Air electride

An air electrode and gas permeable layer technology, applied in the field of electrochemistry, can solve the problems of electrolyte leakage or volatilization, affecting battery performance, electrolyte carbonation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

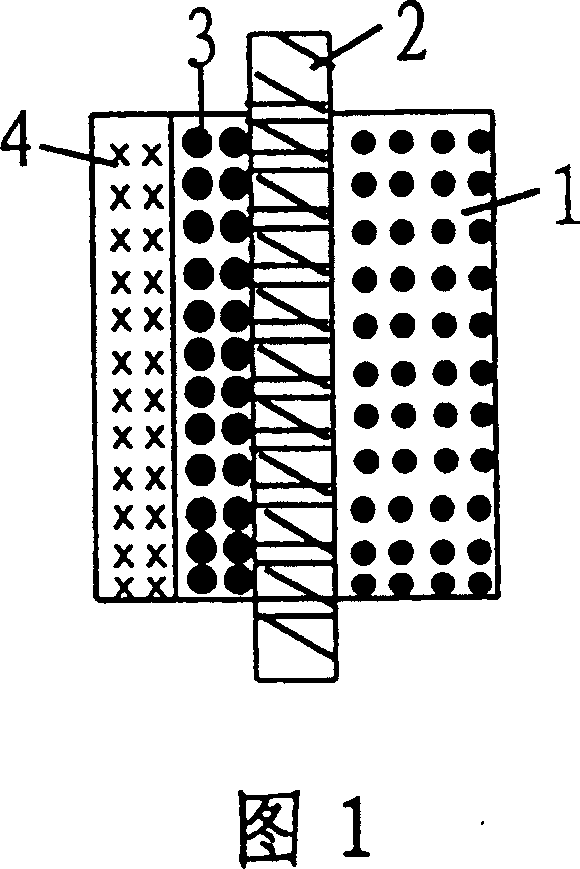

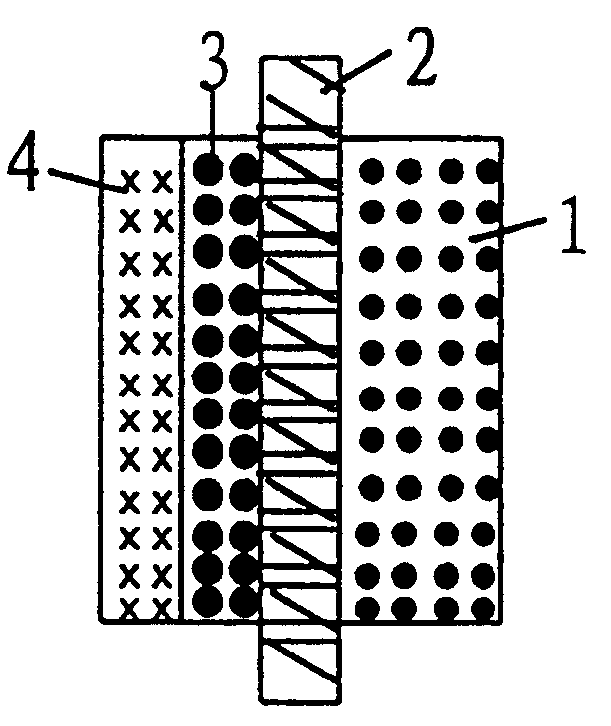

Embodiment 1

[0018] After mixing 200 grams of tetraphenylporphyrin cobalt and 1000 grams of activated carbon, heat at 700 ° C for 5 hours under the protection of inert nitrogen, then add 20% polytetrafluoroethylene binder and 10 kg of water and stir for 3 hours, at 10Mpa Rolled into a catalytic membrane with a thickness of about 0.1mm. The current collector uses a conductive nickel mesh. The water-repellent air-permeable layer is coated with a mixture of carbon black and 20% polytetrafluoroethylene on the uniaxially stretched nylon film and dried. The leak-proof sealing layer uses a Teflon film perpendicular to the stretching direction of the hydrophobic and air-permeable layer. Put glycerin-free cellophane in the sheeting film, put in the leak-proof sealing layer, water-repellent and breathable layer, conductive skeleton and catalytic membrane in sequence, then cover the catalytic membrane with cellophane, heat at 260°C and pressurize at 10Mpa. , cut into an area of 100cm 2 air elect...

Embodiment 2

[0020] After mixing 300 grams of manganese nitrate and 200 grams of activated carbon, heat at 900 ° C for 8 hours under the protection of inert nitrogen to obtain 280 grams of carbon powder containing manganese oxide, then add 250 grams of TritonX-100 binder and 5 kg of water and stir for 3 Hours, rolled into a catalytic membrane with a thickness of about 0.15mm at 8Mpa. The current collector uses a conductive nickel mesh. The hydrophobic air-permeable layer is a unidirectionally stretched Teflon film, and the leak-proof sealing layer uses a Teflon film perpendicular to the stretching direction of the hydrophobic air-permeable layer. Put glycerin-free cellophane in the sheeting film, put in the leak-proof sealing layer, water-repellent and air-permeable layer, conductive skeleton and catalytic membrane in turn, then cover the catalytic membrane with cellophane, heat at 260°C and pressurize at 8Mpa. , cut into an area of 100cm 2 air electrode. Polarization test was perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com