Method for preparing low hydroxy content optical-fiber precast rod by tubular CVD process

A chemical vapor deposition, optical fiber preform technology, applied in the field of optical fiber manufacturing, can solve the problems of increased OH absorption peak, difficult to achieve anhydrous peak fiber loss, failure to use and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

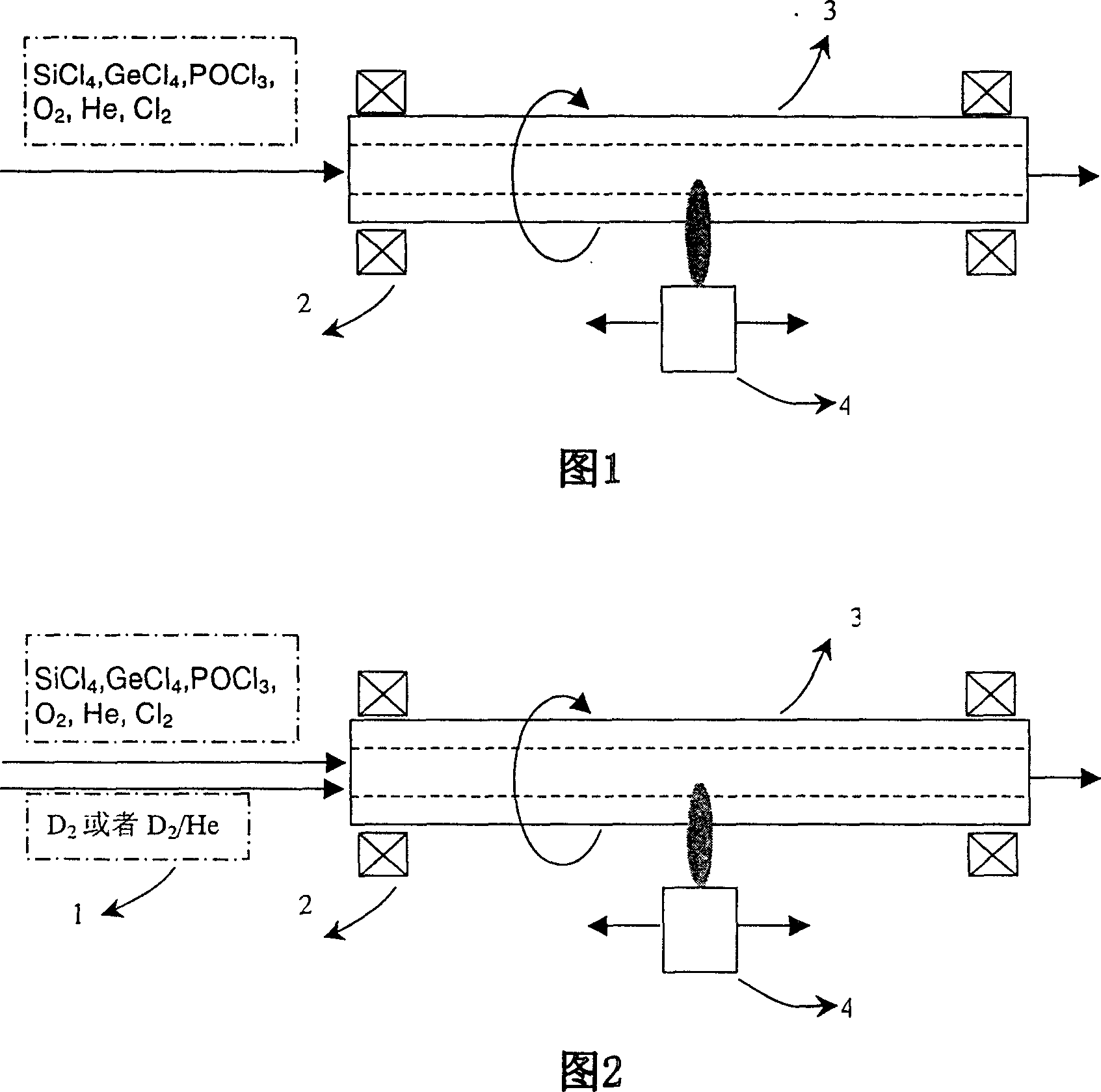

[0043] The method of preparing optical fiber preform by ordinary MCVD process is shown in Figure 1: First, deposit cladding and core layers from the inner wall to the center inside the pure silica substrate tube, and then place the deposited quartz glass at a high temperature of 2100-2300°C Melted into a solid mandrel. In order to increase the hydrogen-deuterium replacement process, it is necessary to improve the ordinary MCVD lathe and process to a certain extent.

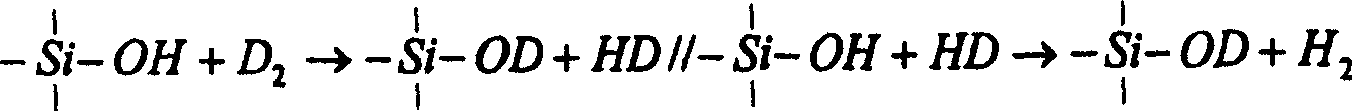

[0044] The present invention is a corresponding improvement on the traditional MCVD process, and its specific implementation is according to the process and device shown in Figure 2 .

[0045] A deuterium gas storage and purification system and delivery system 1 are added in front of the intake end of a common MCVD lathe. The purified deuterium gas enters the quartz tube on the MCVD lathe through its delivery system, and the flow of deuterium gas is controlled by an accurate mass flow meter. There are many ways ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com