Flush applied organic bio-fertilizer

A flush fertilization and organic technology, applied in the field of bio-organic compound flush fertilization, can solve the problems of no bio-organic flush fertilization, influence the development of green agriculture, and fertilizer fertilization restrictions, and achieve the effects of long fertilizer efficiency period, maintaining a virtuous cycle, and simple use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

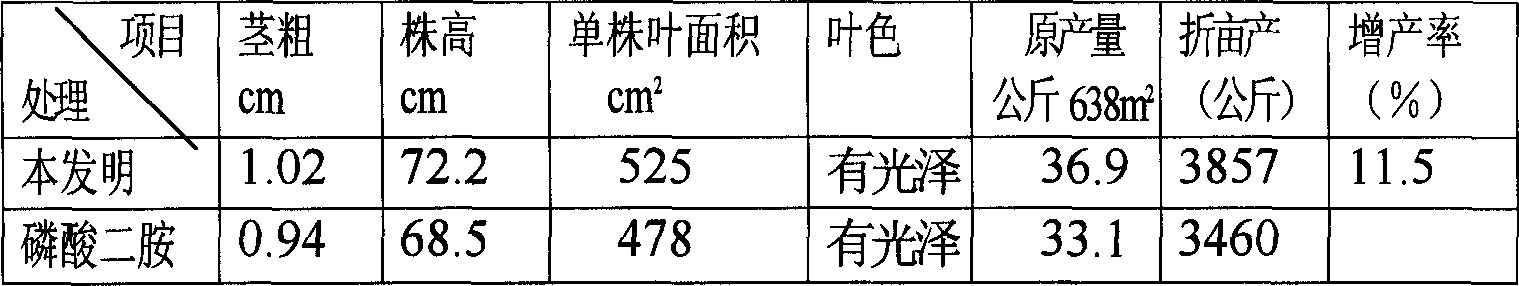

Image

Examples

Embodiment Construction

[0028] 1. Production of bacterial agents:

[0029] (1) First, activate the original strains of Bacillus silicate, transfer the original strains to a nitrogen-free medium, and cultivate them at a temperature of 26-30°C for 48 hours. Bacteria contamination, as shake flask seeds.

[0030] (2) Inoculate the activated strains in the shake flask culture medium, shake at 26-30°C (reciprocating shaker 110 times / min), cultivate for 24 hours, check for no miscellaneous bacteria under the microscope, and use it as a fermenter kind. Capacity: 300-1000ml triangular flask, seed quantity: one slant strain inoculates three bottles.

[0031](3) Submerged fermentation: Carry out first-level seed fermentation, the seeds cultivated by the above-mentioned shake flasks are inserted into 50 liter seed tanks according to the inoculum size of 5%, and fermented for 24 hours at 26-30° C. Bacterial contamination is transferred to secondary 500-liter seed tanks. After 24 hours of fermentation, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com