Bronze plating additive, method for making same and use in bronze plating on tread band steel wire

A technology of bronze plating and additives, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve problems such as environmental protection difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

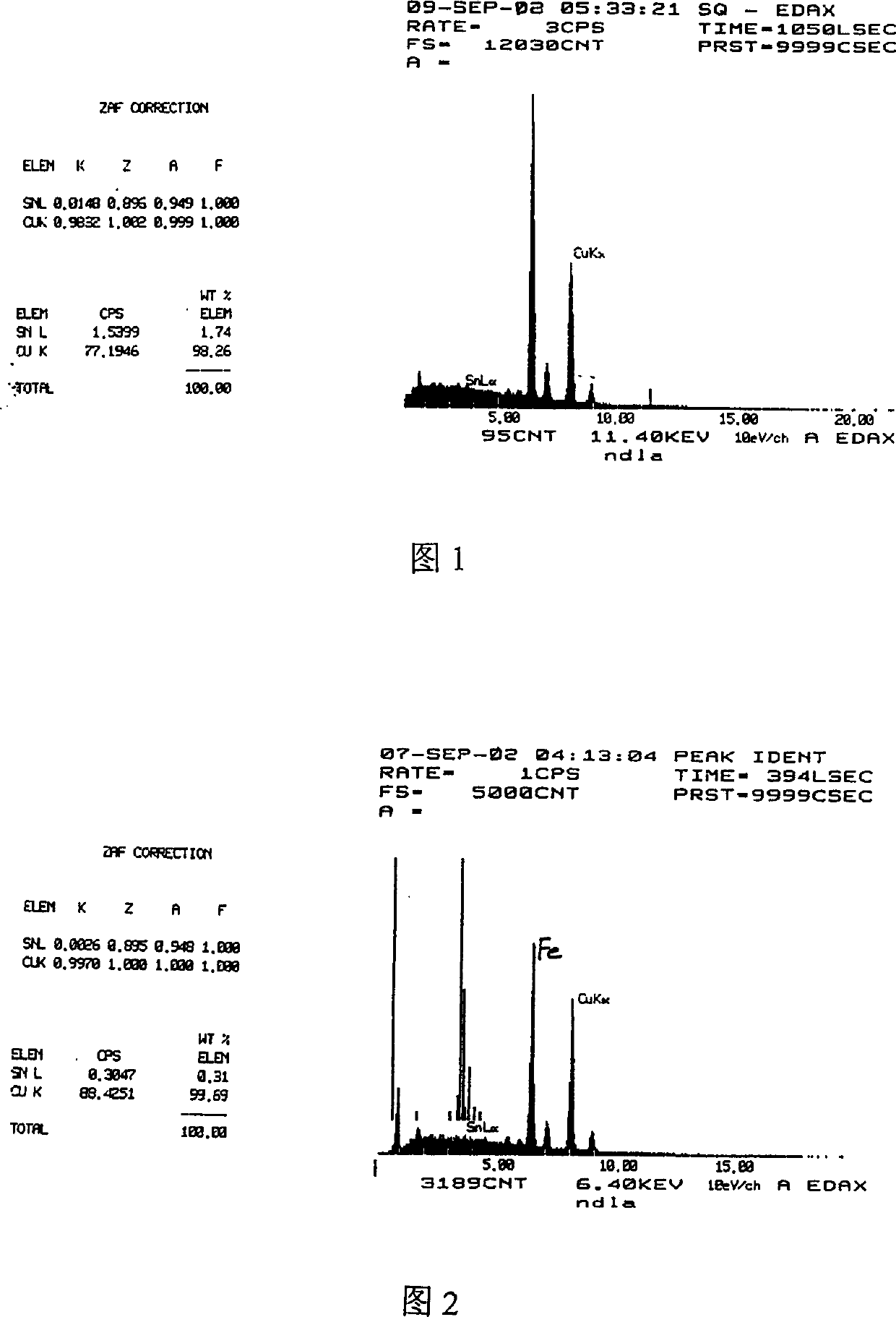

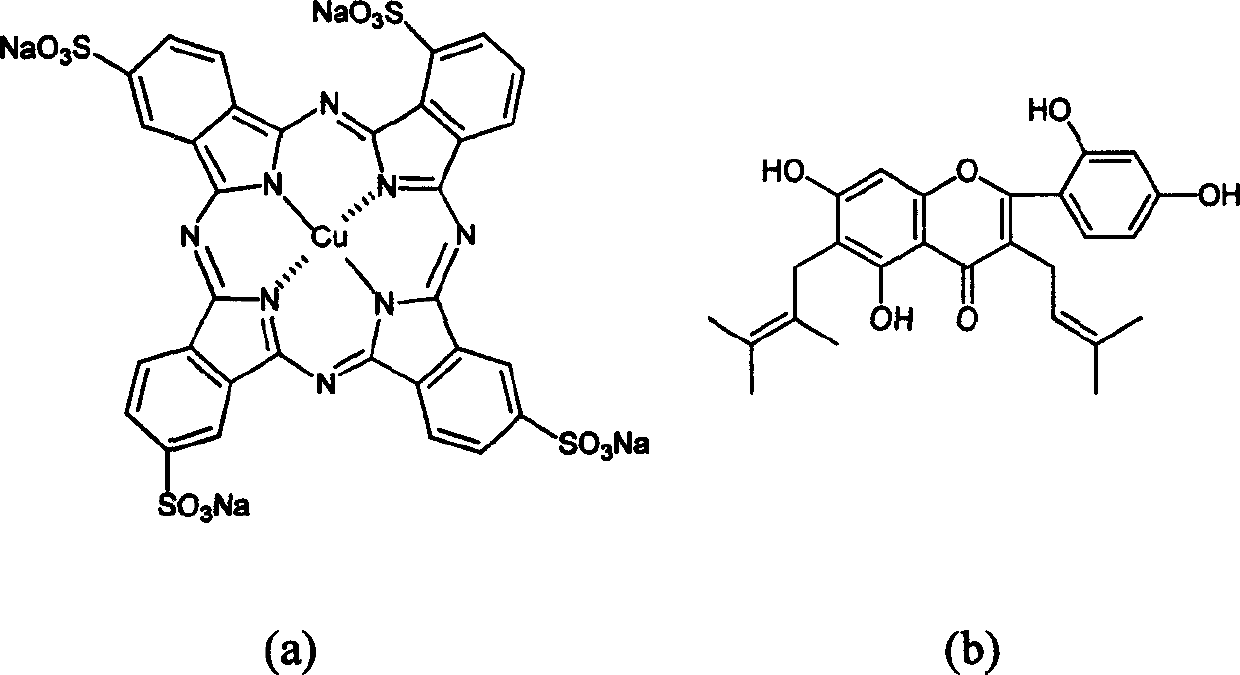

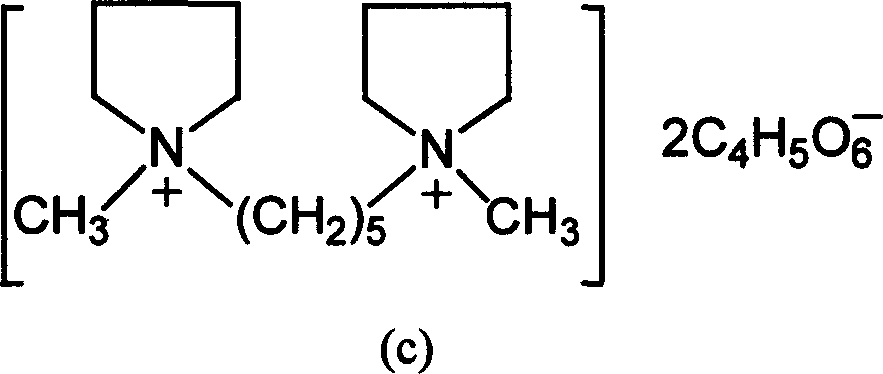

[0037] (1) After tetraphenylporphyrin is weighed, add in the sulfuric acid of 98% concentration of its weight 20 times, be heated to 140 ℃, heat 10 hours, be cooled to 35 ℃, then by weight ratio tetraphenylporphyrin: 3,4′,4″,4- tetrasodium copper phthalocyanine tetrasulfonate:sanbetin=1:1.5:0.5, 3,4′,4″,4- tetrasodium copper phthalocyanine tetrasulfonate Add mulperin into the above solution, stir evenly, and let it stand for 7 days to make the first component; dissolve sodium polydithiodipropane sulfonate in water, dissolve 2-mercaptobenzimidazole in ethanol, and dissolve dimethylol Dithiourea is dissolved in water, 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate is dissolved in water, according to sodium polydithiodipropane sulfonate: 2-mercaptobenzimidazole: dihydroxy Methylthiourea: 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate = 1:0.2:0.9:0.7 by weight and mixed to obtain the second component; Alcohol 6000: Sodium dodecylbenzene sulfonate: ...

Embodiment 2

[0043] (1) Tetraphenylporphyrin is weighed, add in the sulfuric acid of 98% concentration of 30 times of weight, be heated to 150 ℃, heat 8 hours, when cooling to 30 ℃ again, then by weight ratio tetraphenylporphyrin: 3,4′,4″,4-tetrasodium copper phthalocyanine tetrasulfonate:sanbetin=1:0.8:1, 