Wood method for pulping using cotton stalk, bush or brush

A technology for pulping and shrubs, applied in the field of pulp manufacturing, can solve the problems of ring compressive strength not meeting the requirements for producing corrugated base paper, rough pulp, poor paper bonding strength, etc., so as to shorten the soaking or steaming time and reduce the cooking temperature. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

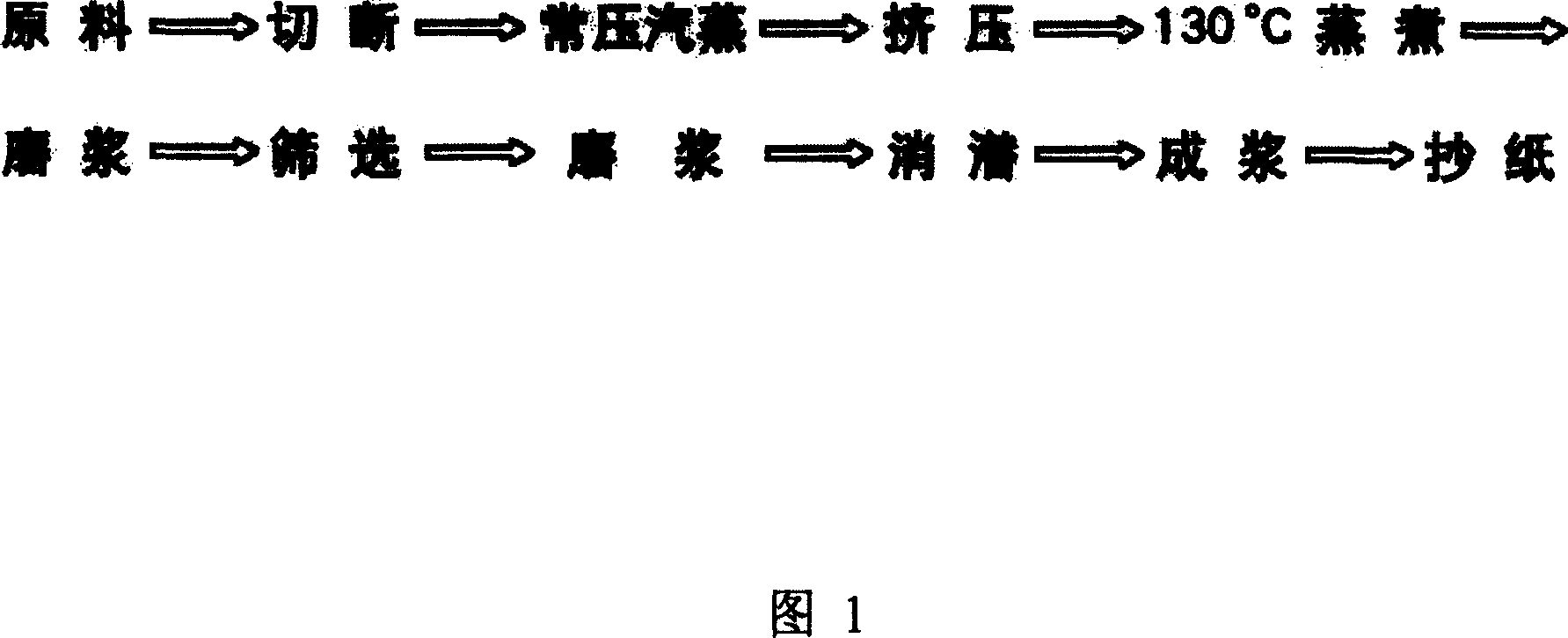

Embodiment 1

[0026] The raw material used in this embodiment is cotton rod. The raw materials are cut by a drum chipper, with a size of 3-4cm; the qualified raw materials are steamed for 10 minutes at normal pressure; The parts are made of stainless steel or chrome-plated cast steel. The structural compression ratio of the screw extruder is 1:2.7, and the material compression ratio is greater than 1:4. The cooking of the raw materials after extrusion is completed in a 15-liter cooking pot. Electric heating, automatic stirring. The cooking temperature is 130°C, the time is 30min (not including the heating time), the liquid ratio is 1:4.5, the amount of caustic soda is 5%, and AQ is 0.2%. The equipment used for refining raw materials after cooking is KRK300 high-concentration disc mill, with a disc diameter of 300mm, a motor power of 30kw, and a speed of 3000 rpm; the feeding method is adjustable speed screw feeding; Between the grinding area and the crushing area and on the outer edge of ...

Embodiment 2

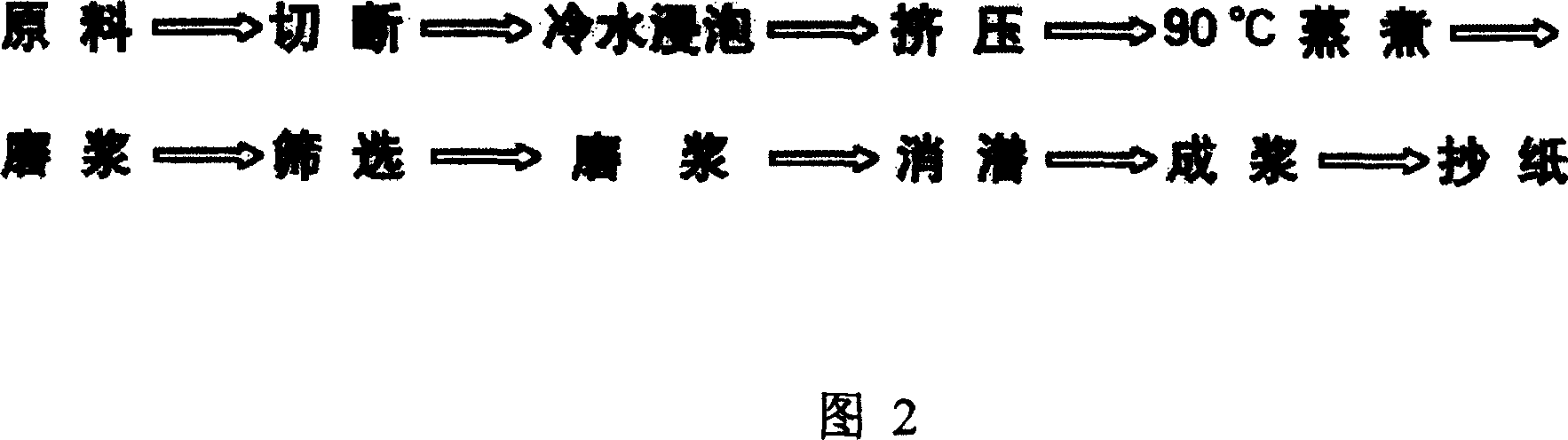

[0028] This embodiment also uses cotton stalk raw materials, wherein other steps are the same as in embodiment 1 except that the raw materials are soaked and boiled. Soaking: Qualified raw materials are soaked in cold water at a temperature of 20°C for 60 minutes. And the boiling temperature of raw material after rolling is 90 ℃, time 60min (not including heating time), liquid ratio 1: 4.5, caustic soda consumption 9%, AQ0.2%; Cooking container is the titanium plate impregnator volume of self-made 15 liters, constant temperature Water bath heating, manual stirring. The yield of pulp is 82.3%, and the weight of corrugated base paper made with 100% of this pulp is 108g / m 2 , fracture length 3.80km, ring pressure index 8.50N.m / g, tightness 0.52g / cm 3 , In addition to the length of the finished paper, all the indicators exceed the requirements of the national A-grade corrugated base paper.

[0029] It can be seen from Examples 1 and 2 that the pulping performance is superior, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com