Cell culture device

A cell culture and cell technology, applied in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve problems such as unsatisfactory, fluid shear stress interference, and reduced cell viability, to prevent negative effects. Influence, reduce contamination, enhance the effect of cell adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

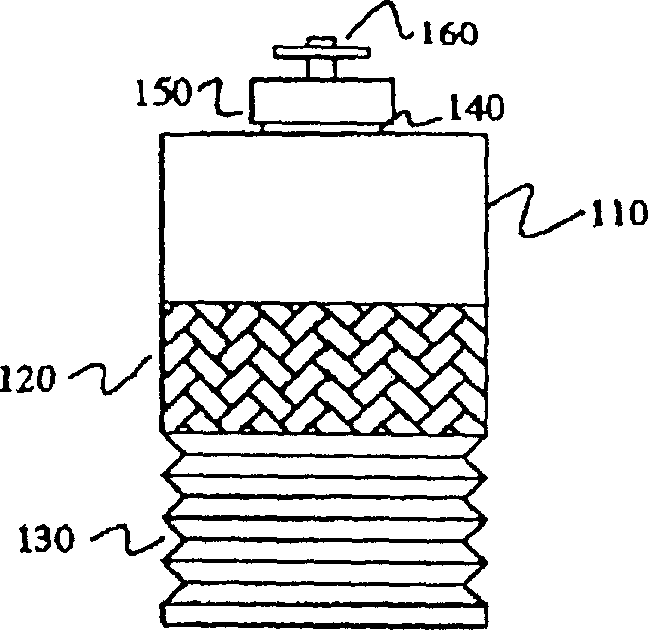

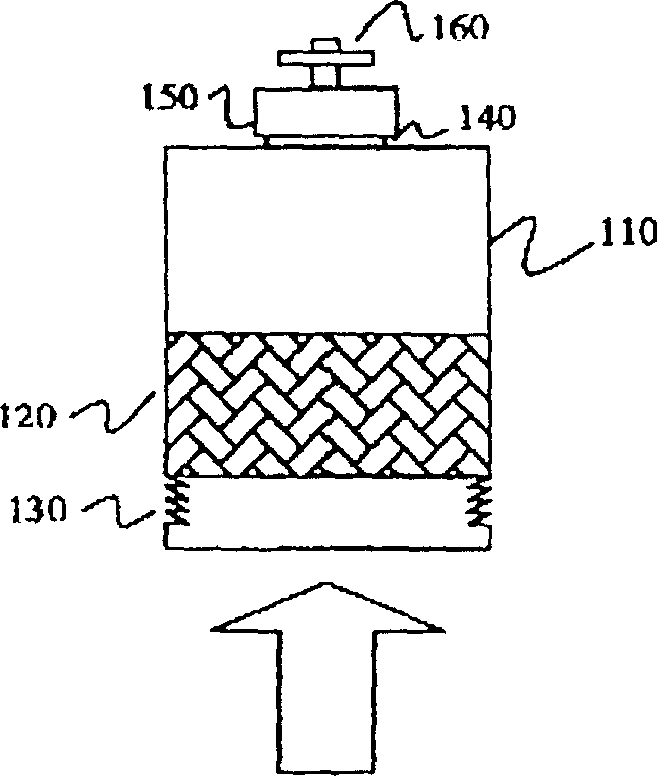

[0183] refer to Figure 1-Figure 2 As shown, Embodiment 1 of the device of the present invention includes that the first chamber 110 contains a growth substrate 120, and the growth substrate 120 can be made of any material, for example: ceramics, biodegradable matrix, high molecular polymer, woven substrate (woven substrate), non-woven substrate, polyamide, polyester, polyurethane, fluorocarbon polymer, polyethylene, polypropylene or polyvinyl alcohol, tri-methylamine, glass, silicon With diethylaminoethyl (DEAE). The growth substrate 120 can optionally be porous, and the growth substrate 120 of the present invention can be used for cell attachment, and the attached cells can obtain oxygen without being directly exposed to the air environment. Direct exposure to air can cause injury and death to cells, especially animal and mammalian cells, and loss of culture viability.

