Preparation method of nano catalyst for low-temp. fuel cell

A nano-catalyst and fuel cell technology, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of long preparation time, inability to form alloys, and the equalization of various components, and achieve increased preparation time and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

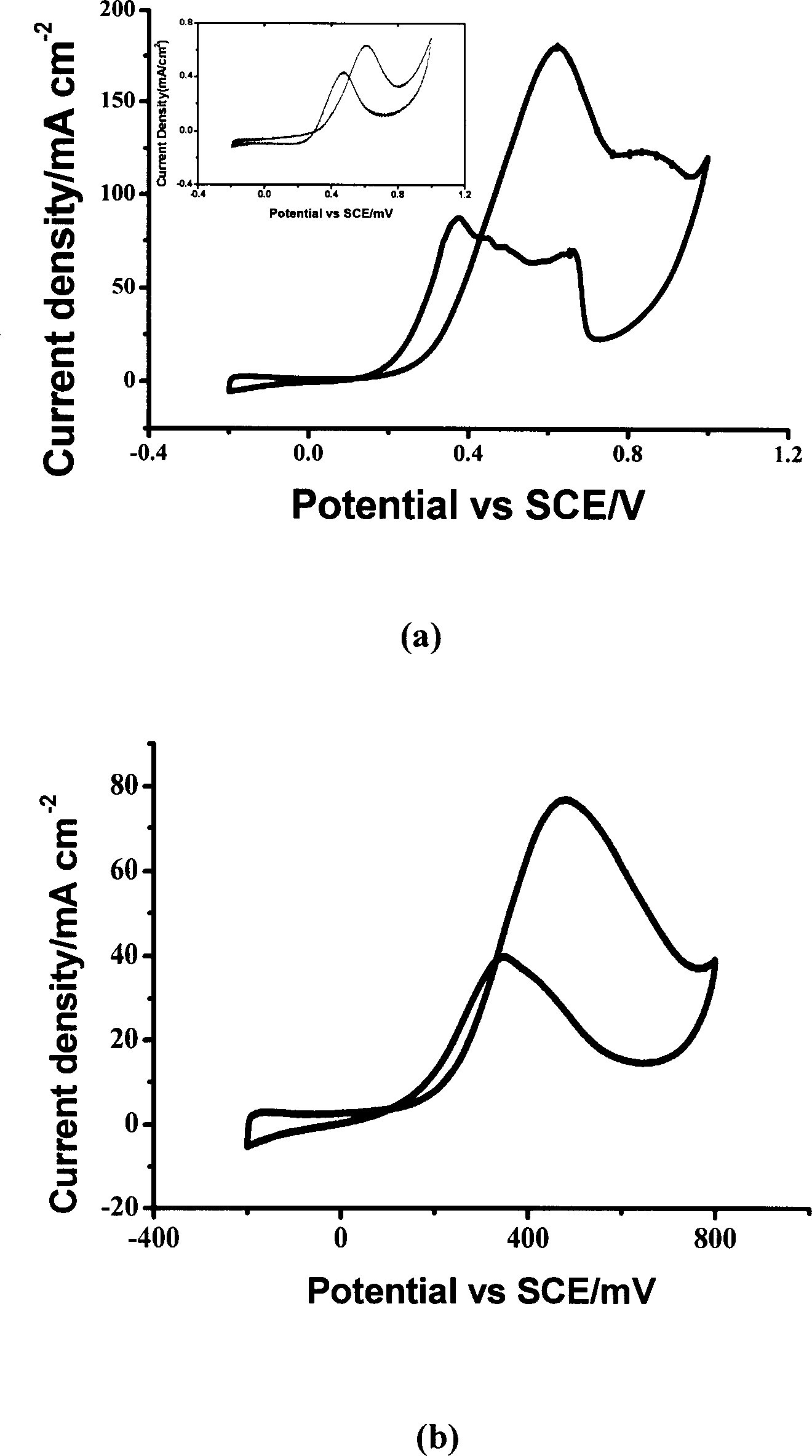

Image

Examples

Embodiment 1

[0020] Get 0.5g carbon black (Vulcan XC-72, the U.S. Cabot Company produces) and place in 100ml reactor, add 4ml acetone solution, ultrasonically stir for 5 minutes, drop into platinum content and be the chloroplatinic acid solution 11.1ml of 30mg / ml, then Ultrasonic homogenization until the sample becomes a paste, the beaker containing the sample is transferred to a large glass container with a volume of 250ml using carbon black as a microwave sensitive material, and the above reactor is placed in a modified household microwave oven (frequency is 2.45GHz, The output power is 850W). The intermittent microwave heating program is used to first induce the conversion of chloroplatinic acid into a water-insoluble intermediate product, and the heating program is controlled as microwave heating for 15 seconds--stop for 40 seconds--heat for 10 seconds--stop for 60 seconds--heat for 10 seconds--stop 75 seconds-heating for 10 seconds-stop for 120 seconds. The reactor was removed, coole...

Embodiment 2

[0022] Get 0.5g of carbon black (Vulcan XC-72, produced by U.S. Cabot Company) and place it in a 100ml reactor, add 4ml of acetone solution, stir ultrasonically for 5 minutes, drip 25ml of chloroplatinic acid solution with a platinum content of 30mg / ml, and then ultrasonically Mix until the sample becomes a paste, add excess formic acid solution dropwise under ultrasonic stirring, and adjust the pH value to 9 with ammonia water. Then the beaker containing the pasty sample was transferred to a large glass container with a volume of 250ml using carbon black as a microwave sensitive material, and the above reactor was placed in a modified household microwave oven (frequency 2.45GHz, output power 850W). The intermittent microwave heating program is used to first induce the reduction of chloroplatinic acid to metal platinum, and the heating program is controlled as microwave heating for 15 seconds-stop for 40 seconds-heat for 10 seconds-stop for 60 seconds-heat for 10 seconds-stop f...

Embodiment 3

[0024] Take 0.5g of carbon black, add 4ml of acetone / water solution (acetone, water volume ratio: 1:5) and add dropwise 4.2ml of chloroplatinic acid aqueous solution with a platinum content of 30mg / ml and 12.5ml of a tungsten content of 10mg / m1 under ultrasonic stirring WO 3 Aqueous solution (prepared by reacting tungsten powder with excess hydrogen peroxide) to form a mixed solution. The operation method of microwave solidification and microwave-assisted reduction is the same as that of Example 1. PtWO with a loading of 40% and a platinum-tungsten atomic ratio of 1:1 3 / C Catalyst. XRD results show that tungsten trioxide exists in an amorphous state, and the particles of platinum are smaller than 4nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com