Anti-adversity cotton ball protection type foliage spraying agent for cotton

A foliar spraying and spraying agent technology, which is applied in the application, biocide, animal repellent, etc., can solve the problems of short storage period, low quality, poor application effect, etc., to ensure safe production and stable performance , a significant effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

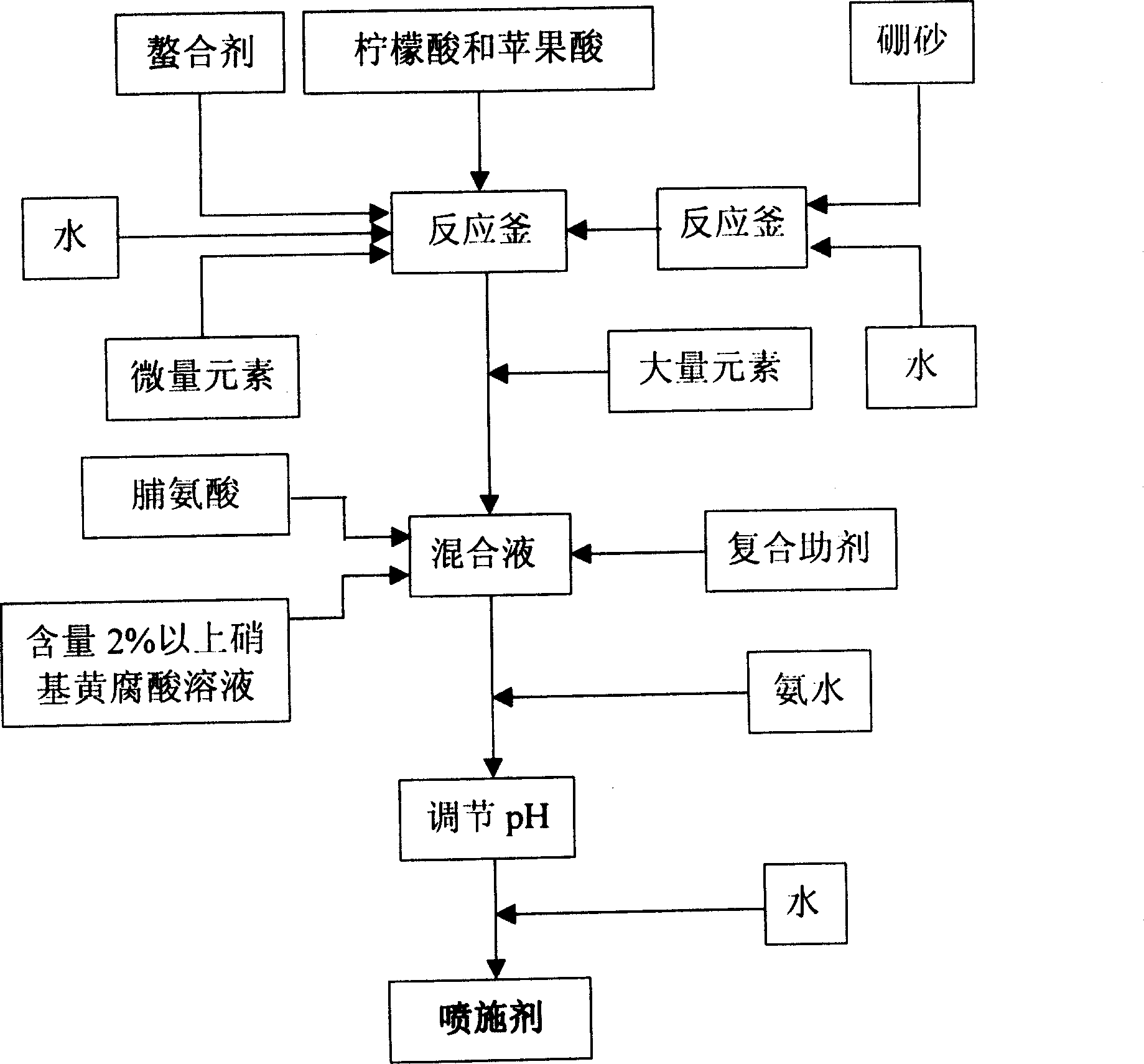

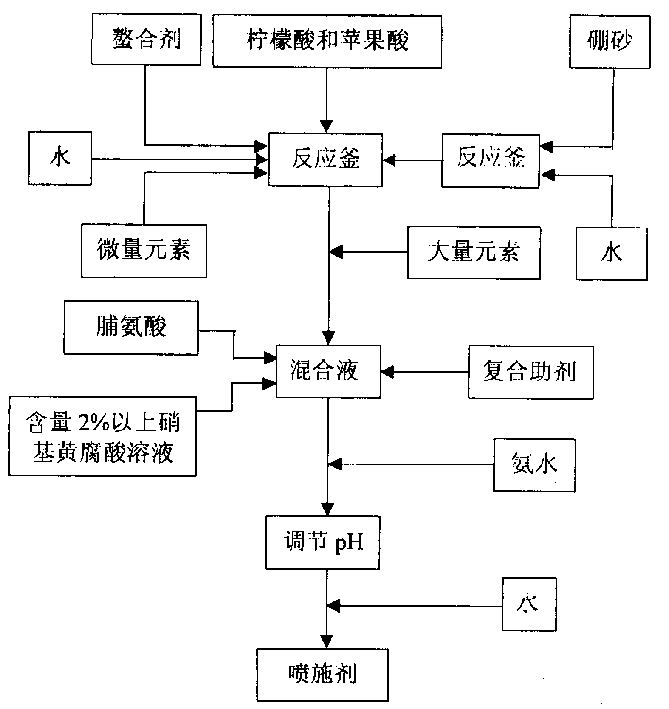

Method used

Image

Examples

Embodiment 1

[0009] Embodiment 1 (1) the preparation of compound auxiliary agent. Mix 100 parts of triethanolamine and 80 parts of glycerin, add 20 parts of OP-10 into the mixture, stir, and prepare compound additives. (2) Weigh 100Kg disodium EDTA and dissolve it in 250L of water at 70-80°C, and dissolve it in FeSO in turn 4 ·7H 2 O 80Kg, MnCl 2 ·6H 2 O 100Kg, CuSO 4 ·5H 2 O 10Kg, ZnSO 4 ·7H 2 O 100Kg; citric acid 150Kg, polyphosphoric acid 50Kg, prepared as solution A. (3) Dissolve 50Kg of borax in 100L of water at 70-80°C, then add liquid A, stir, and then add MgCl in turn 2 ·4H2O 50Kg, urea 100Kg, KNO 3 100Kg to obtain liquid B. (4) Add 50L content of 2-4% nitrofulvic acid solution 50-100L / m3, proline 20Kg, and compound auxiliary agent 50L in B liquid, and adjust the pH value to 3-3.5 with ammonia water, then water Set the volume to 1000L. The liquid is a special foliar spray for stress-resistant boll-preserving cotton.

Embodiment 2

