Solid thermal conductivity detector

A thermal conductivity detector and solid-state technology, applied in the field of analytical instruments, can solve problems such as application object restrictions, achieve the effects of simplifying the manufacturing process and requirements, improving temperature resistance, and broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

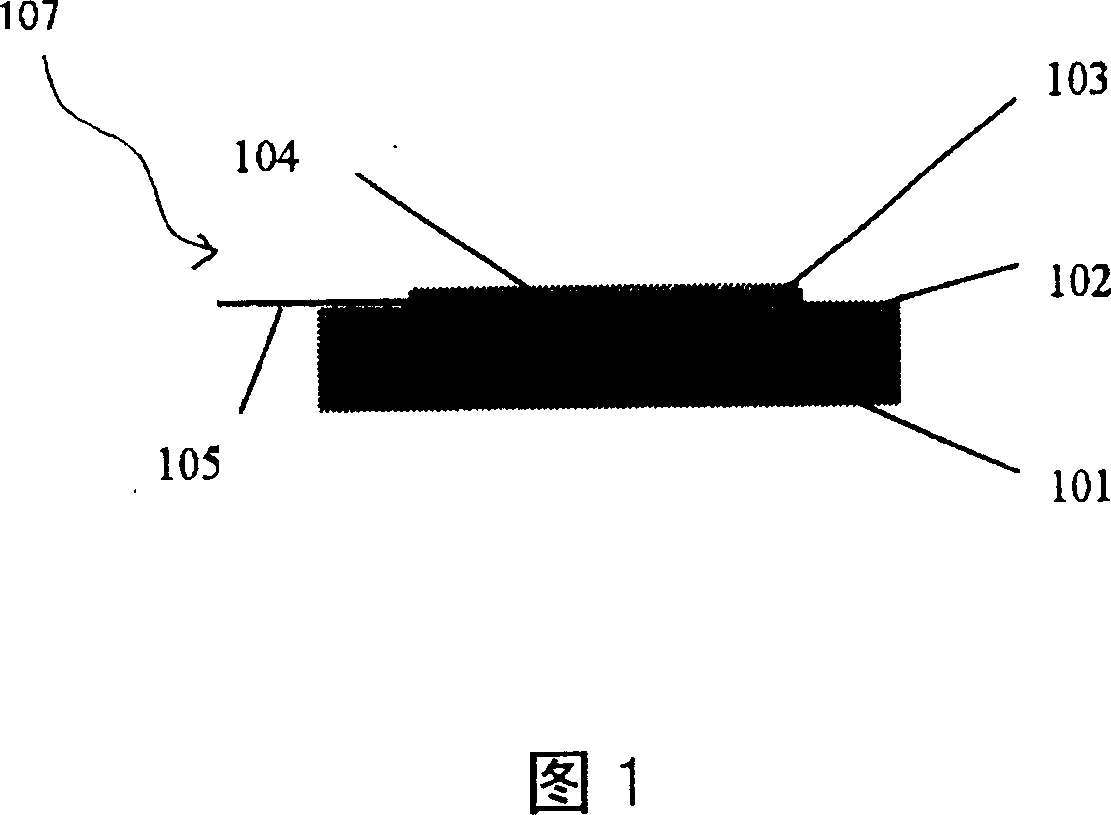

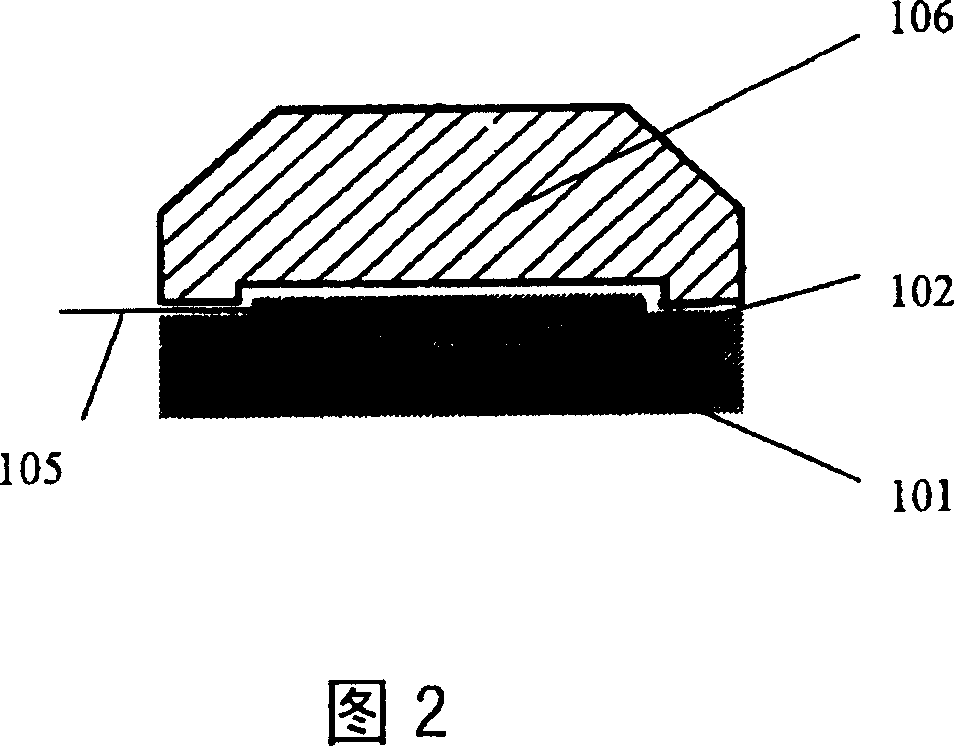

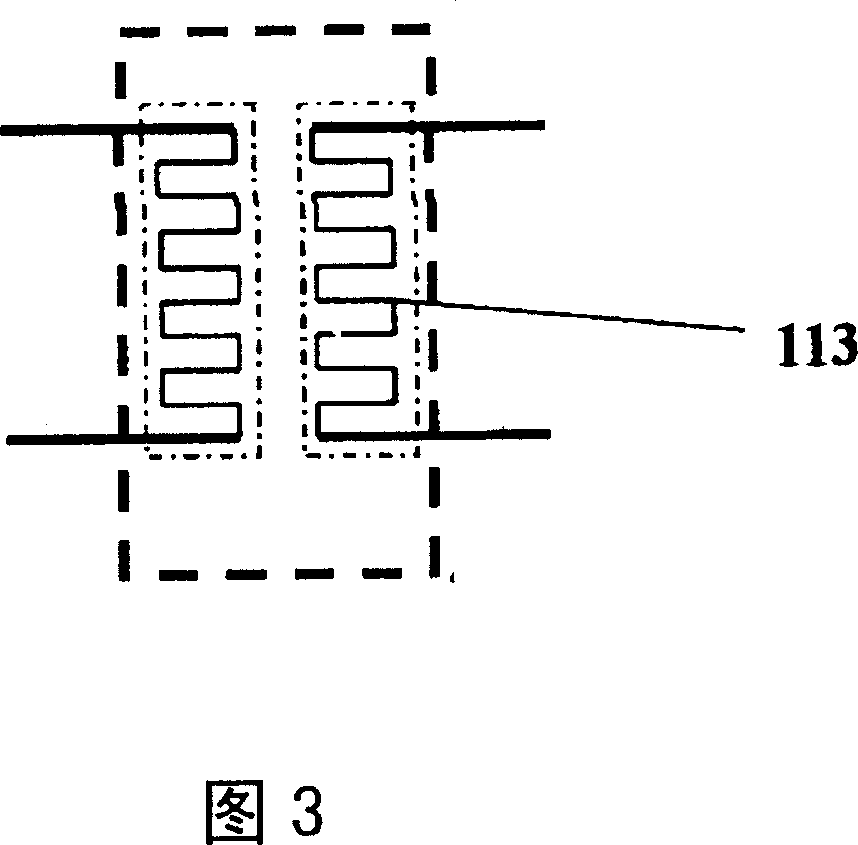

[0032] A solid-state thermal conductivity detector, a layer of 0.1mm glass-ceramic 102 is added on a 0.3mm ceramic substrate 101, and 1000 Å is sputtered on the surface of the glass-ceramic layer 102 The nickel layer is then etched to form two symmetrical comb electrodes 113 , and then passivated to form a passivation protection layer 104 . The lead-out line 105 is made by electric fusion welding of the silver wire and the lead-out area of the comb electrode 113 . The fabricated detector substrate 107 is embedded in the surface-passivated brass upper cover 106 to form two independent flow cells with gas inlet and outlet respectively. The distance between the comb electrode 113 and the upper cover 106 is 100 microns. The pair of comb electrodes 113 is connected to an external circuit to form a Wheatstone bridge.

[0033] Use two elastic quartz capillary columns with a length of 20 meters and an internal diameter of 0.53mm to be connected to the two inlets of the detector r...

Embodiment 2

[0035] A solid-state thermal conductivity detector, a layer of 0.2mm glass-ceramic 102 is added on a 0.5mm ceramic substrate 101, and the surface of the glass-ceramic layer 102 is sputtered for 2000 The nickel layer is then etched to form two symmetrical comb electrodes 