Composite high-voltage casing and its production process

A technology for high-voltage bushings and composite jackets, applied in products, conductors, insulators, etc., can solve the problems of poor mechanical and pollution resistance, unstable electrical performance, complex processing technology, etc., to improve pollution resistance, electrical and mechanical properties. Stable and reliable performance and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

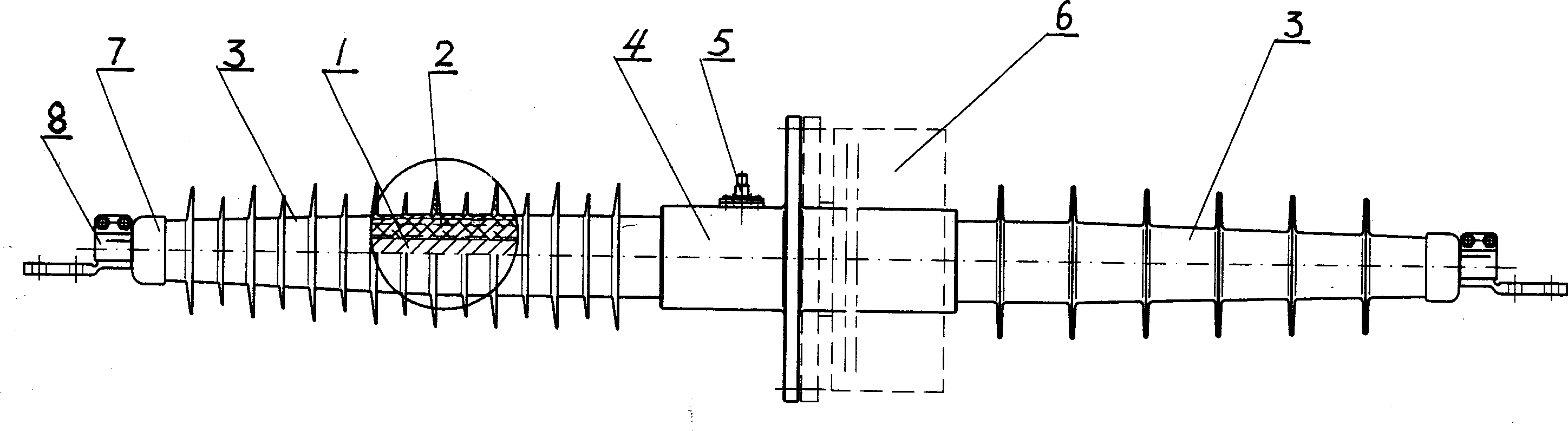

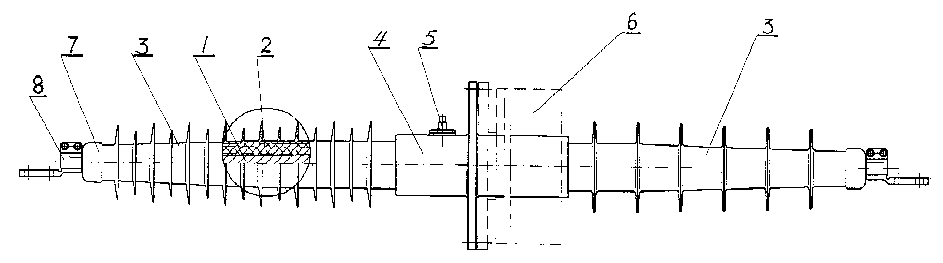

[0027] Such as figure 1 As shown: 1 is a conductive rod, which is made of copper rod (tube) or aluminum rod (tube). The conductive rod 1 and the main insulating layer 2 form a capacitor core (solid concentric cylinder series capacitor). The main insulating layer 2 can adopt the existing wet winding molding process during processing, and use the special equipment for winding epoxy wire or fiber cloth insulating tube (rod) to wrap semiconductor tape, glass wire dipped in epoxy resin, etc. Or the glass fiber braids are wound and shaped at intervals according to the sinusoidal curve to form a tightly bonded main insulating layer 2 on the conductive rod 1 .

[0028] The specific operation of manufacturing capacitor core is as follows:

[0029] a. First, fix the conductive rod 1 on the winding frame, start the winding machine and start the heating device at the same time, and adjust the heating temperature to 120°C. In order to make the winding effect better, the conductive rod can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com