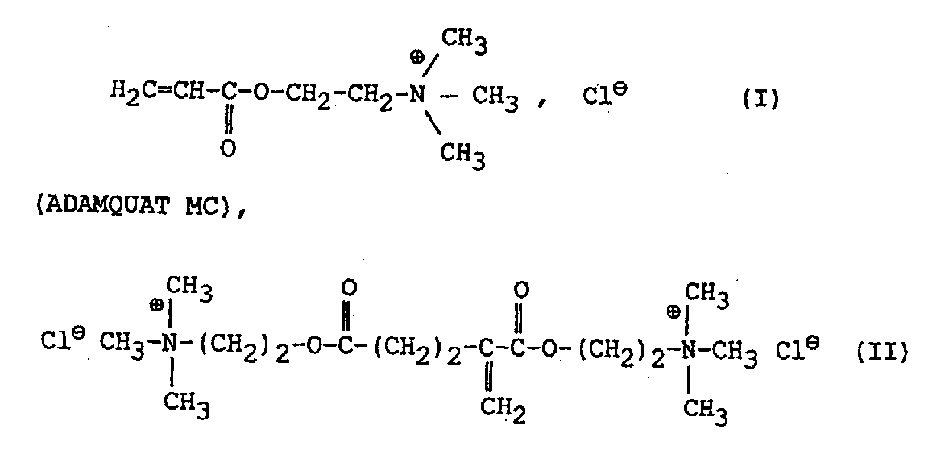

Method for raising molecular weight of acrylyl oxy-ethyl-trimethyl salmiac cation copolymer and relative copolymer

A technology of cationic copolymers and quaternary ammonium salt cations, which is applied in the field of increasing the molecular weight of acryloyloxyethyltrimethylammonium chloride cationic copolymers, and can solve problems such as linking impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Synthetic high-purity ADAMQUAT MC

[0039]In a jacketed, dedicated gas-liquid agitator (turbine with hollow shaft), valves with counterweights up to 10 bar, pressure relief tabs and downpipes for the addition of various reactants A 1 liter glass reactor designed to withstand pressure was charged with 429 g of ADAME. The reactor was closed and then pressurized to 1 bar with depleted air. Use stirring and heating.

[0040] When the temperature reaches 40°C (process temperature: 47°C), start adding CH at a flow rate of 159g / hr 3 Cl. When added to 15g CH 3 Cl, i.e. stoichiometric CH 3 At 10% of Cl, start adding water at a flow rate of 60g / hr while maintaining CH 3 The addition of Cl. During the whole reaction process H 2 O / CH 3 The flow ratio of Cl was kept constant at 0.37.

[0041] When all the water (approximately 1473 g) had been added, the reactor was returned to atmospheric pressure using the following procedure:

[0042] - Removal of excess C...

Embodiment 2

[0047] Embodiment 2: Synthetic ADAMQUAT MC of conventional purity

[0048] As in the operation of Example 1, just feed CH in 7 hours 3 Cl.

[0049] The reaction crude product (716 g) was analyzed by high-performance liquid chromatography (HPLC) to determine the content of ADAMQUAT MC dimer (general formula II), and the result was 3000 ppm.

Embodiment 3

[0050] Example 3: Manufacture of comparative cationic copolymers (gel method)

[0051] ADAMQUAT MC 80 produced according to Example 2 was polymerized according to the following gel method.

[0052] Polymerization was carried out as follows: 48 g of solid acrylamide were dissolved in 180 g of water. At this point 60 g of ADAMQUAT MC 80 was added to the solution. The mixture thus prepared is then placed in a Dewar type insulated container. Finally 0.005 g ammonium persulfate and 0.005 g sodium metabisulfite were added and polymerization started at ambient temperature. The gel obtained at the end of the polymerization is then ground and dried. The viscosity of the NaCl molar aqueous solution containing 0.1% of the cationic copolymer was measured with a Brookfield viscometer (DV-II type, rotating speed = 60 rpm, temperature = 20° C.), and the weight average molecular weight of the copolymer was estimated.

[0053] The viscosity of a NaCl molar solution containing 0.1% of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com