Alpha-cyano benzalcohol and alpha-cyano benzalcohol acetate mixture extraction and separation method

A technology of cyanobenzyl alcohol acetate and cyanobenzyl alcohol, which is applied in the field of extraction and separation of mixtures of α-cyanobenzyl alcohol and α-cyanobenzyl alcohol acetate, to achieve the effect of easy source, low price, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

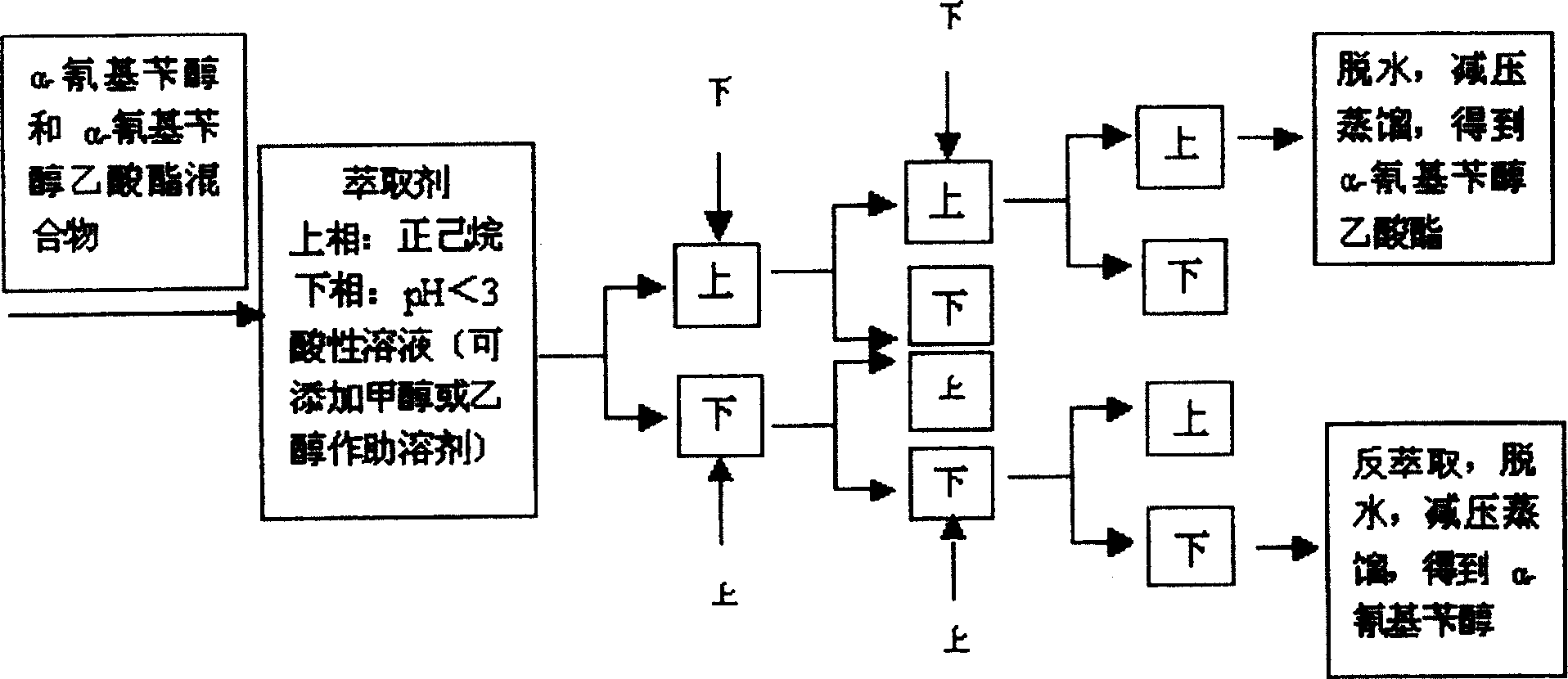

Image

Examples

Embodiment 1

[0012] The extractant is n-hexane and hydrochloric acid solution with pH=2, methanol is a co-solvent, the volume percentage of each component is 50%, 49% and 1% respectively, and the total volume is 2L. Add 32g of benzyl alcohol and racemic α-cyanobenzyl alcohol acetate to the extractant at 30°C, shake fully, let stand for 30rin, separate the upper and lower phases, and carry out secondary and tertiary extractions under the same conditions , the upper phase is dehydrated with anhydrous sodium sulfate and distilled under reduced pressure at 40°C to obtain α-cyanobenzyl alcohol acetate with a recovery rate of 85.73% and a purity of 95.48%; the lower phase is distilled under reduced pressure at 40°C When the volume remains constant, back-extract with an equal volume of ether, take the upper phase of the back-extraction, dehydrate with anhydrous sodium sulfate, and distill under reduced pressure at 40°C to obtain α-cyanobenzyl alcohol with a recovery rate of 89.12% and a purity of ...

Embodiment 2

[0014] The extractant is n-hexane and sulfuric acid solution with pH=1, ethanol is used as co-solvent, the volume percentage of each component is 50%, 40% and 10% respectively, the total volume is 400mL, and the racemic α-cyano group is added in equimolar ratio The mixture of benzyl alcohol acetate and racemic α-cyanobenzyl alcohol is 9.4g. After three stages of continuous extraction at 40°C, the upper phase is dehydrated with anhydrous sodium sulfate and distilled under reduced pressure at 50°C to obtain α-cyanobenzyl alcohol. Benzyl alcohol acetate, the recovery rate is 83.05%, and the purity is 92.37%; the lower phase is distilled under reduced pressure at 50°C until the volume remains constant, back extracted with an equal volume of ether, the upper phase of the back extraction is taken, and dehydrated with anhydrous sodium sulfate , Distilled under reduced pressure at 50°C to obtain α-cyanobenzyl alcohol with a recovery rate of 82.52% and a purity of 89.45%.

Embodiment 3

[0016] Extractant is the citric acid solution of normal hexane and pH=2, and methanol is cosolvent, and each component volume percent is respectively 50%, 45% and 5%, and total volume is 500mL, and adding molar ratio is 3: 1 (S 10.8g of the mixture of )-α-cyanobenzyl alcohol and (R)-α-cyanobenzyl alcohol acetate, after three stages of continuous extraction at 20°C, was processed according to the method of Example 1 to obtain (R) The recovery rate of -α-cyanobenzyl alcohol acetate was 83.89%, and the purity was 94.56%; the recovery rate of (S)-α-cyanobenzyl alcohol was 83.70%, and the purity was 90.12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com