Magnesium sulfate production method using magnesium oxide and desulfurated waste fluid

A technology for desulfurization waste liquid and magnesium sulfate, applied in magnesium sulfate, chemical instruments and methods, separation methods, etc., can solve the problems of difficult practical operation, low calcium sulfate products, difficult separation of calcium sulfate particles and magnesium hydroxide, etc. Significant social benefits, small evaporation, excellent energy consumption and quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

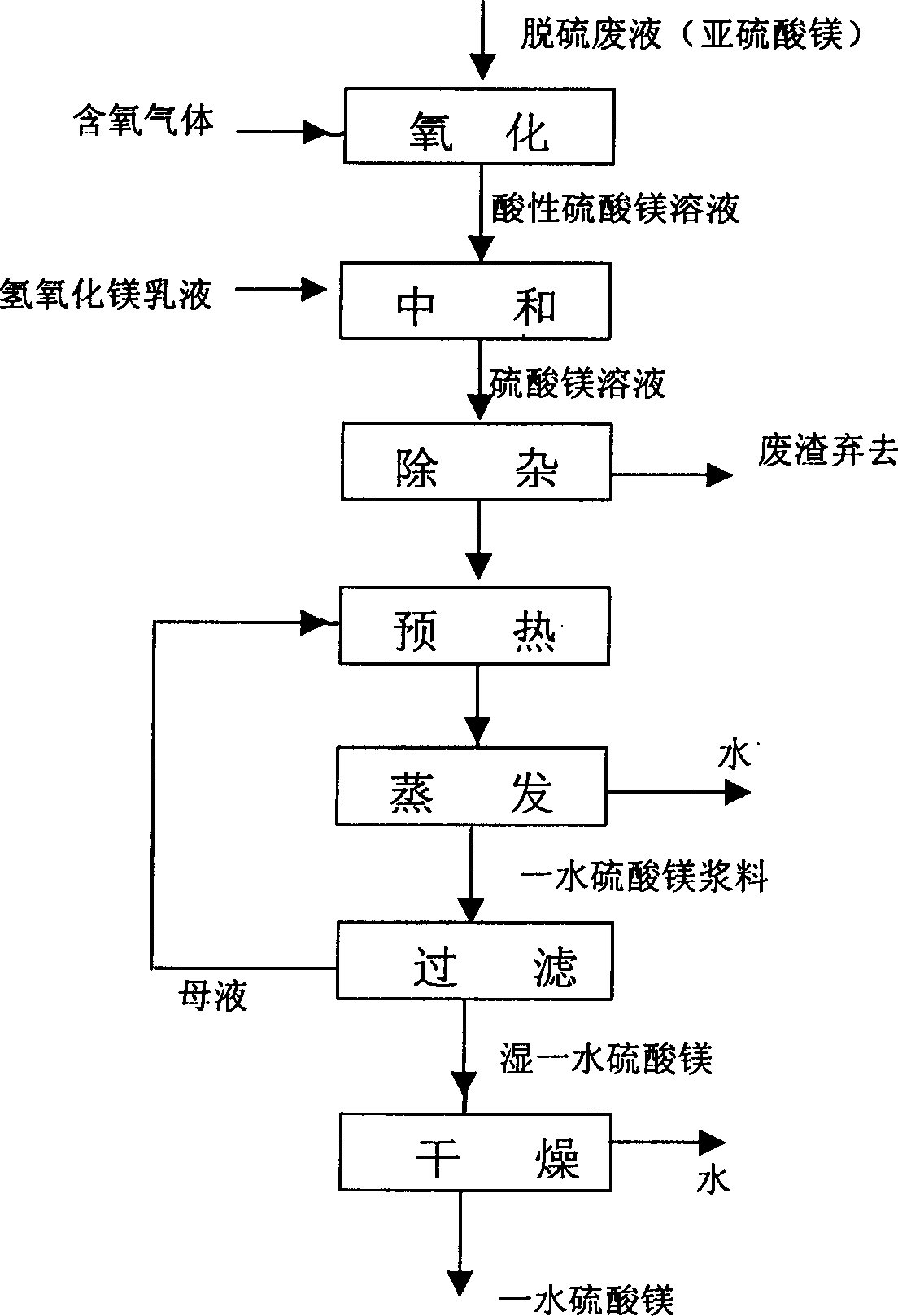

[0032] ① Oxidation: Take 2000g of magnesium oxide desulfurization waste liquid containing 20% magnesium sulfite (prepared by magnesium sulfite reagent) and put it into a beaker with stirring, heat to 35°C, blow air in for 30 minutes, take a sample and analyze magnesium sulfate It reaches 22.2%, and the oxidation rate reaches 99%. The pH value of the solution is 6-7, and the process of neutralization and impurity removal is omitted.

