Method of producing a sheet comprising through pores and the application thereof in the production of micronic and submicronic filters

A through-hole and masking layer technology, applied in the production of through-hole foil and its application in the production of micron and sub-micron filters, can solve the problems of high raw material cost, unstable corrosion resistance, limitations, etc., and achieve high Productivity, high separation reliability, effect of eliminating clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

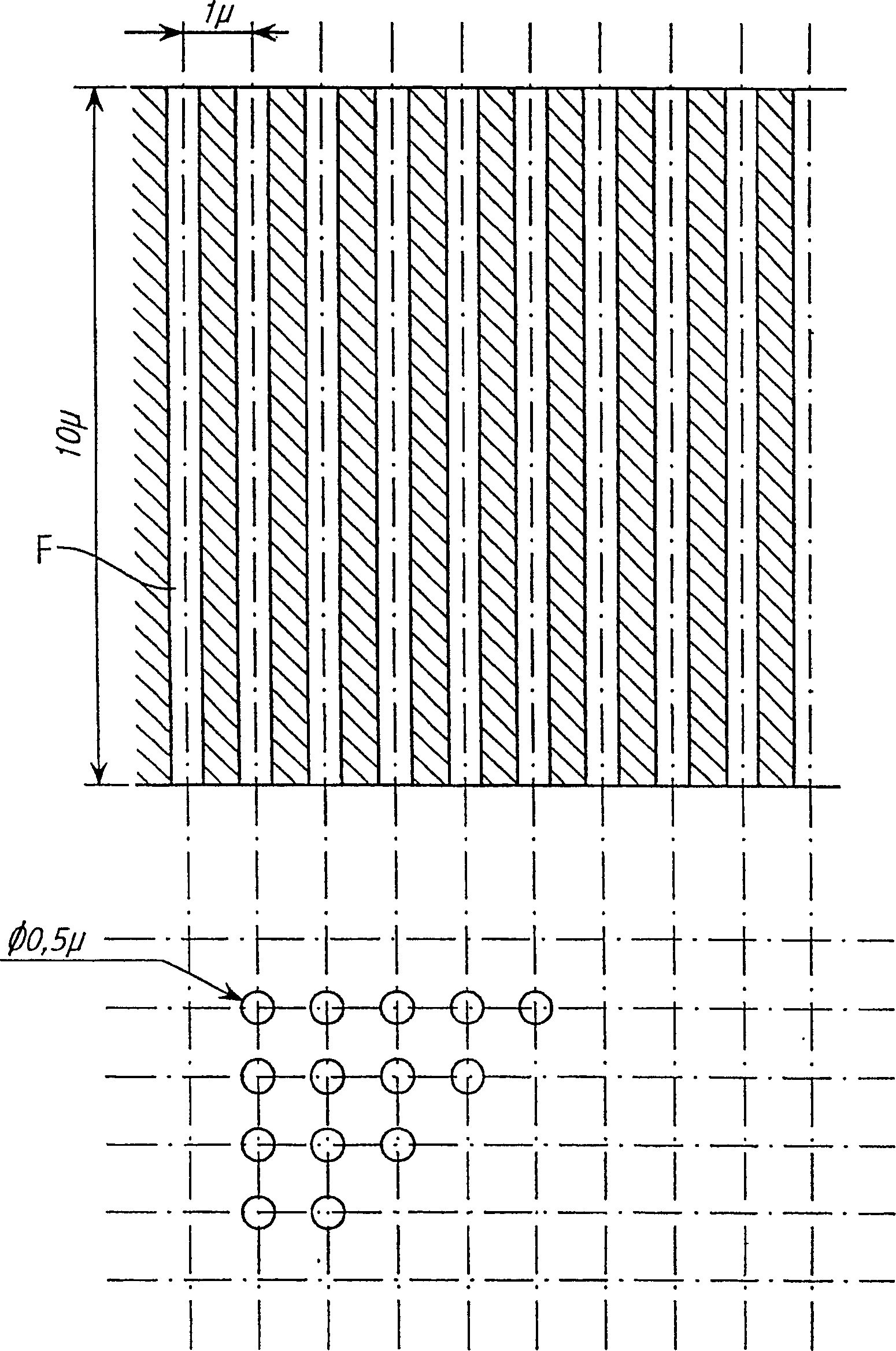

[0067] exist figure 1 , the upper part of the figure is a vertical cross-sectional view of a part of the foil including the cells, and the lower part of the figure is a partial top view of the foil.