113 , and a layer of 0.5 μm polyimide is coated on the surface of the comb electrodes 113 to form the protective layer 104 . Lead wires 105 are formed by electric fusion welding of silver wires and the lead area of the comb electrode 113 . The manufactured detector substrate 107 is embedded in the stainless steel upper cover 106 to form two independent flow cells, with gas inlet and outlet respectively. The distance between the comb electrode 113 and the upper cover 106 is 200 microns. The pair of comb electrodes 113 is connected to an external circuit to form a Wheatstone bridge.

[0036] Use two micro-packed stainless steel columns with a length of 2 meters, an inner diameter of 1mm, and a chromatographic...

Embodiment 3

[0038] A solid-state thermal conductivity detector, a layer of 0.1mm glass-ceramic 102 is added on a 0.3mm ceramic substrate 101, and 700°C is sputtered on the surface of the glass-ceramic layer 102 The platinum layer is then etched into four symmetrical comb electrodes 113 , and a layer of 0.5 μm polyimide is coated on the surface of the comb electrodes 113 to form the protective layer 104 . The lead-out wire 105 is made by electrofusion welding of the alloy wire and the lead-out area of the comb electrode 113 . The manufactured detector substrate 107 is embedded in the stainless steel upper cover 106 to form two independent flow cells, with gas inlet and outlet respectively. The distance between the comb electrode 113 and the upper cover 106 is 35 microns. These four comb electrodes 113 are connected to form a Wheatstone bridge.

[0039] Use two elastic quartz capillary columns with a length of 30 meters and an inner diameter of 0.25 mm to be connected to the two inlets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com