[0033] ② Evaporation concentration and separation: Put 2055g of the above solution on the electric furnace and heat it while stirring. Continue at 125°C for 10 minutes, lose 1040g of water, stop heating, let it stand for 2 minutes, quickly pour the supernatant liquid into another beaker, take The lower floor slurry is filtered and dried with a filter cloth bag to obtain 366g of wet magnesium sulfate monohydrate, and the mother liquor and supernatant liquid thrown out are poured into the same beaker.

[0034] ③Drying: disperse 360g of wet magnes...

Embodiment 2

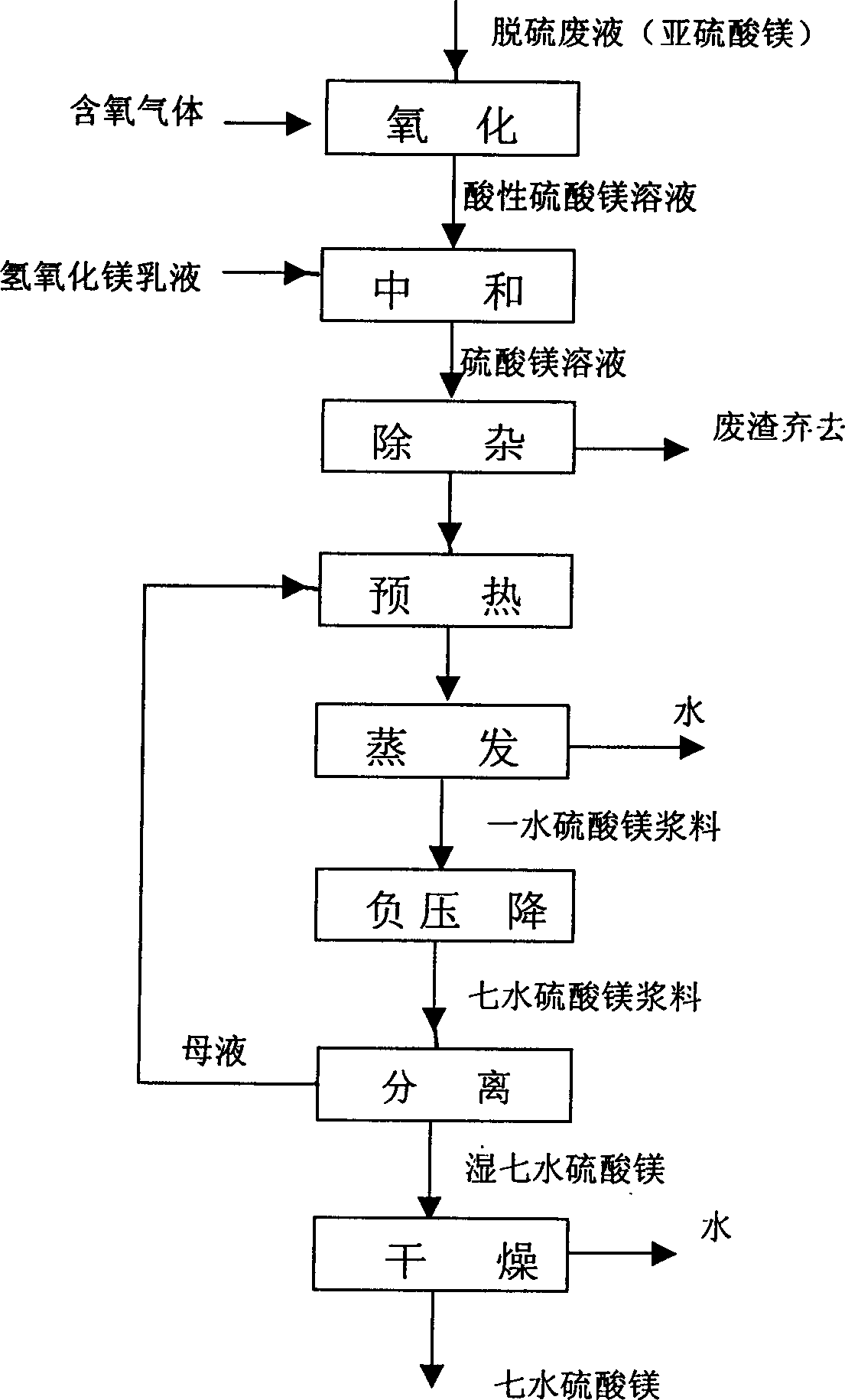

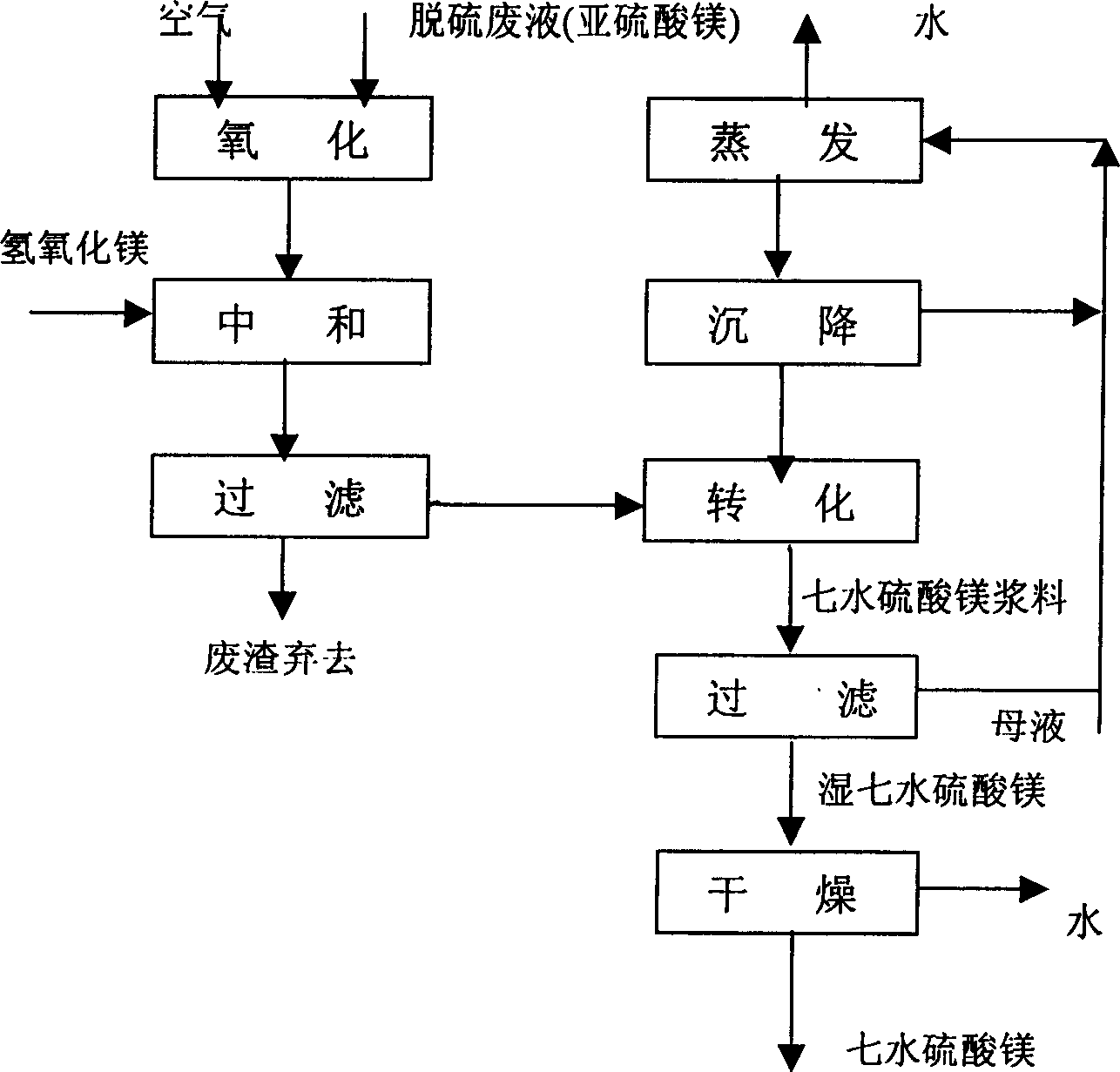

[0037] ① Take 1000 grams of waste liquid containing 25% magnesium sulfite produced by the magnesium oxide wet desulfurization process, feed air into it for 30 minutes, then add 8 grams of 50% magnesium hydroxide emulsion, stir for 30 minutes, and the pH Be 7, filter then, obtain 3 gram filter cakes, 1028 gram supernatants. Prepare two more supernatants in the same way.

[0038] 2. Put the above 1028 grams of clear liquid into a beaker, evaporate at a temperature of 120°C, remove 300 grams of water, settle for 20 hours, pour out 400 grams of clear liquid to obtain 328 grams of magnesium sulfate slurry.

[0039] ③Get 1028 grams of clear liquid again, add 328 grams of magnesium sulfate slurry obtained above, stir for 4 hours at 25°C, then filter to obtain 300 grams of wet magnesium sulfate heptahydrate, obtain 1056 grams of filtrate, and pass through 50 grams of wet magnesium sulfate heptahydrate. ℃ hot air drying to obtain 290 grams of dry magnesium sulfate heptahydrate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com