Preparation of carbon nanometer pipe material and its equipment

A carbon nanotube and nanoscale technology, which is applied in the field of preparing carbon nanotube materials by means of plasma jet, can solve problems such as expensive raw materials, and achieve the effect of long operation period and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

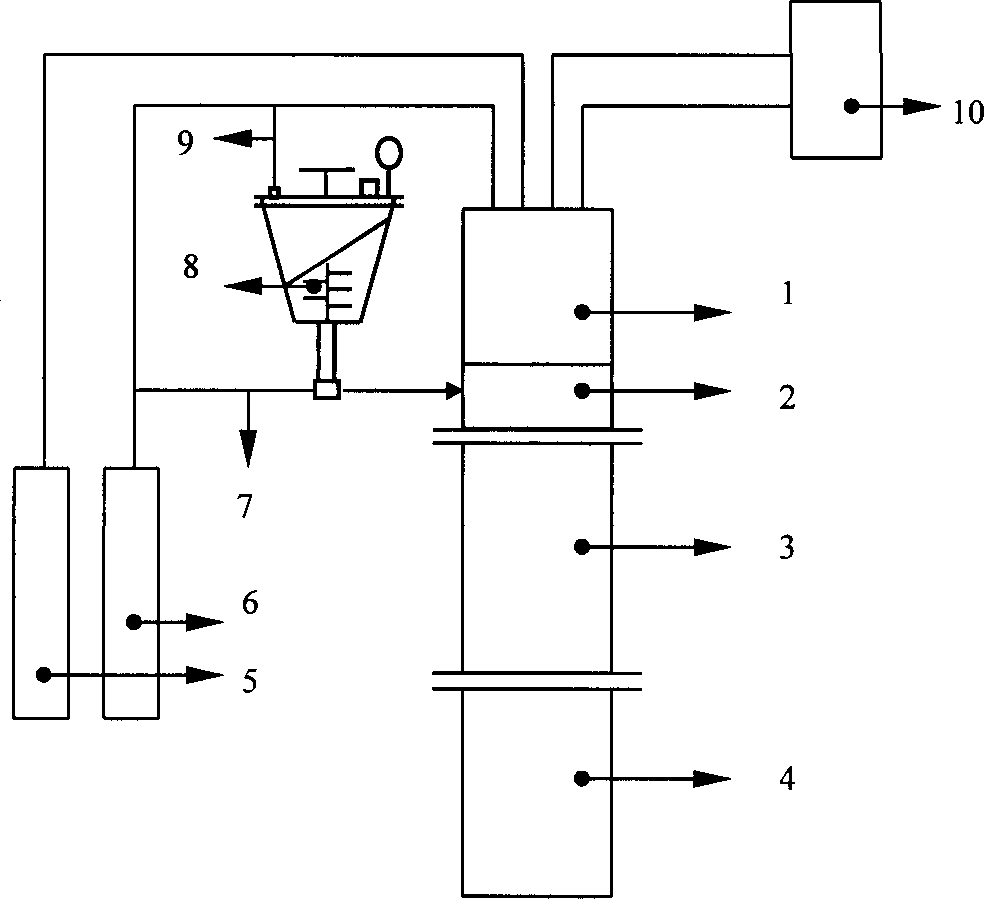

Method used

Image

Examples

Embodiment 1

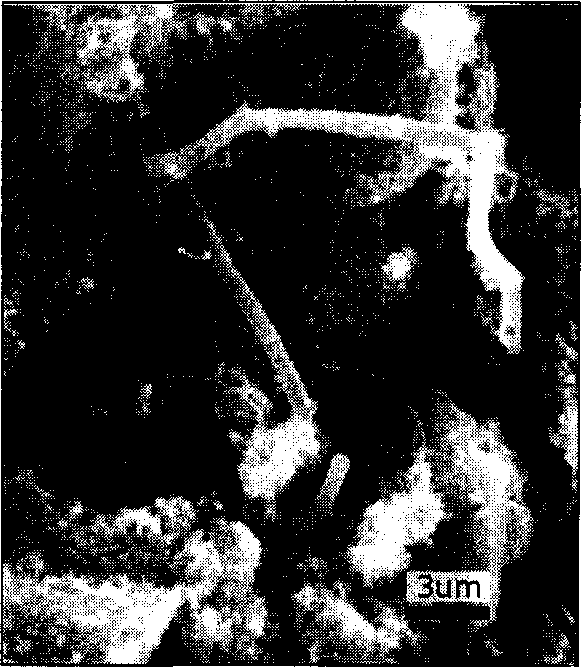

[0026] Shenfu coal is used as raw material, and the pulverized coal particle size is about 200 mesh. Use H 2 / Ar arc plasma jet, generator power is 40kW; hydrogen flow rate is 5.0m 3 / h, the argon gas flow rate is 1.8m 3 / h, the carrier gas flow rate is 1.2m 3 / h; The powder supply speed is 2.5g / s; After reacting for 5 minutes, a large amount of carbon nanotubes (see figure 2 ).

Embodiment 2

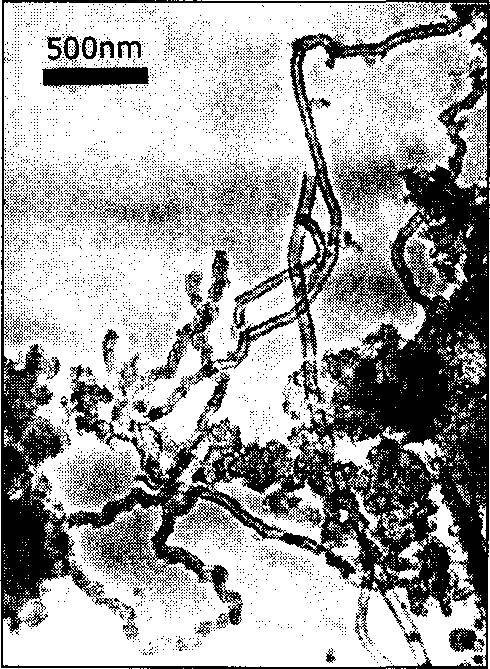

[0028] Baode coal is used as raw material, and the pulverized coal particle size is about 200 mesh, and 5% iron powder by weight of raw coal is added as a catalyst. Use H 2 / Ar arc plasma jet, generator power is 42kW; hydrogen flow rate is 5.2m 3 / h, the flow rate of argon gas is 2.2m 3 / h, the carrier gas is argon, and the flow rate is 1.7m 3 / h; the powder supply speed is 1.5g / s; after reacting for 8 minutes, a large number of carbon nanotubes can be observed by transmission electron microscope in the deposit on the inner wall of the reactor graphite. Carbon nanotubes have an outer diameter of 100 nm and an inner diameter of 30 nm (see image 3 ).

Embodiment 3

[0030] Baode coal is used as raw material, and the pulverized coal particle size is about 200 mesh, and cobalt powder with 7% of the raw coal weight is added as a catalyst. Use H 2 / Ar arc plasma jet, generator power is 40kW; hydrogen flow rate is 5.2m 3 / h, the flow rate of argon gas is 2.2m 3 / h, the carrier gas is argon, and the flow rate is 1.7m 3 / h; the powder supply speed is 3.0g / s; after 10 minutes of reaction, a carbon nanotube with a special structure can be observed in the sediment on the inner wall of the reactor graphite and in the pyrolysis residue in the collector through the transmission electron microscope Material, the graphite sheets of the tube wall of the carbon nanotubes are parallel to each other but inclined to the axial direction of the tube, and the angle between the graphite sheets and the axial direction is 25° to 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com