Method for acquiring WS2/WO3 hollow microspheres by heat treatment of a hydrothermal precursor

A technology of hollow microspheres and precursors, which is applied in the direction of water pollutants, microsphere preparation, water/sewage treatment, etc., can solve the problems of danger in the vulcanization reduction process, affect product quality, and high-temperature vulcanization risks, and achieve uniform size, The effect of eliminating influencing factors and having few influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

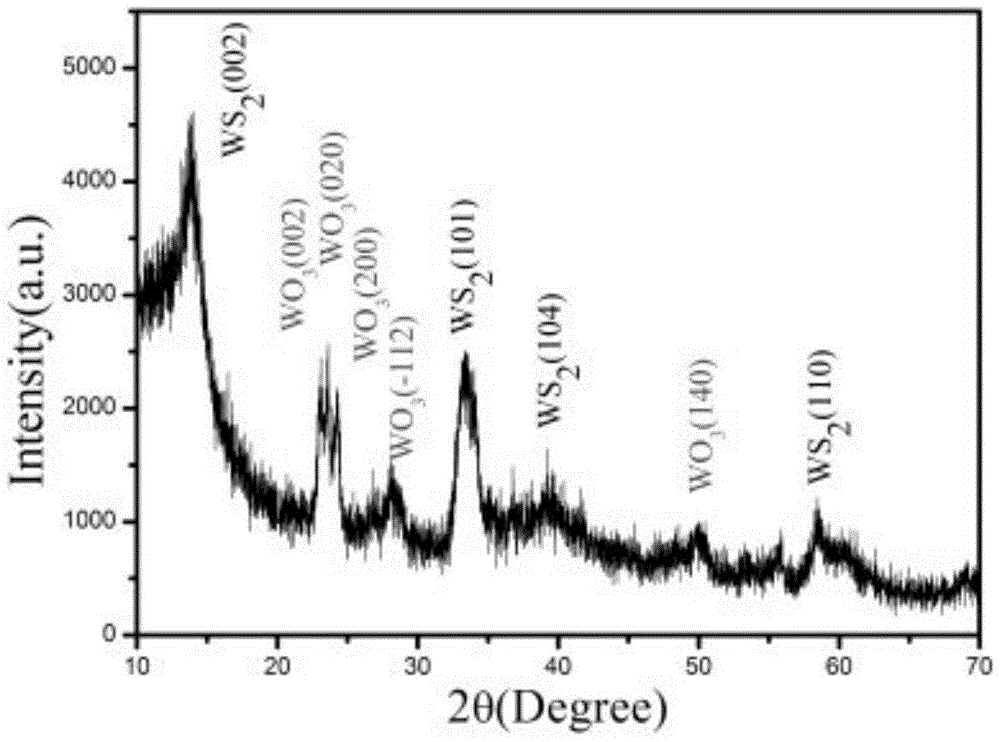

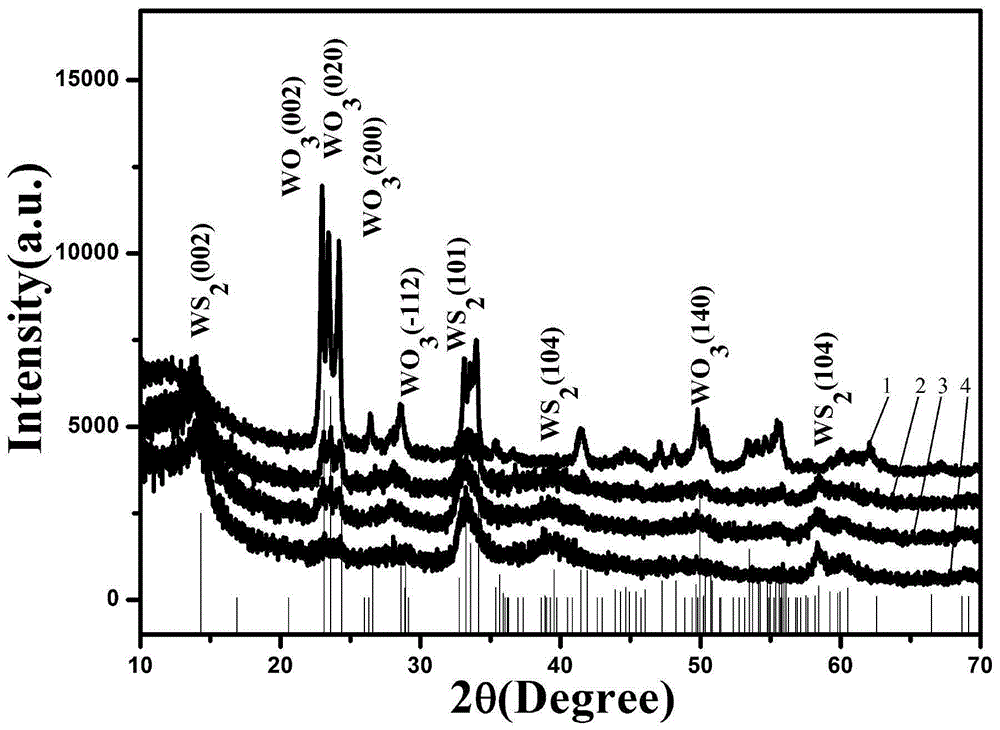

example 1

[0022] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 30min, during which O 2 10min.

