Method for forming film by using atomic layer deposition method

A technique of atomic layer deposition and atomic layer, which is applied in chemical instruments and methods, coatings, metal material coating processes, etc., can solve the problems of damaging the properties of insulating films and not being able to obtain thin film properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

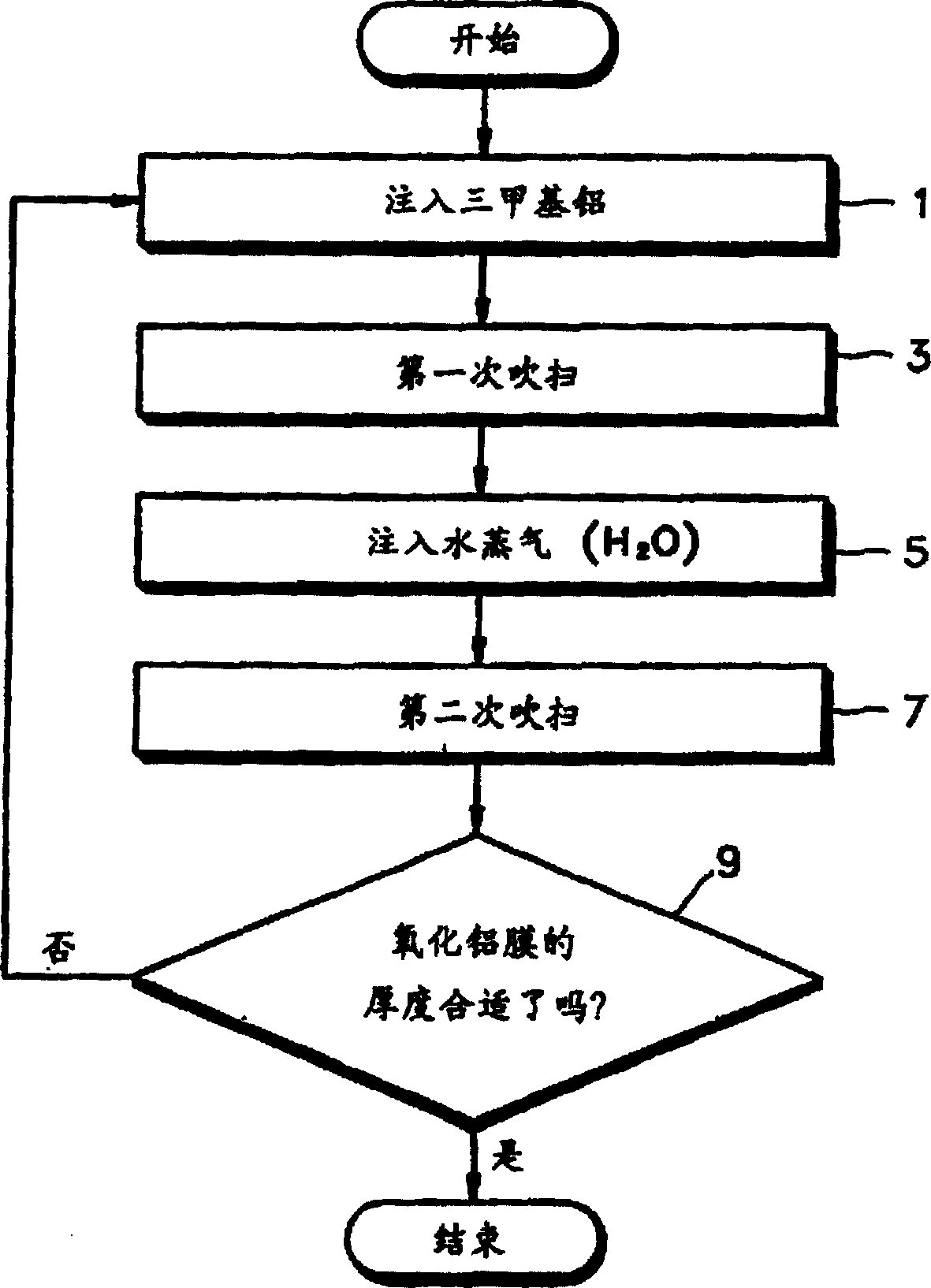

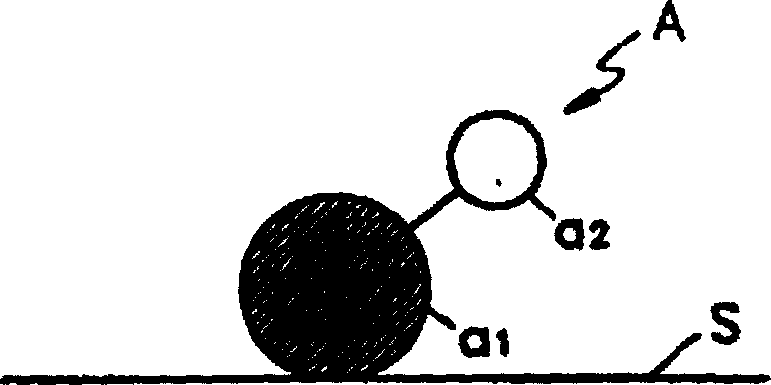

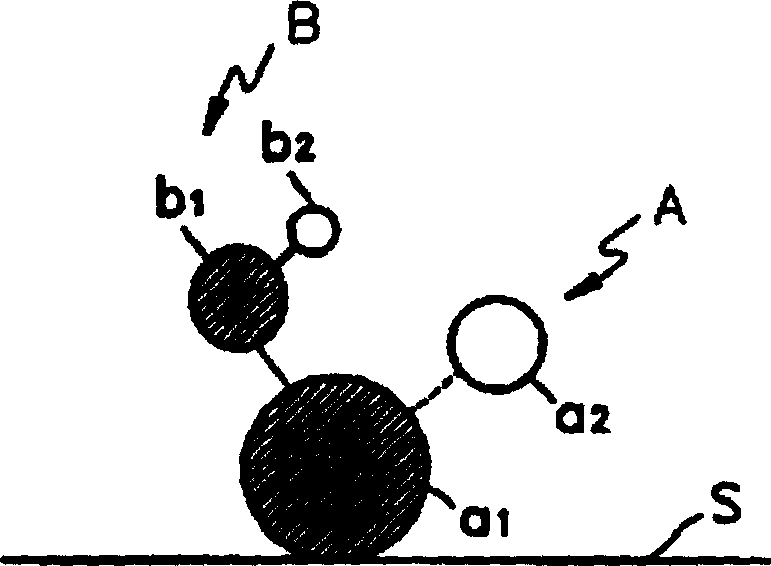

[0058] Figure 4A to Figure 4D The reaction mechanism of the method of forming a thin film using the ALD method according to the first embodiment of the present invention is shown. By injecting the first reactant A into the reaction chamber 11 equipped with the substrate, the first reactant is chemisorbed into the substrate 15 such as the silicon substrate, wherein the first reactant consists of the atoms a forming the film 1 and ligand a 2 After the first reactant A is adsorbed into the substrate 15, the first reactant A physically adsorbed is removed by injecting an inert gas to purge the reaction chamber ( Figure 4A ).

[0059] The second reactant B is injected into the reaction chamber 11 containing the substrate where the first reactant A has been adsorbed. Thus, the second reactant B is chemisorbed into the first reactant A. An imperfect material that actively reacts with the first reactant A is used as the second reactant B. A substance is used as the second react...

no. 2 example