[0068] As an example, the foil is a metal foil, such as molybdenum foil, having a thickness of 10 microns, and the holes form a square grid (array), each hole having a diameter of 0.5 microns and a depth of 10 microns (i.e. a form factor of 20) , the interval is 0.5 microns, that is, the unit area density is 10 8 hole / cm 2 .

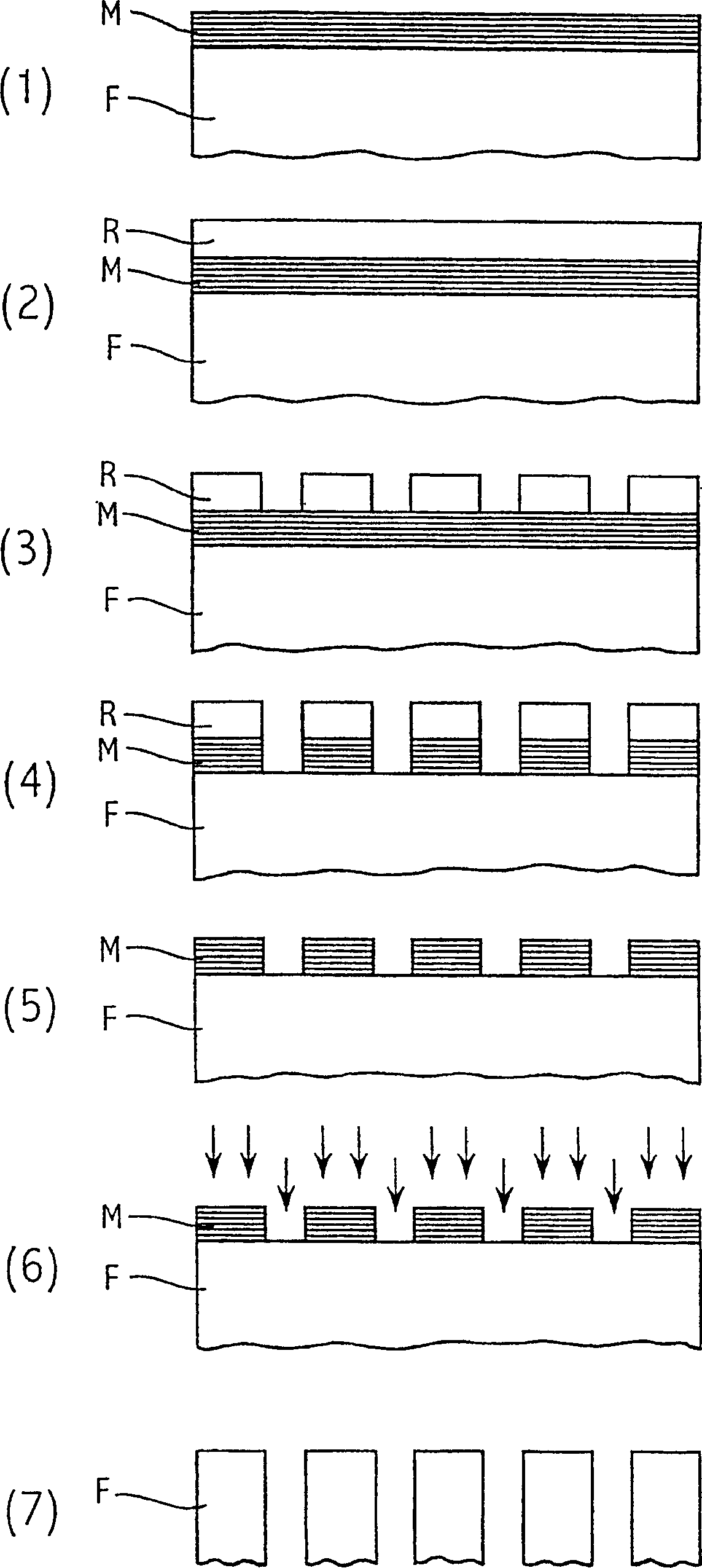

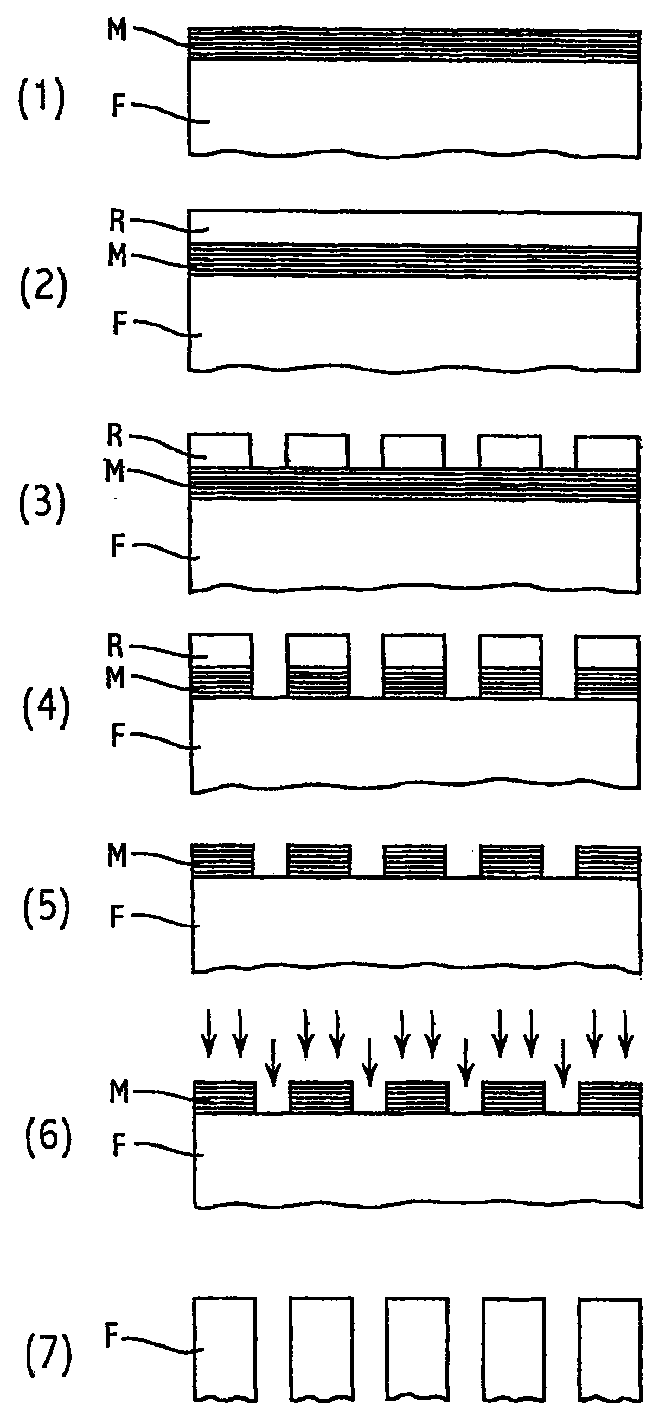

[0069] Implement the following steps to manufacture the grid ( figure 2 ):

[0070] (1) depositing a masking layer M consisting of an aluminum layer with a thickness of 1 micrometer on the foil F;

[0071] (2) Depositing a photosensitive resin layer R with a thickness of 1.2 microns on the masking layer;

[0072] (3) transfer the grid image to the resin R by interference method, and develop the resin by microelectronic technology;

[0073] (4) using...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com