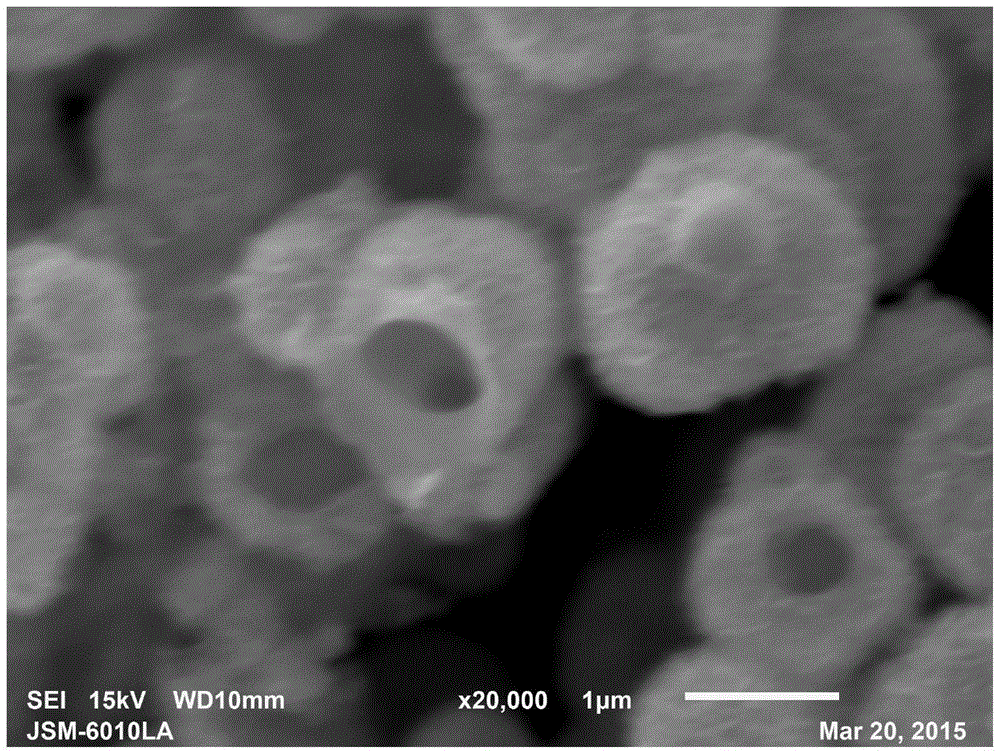

[0023] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: Add the reaction liquid into the inner tank of the reaction kettle in an amount of 2 / 3 of the volume of the inner tank of the reactor. In the high-pressure reactor, at 235°C, hydrothermally treat the reaction solution for 24 hours to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0024] The third step, heat treatment of the WS 2 / WO 3 Precursor: at 500°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 1h, the product WS 2 / WO 3 hollow microspheres.

example 2

[0026] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 25min, during which O 2 15min.

[0027] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: Add the reaction liquid into the inner tank of the reaction kettle in an amount of 2 / 3 of the volume of the inner tank of the reactor. In the high-pressure reactor, the reaction solution is hydrothermally treated for 30 hours at a temperature of 230°C to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0028] The third step, heat treatment of the WS 2 / WO 3 Precursor: at 470°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 1.5h, get the product WS 2 / WO 3 hollow microspheres.

example 3

[0030] The first step is to prepare the reaction solution: Weigh 1.19055g of tungsten hexachloride and 1.125g of thioacetamide respectively with an electronic balance, add them to 80mL of deionized water, and stir magnetically for 35min, during which O 2 5min.

[0031] The second step, hydrothermal preparation of WS 2 / WO 3 Precursor: add the reaction solution into the inner tank of the reaction kettle, the addition amount is 2 / 3 of the volume of the inner tank of the reaction kettle, and in the high-pressure reactor, at 240 ° C, hydrothermally treat the reaction solution for 20 hours to obtain a hollow Microspherical WS 2 / WO 3 Precursor.

[0032] The third step, heat treatment of the WS 2 / WO 3 Precursor: at a temperature of 520°C, in N 2 Heat treatment of the WS in a protective atmosphere 2 / WO 3 Precursor 0.5h, the product WS 2 / WO 3 hollow microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com