[0010] Embodiment 2 (1) the preparation of compound auxiliary agent. Mix 120 parts of triethanolamine and 40 parts of glycerin, add 40 parts of OP-10 into the mixture, stir, and prepare compound additives. (2) Weigh 50Kg disodium EDTA and dissolve it in 250L water at 70-80°C, and dissolve it in FeSO in turn 4 ·7H 2 O 120Kg, MnCl 2 ·6H 2 O 50Kg, CuSO 4 ·5H 2 O 5Kg, ZnSO 4 ·7H 2 O 120Kg; citric acid 100Kg, malic acid 20Kg, polyphosphoric acid 30Kg, prepared as solution A. (3) Dissolve 30Kg of borax in 100L of water at 70-80°C, then add liquid A, stir, and then add MgCl in turn 2 4H 2 O80Kg, urea 80Kg, KNO 3 80Kg, obtain B liquid. (4) Add 80L of nitrofulvic acid solution with a content of 2-4% and 50L of compound additives to liquid B, adjust the pH value to 3-3.5 with ammonia water, and then dilute to 1000L with water. The liquid is a special foliar spray for stress-resistant boll-preserving cotton.

Embodiment 3

[0011] Embodiment 3 (1) the preparation of compound auxiliary agent. Mix 40 parts of triethanolamine and 60 parts of glycerin, add 100 parts of OP-10 into the mixture, stir, and prepare compound additives. (2) Weigh 80Kg disodium EDTA and dissolve it in 250L water at 70-80°C, and dissolve it in FeSO in turn 4 ·7H 2 O 50Kg, MnCl 2 ·6H 2 O 150Kg, CuSO 4 ·5H 2 O 10Kg, ZnSO 4 ·7H 2 O 50Kg; malic acid 70Kg, polyphosphoric acid 30Kg, prepared as solution A. (3) Dissolve 60Kg of borax in 150L of water at 70-80°C, then add liquid A, stir, and then add MgCl in turn 2 4H 2 O30Kg, urea 180Kg, KNO 3 50Kg to obtain liquid B. (4) Add 30Kg of proline and 50L of compound additives to liquid B, adjust the pH value to 3-3.5 with ammonia water, and then adjust the volume to 1000L with water. The liquid is a special foliar spray for stress-resistant boll-preserving cotton. Embodiment 4 (1) the preparation of compound auxiliary agent. Mix 100 parts of triethanolamine and 60 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com