[0184] The growth substrate 120 can be in any form, shape or size, including, but not limited to, discs...

Embodiment 2

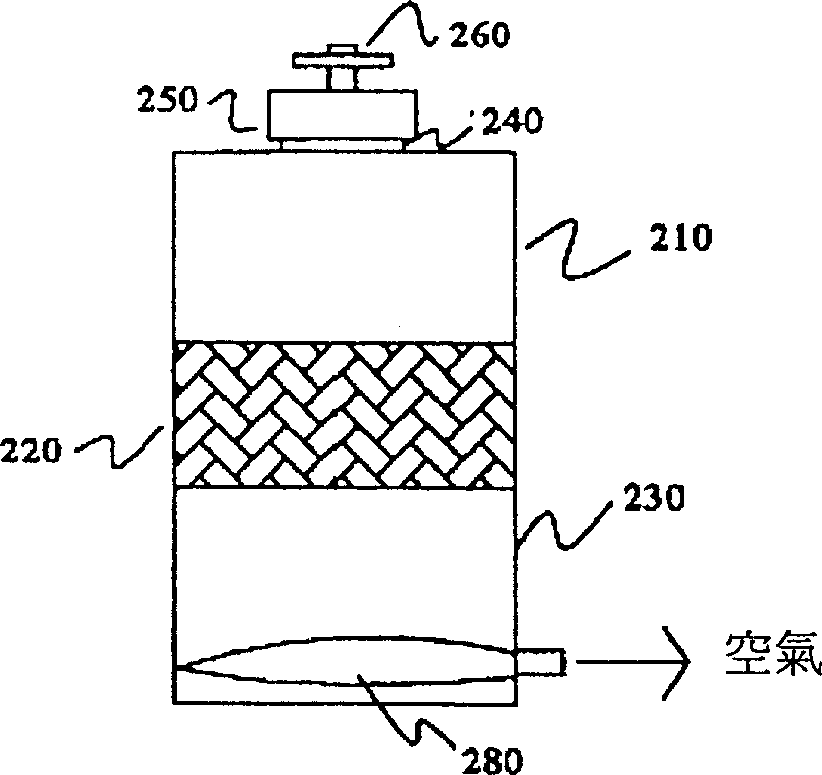

[0189] refer to Figure 3-Figure 4 As shown, Embodiment 2 of the device of the present invention includes that the first chamber 210 contains a growth substrate 220, and the growth substrate 220 can be composed of a loosely assembled matrix, and its materials include but are not limited to: ceramics, biodegradable matrix, Polymers, woven substrates, non-woven substrates, polyamides, polyesters, polyurethanes, fluorocarbon polymers, polyethylene, polypropylene or polyvinyl alcohol, trimethylamine, glass, silicon and diethylaminoethyl.

[0190] The growth substrate 220 in embodiment 2 can optionally be porous, and the cells attached to the growth substrate 220 can obtain oxygen, but will not be directly exposed to the air environment. Direct exposure to air can cause injury and death to cells, especially animal cells and / or mammalian cells, and loss of viability in culture.

[0191] Growth substrate 220 can be any particle in any form, shape, or size, including, but not limited...

Embodiment 3

[0197] refer to Figure 5-Figure 6 As shown, Embodiment 3 of the device of the present invention includes that the first chamber 310 contains a growth substrate 320, and the growth substrate 320 can be composed of a loosely assembled matrix, and its materials include but are not limited to: ceramics, biodegradable matrix, Polymers, woven substrates, nonwoven substrates, polyamides, polyesters, polyurethanes, fluorocarbon polymers, polyethylene, polypropylene or polyvinyl alcohol, trimethylamine, glass, silicon and diethylaminoethyl. The growth substrate 320 in embodiment 3 can optionally be porous or a loosely assembled matrix that can be composed of particles. The porous growth substrate 320 can make the cells attached to it obtain oxygen, but it will not be directly exposed. in the air environment. Because direct exposure to air may cause injury and death to cells, especially animal cells and / or mammalian cells, and loss of viability in culture.

[0198]Growth substrate 32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com