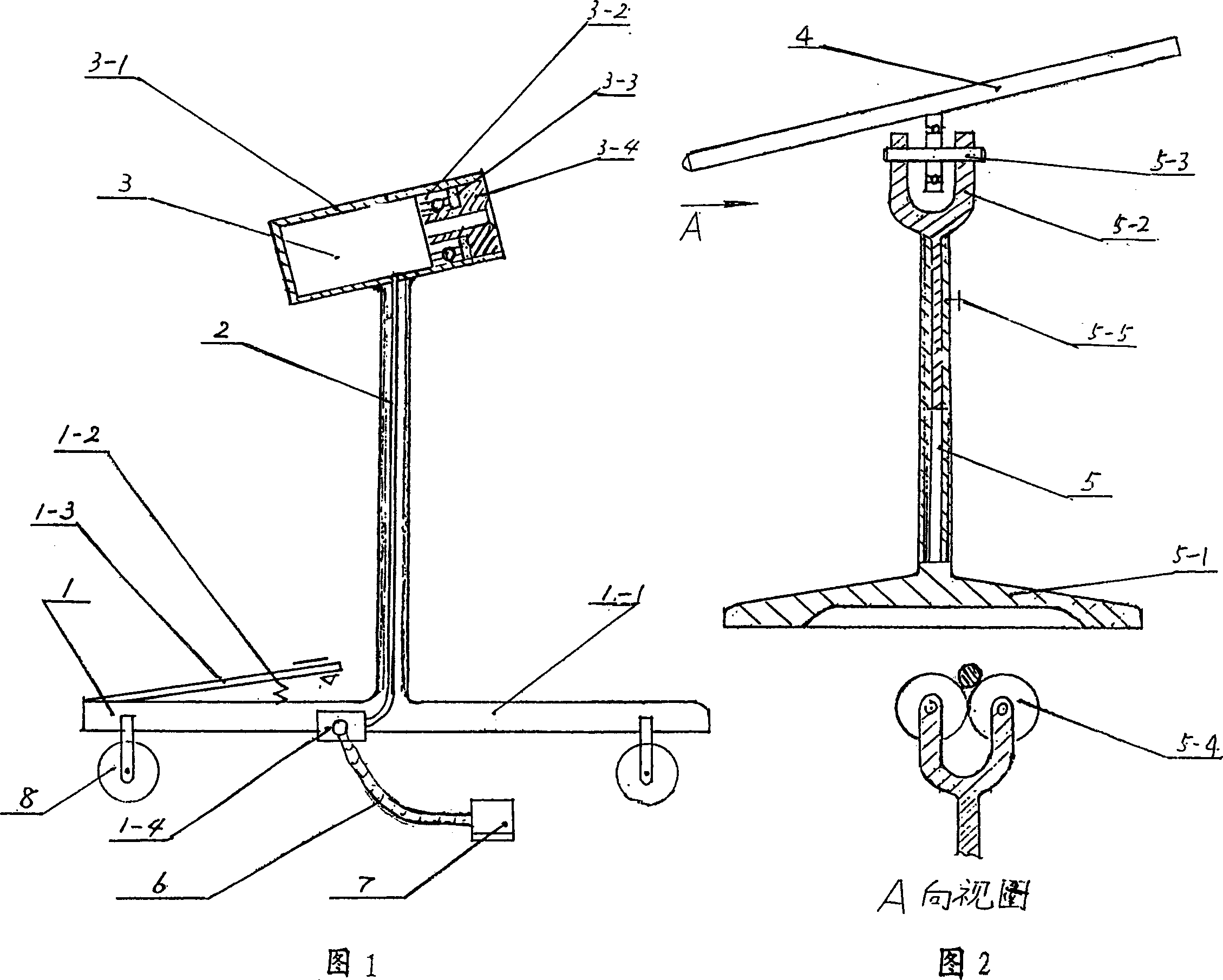

[0058] After mixing the above raw materials, smelt it into fluid glass at a high temperature of 1500℃ in a crucible furnace. Use one end of the blowpipe 4 to blow the fluid glass into small glass balls, and insert the other end into the gas nozzle 3-4. The blowing device blows the small ball into a large glass sphere with a curvature of 200°. After cooling, the glass ball is broken into a rectangular spherical colored decorative glass piece with four corners of 90°, length 90mm, width 70mm, and thickness 0.3mm. , Which is made into red decorative glass products.

[0059] The structure of the above-mentioned blowing device for manufacturing spherical decorative glass and its blowing ...

Embodiment 2

[0067] Take 80 kilograms of quartz sand, 15.7 kilograms of flux soda ash and 2 kilograms of sodium nitrate, 5 grams of colorant cobalt oxide, 2 kilograms of borax, 0.29 kilograms of antimony oxide as a sedimentation agent, and 100 kilograms of total material.

[0068] The smelting temperature is 1300°C, and the spherical decorative glass blowing device is used to blow glass balls with a spherical curvature of 180°. The glass sheet has a thickness of 0.5 mm and the back surface is silver-plated. The rest are the same as in Example 1. The product is blue decorative glass.

Embodiment 3

[0070] Take 35 kilograms of quartz sand, 10 kilograms of soda ash as flux, 2 kilograms of cadmium yellow as colorant, 3 kilograms of borax, 3 kilograms of potassium carbonate as propping agent, 4 kilograms of brightener aluminum hydroxide, and the rest is clinker. The total amount of feed is 100 kilograms.

[0071] The smelting temperature is 1400°C, and a glass ball with a spherical curvature of 150° is blown by a blowing device for making spherical decorative glass. The glass sheet has a thickness of 1.1 mm. The rest is the same as in Example 1. The product is a yellow decorative glass sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com