Composite titanium-base film photoelectrode and its making process

A composite photoelectrode technology, which is applied in chemical instruments and methods, catalyst activation/preparation, circuits, etc., can solve the problems of unsatisfactory photocatalysis and conversion performance, large band gap, and low solar energy utilization rate. Achieve the effects of easy adjustment of doping concentration, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1:8.5ml,11.7mlA;272、204、136、6.8、0 3 to 11.7ml、0.68ml、0.9ml,217 7 B;B1ml/ to A,10;1,600mm/h,10500℃10, 1 , to 1 , to 0.1-0.15, to ;600℃30,,,。 Embodiment 2

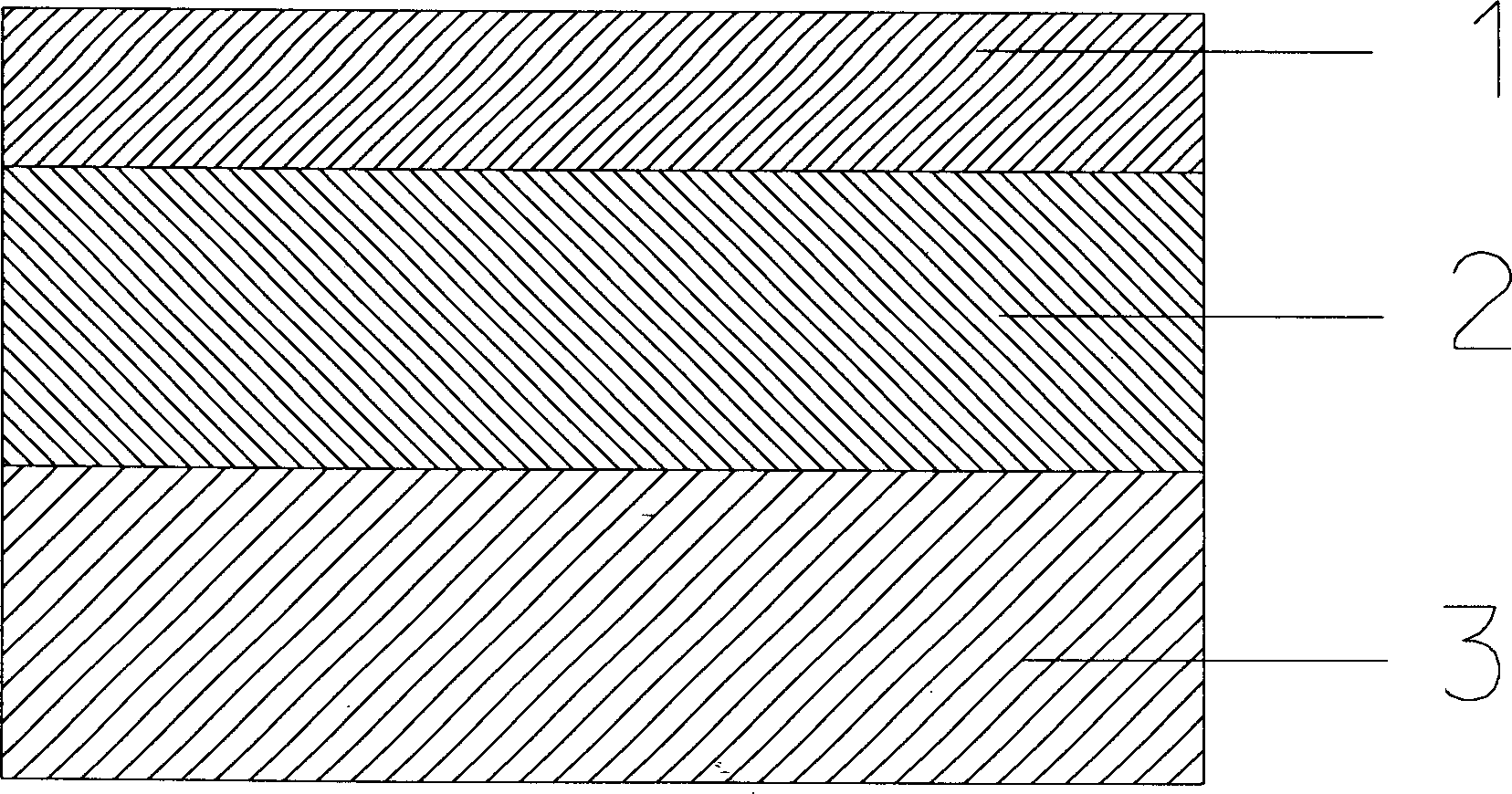

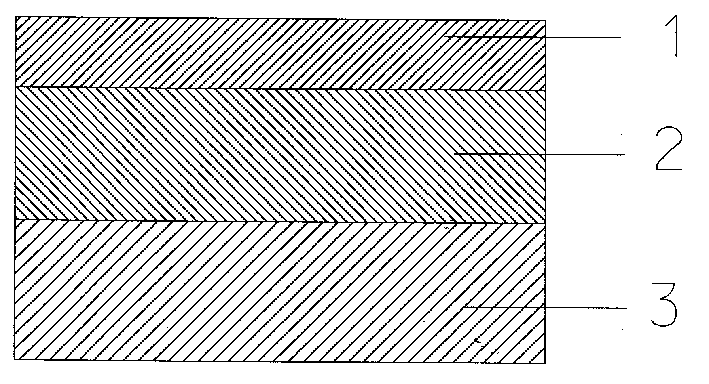

[0015] Example 1: Take 8.5ml of titanate and 11.7ml of ethanol and mix and stir in a flask to obtain liquid A; ml, 0.68ml of hydrochloric acid, and 0.9ml of water, add 217 mg of cobalt sulfate heptahydrate at the same time to obtain series B liquids; respectively add series B liquids dropwise to A liquid at a rate of 1 ml / min, and stir The sol is obtained in 10 minutes; the pre-treated titanium sheet is immersed in the sol with the highest ruthenium content for 1 minute, pulled at a rate of 600mm / h, dried in the air for 10 minutes and then calcined at 500°C for 10 minutes to complete a coating film. Repeat the coating to complete the doping of a series of sols from thick to thin, and make the thickness of the film layer reach 0.1-0.15 microns, so as to complete the coating process of metal ruthenium ion content from thick to thin; finally in the undoped sol The intermediate coating film was calcined at 600°C for 30 minutes, cooled naturally, spot-welded wires on the back, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com