[0095] Figure 22 A flowchart showing a second embodiment of the method of forming a thin film using the ALD method according to the present invention. Rinse the substrate with oxygen ( image 3 In 15), for example, a silicon substrate using an oxidizing gas, the dangling bonds of the substrate 15 are combined with oxygen to perform a termination treatment (step 21). That is, at any point where oxygen can bind to the substrate 15, by flushing the substrate with oxygen ( image 3 In 15) oxygen is bound to the substrate, for example flushing the silicon substrate with an oxidizing gas.

[0096] The dangling bonds can be combined with oxygen, that is, not only by oxygen rinsing, but also by ozone rinsing and by forming a silicon oxide film so that oxygen is bound to any available site on the substrate. In addition, no oxygen flushing may be performed on the substrate 15 .

[0097] Substrate 15 is loaded into reaction chamber ( image 3 In 11) after, utilize heater (not shown...

no. 3 example

[0119] Figure 26 A flowchart showing a method of forming a thin film by the ALD method according to the third embodiment of the present invention. Figure 27 is a timing chart showing the supply of reactants during thin film formation by the ALD method of the third embodiment of the present invention. In the following description, the formation of an aluminum oxide film is taken as an example.

[0120] Oxygen cleaning or nitrogen cleaning is performed on the substrate 15 with an oxidizing gas or a nitriding gas, so that the dangling bonds of the substrate are terminated, and the substrate may be a silicon substrate (step 41 ). That is, at any point where oxygen can bind to the substrate, the substrate can be a silicon substrate, by using an oxidizing gas or a nitriding gas to bind oxygen to the substrate by oxygen flushing or nitrogen flushing. Not only can use image 3 The atomic layer thin film forming apparatus is shown, and other apparatuses may be used for oxygen flus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com