Screw joint for steel pipe

A threaded joint, contact surface technology, applied in the direction of threaded connection, pipe/pipe joint/pipe fitting, drill pipe, etc., can solve problems such as difficulty in ensuring the performance of heat-resistant threaded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative Embodiment 1-4

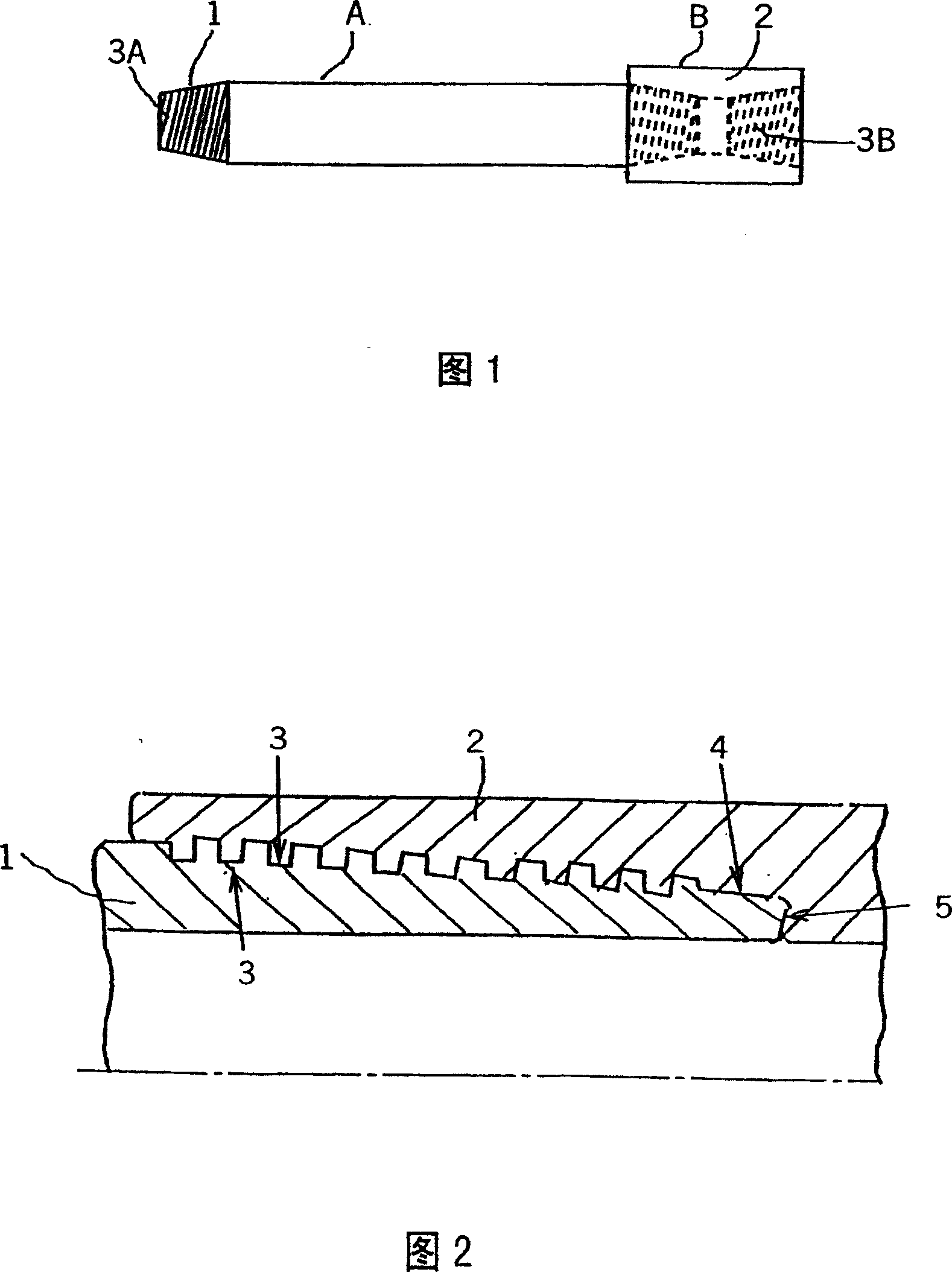

[0082] Made of a material selected from carbon steel A, Cr-Mo steel B, 13% Cr steel C, and high alloy steel D for steel pipes [outer diameter: 7 inches (178 mm), wall thickness: 0.408 inches (10.4 mm)] For threaded joints, the composition of each material is shown in Table 1 (D is the easiest to wear, and C, B, and A are hard to wear in turn), and the bolt surface and box sleeve surface of the joint are labeled as shown in Table 2 A surface treatment combination of 1-5 (surface pretreatment, optionally forming a solid lubricant coating), as described in each of the examples below. Table 2 shows the surface roughness Rmax (R) of the pretreatment and the thickness (t) of the undercoat (pretreatment coating) and the thickness (t) of the lubricant coating and the ratio of the lubricant powder and the resin (bonding agent). Mass ratio (M). In these embodiments, the contact surfaces of each of the pin and the casing are pretreated, but the solid lubricant coating is formed only on ...