3,4′,4″,4-tetrasodium copper phthalocyanine tetrasulfonate and mulperein were added to the above solution, stirred evenly, and left to stand for 6 days to make the first component; dissolving sodium polydithiodipropanesulfonate in water, 2-mercaptobenzimidazole in ethanol, dimethylol Dithiourea is dissolved in water, 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate is dissolved in water, according to sodium polydithiodipropane sulfonate: 2-mercaptobenzimidazole: dihydroxy Methylthiourea: 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate = 1:0.5:0.6:0.1 by weight and mixed to obtain the second component; Alcohol 6000: Sodium dodecylbenzene sulfonate: Alkyl poly...

Embodiment 3

[0049] (1) tetraphenylporphyrin is weighed, add in the sulfuric acid of 98% concentration of 30 times of weight, be heated to 160 ℃, heat 6 hours, when cooling to 40 ℃ again, then by weight ratio tetraphenylporphyrin: 3,4′,4″,4-tetrasodium copper phthalocyanine tetrasulfonate:sanbetin=1:1:0.8, 3,4′,4″,4-tetrasodium copper phthalocyanine tetrasulfonate Add mulperin into the above solution, stir evenly, and let it stand for 5 days to make the first component; dissolve sodium polydithiodipropane sulfonate in water, dissolve 2-mercaptobenzimidazole in ethanol, and dissolve dimethylol Dithiourea is dissolved in water, 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate is dissolved in water, according to sodium polydithiodipropane sulfonate: 2-mercaptobenzimidazole: dihydroxy Methylthiourea: 1,1'-pentamethylenebis(1-methyl)pyrrolidine hydrogen tartrate = 1:0.5:0.7:0.4 by weight and mixed to obtain the second component; Alcohol 6000: sodium dodecylbenzenesulfonate: alky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com