New technology for anti-electrostatic flame-retarded glass fibre reinforced plastics compound pipe

A glass fiber reinforced plastic and composite pipe technology, which is used in the processing of fireproof pipes and explosion-proof fields, can solve the problems of lack of ideal process and structure scheme, flashover, and affecting the popularization and application of glass fiber reinforced plastic composite pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

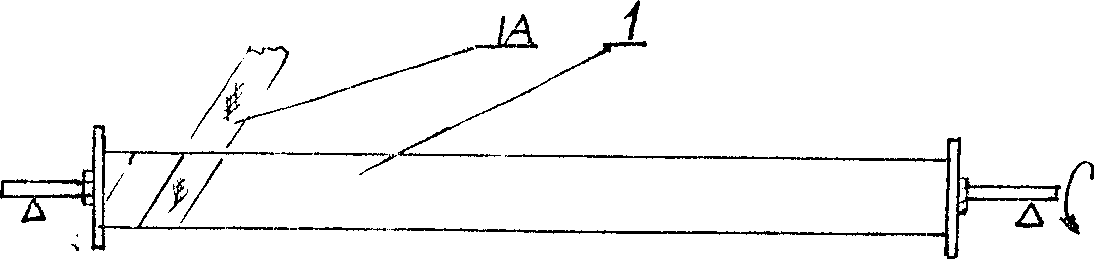

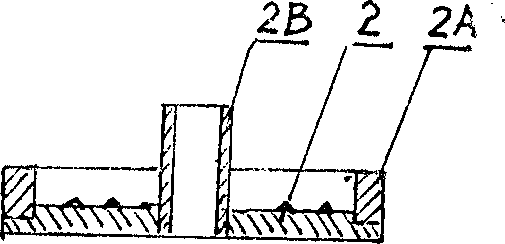

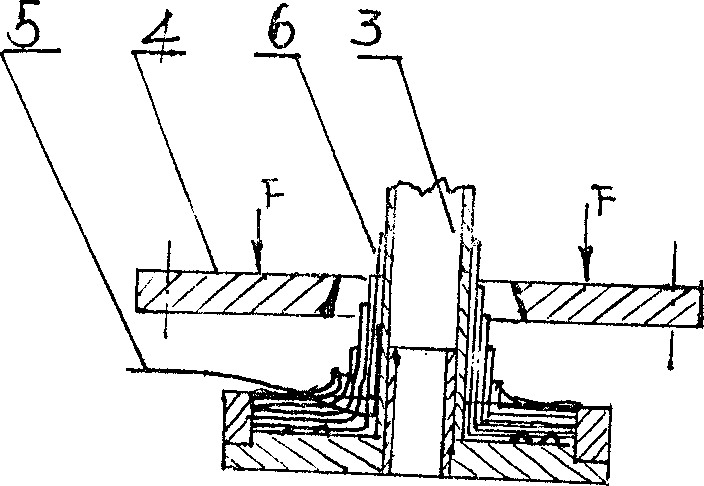

[0017] Among the components, No. 1 is commercial resin glue, which can be unsaturated polyester resin, phenolic resin, or epoxy resin. No. 2 is talcum powder, No. 3 is graphite powder, and No. 4 is active antistatic agent. Specifically, it can be used Shandong Jinan Chemical Research Institute publicly sells products with the name of "glass fiber high-efficiency antistatic agent", or other similar market products. No. 5 is a flame retardant, specifically, any one of aluminum hydroxide hydrate, antimony paste, and lithium bromide can be used. No. 6 is cast stone powder, No. 7 is quartz powder, and No. 8 is thixotropic agent. Specifically, white carbon black or glass beads can be used. No. 9 is curing agent. Specifically, ketone peroxide, ethyl ketone, and methyl peroxide can be used. Acyl, any one of cyclohexanone peroxide. No. 10 is an accelerator, specifically cobalt naphthenate or methylaniline can be used, and No. 11 is a diluent, specifically any one of acetone, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com