Embodiment 1

[0105] Threaded joints were made of carbon steel of type A shown in Table 1, and the following surface treatments were applied to the threaded joints.

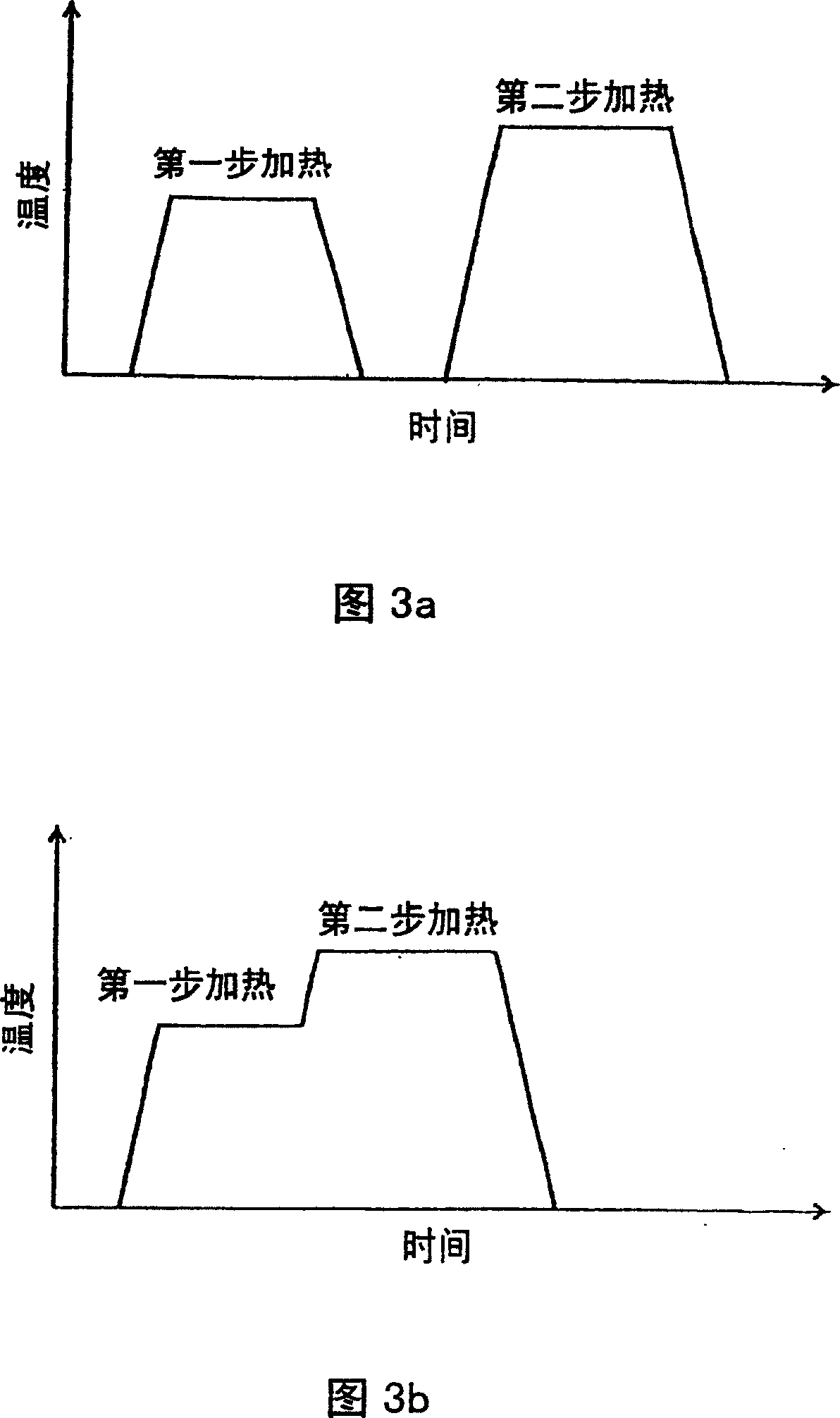

[0106] Sand blasting with No. 60 sand is used to pre-treat the surface of the box cover to make the surface roughness 31 μm. Then the box sleeve was preheated to 60° C., and a solid lubricant coating of polyamideimide resin containing molybdenum disulfide lubricant powder was formed on the contact surface with a thickness of 30 μm. In the solid lubricant coating containing molybdenum disulfide, the mass ratio of molybdenum disulfide to polyamide-imide resin is 4:1. The coating was dried with a first heating step at 100°C for 30 minutes, after cooling the coating to ambient temperature, a second heating step at 260°C for 30 minutes was performed.

[0107] The bolt surface is only machined and ground (surface roughness 3 μm).

[0108] The data shown in Table 2 are not indicated in the following examples.

Embodiment 2

[0110] Repeat the procedure of Example 1, except that the temperature of the preheating box sleeve before coating is changed from 60°C to 100°C, and the heating condition after coating is changed to: the first step of heating is to heat at 100°C for 30 minutes without cooling That is, the second step of heating is directly carried out, and the second step of heating is heating at 260° C. for 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com