Process for purifying swainsonine in Feng grass

A swainsonine and process technology, applied in the field of natural product chemistry research, can solve the problems of inability to mass production, low extraction rate and the like, and achieve the effects of low extraction cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

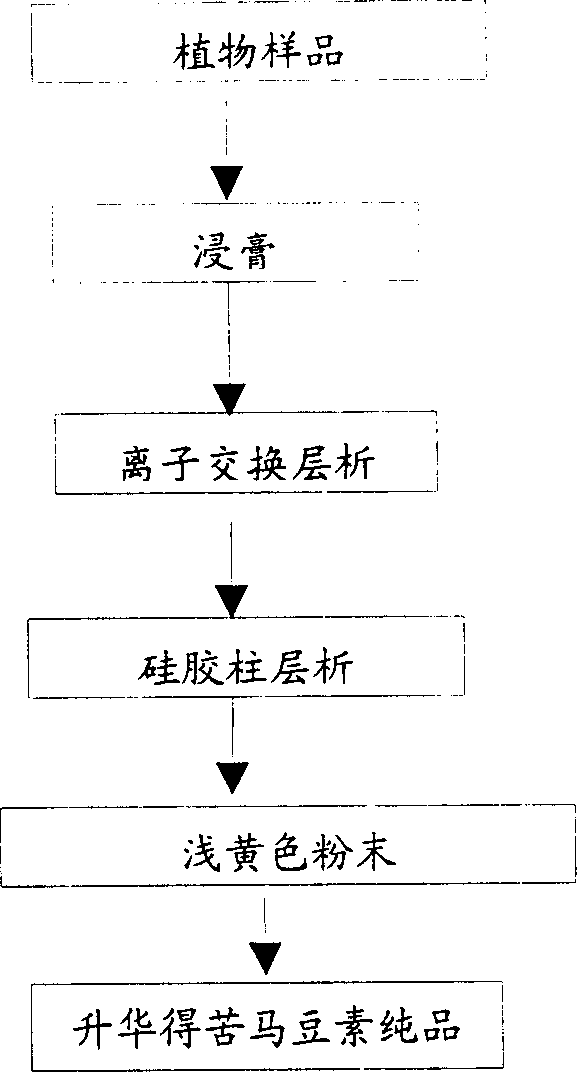

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the extraction of swainsonine in Oxytropis gansu

[0031] The first step, extract extraction stage: Gansu Oxytropis hay powder 5kg, cold immersion extraction with 30 liters of industrial methanol 4 times, each cold immersion for 7 days, filtering, merging methanol liquid, recovering methanol under reduced pressure to obtain 680g of total extract, The paste yield was 13.6%.

[0032] The second step, crude alkaloid extraction stage: 680g total extract was ground and dissolved repeatedly with 6800mL 1N hydrochloric acid, and filtered until the last acid water improved bismuth iodide potassium test showed a negative reaction, and the acid water was combined. The obtained acidic aqueous solution was adjusted to a pH of 4-5 with concentrated ammonia water, passed through a hydrogen-type cation exchange resin column, first eluted with 100 times the amount of sample-loaded deionized water until colorless, and then eluted with 20 times the amount of 1N ammonia wate...

Embodiment 2

[0036] Embodiment 2: Extraction of swainsonine in Oxytropis japonica

[0037] The first stage of extraction of extract: 11.5kg of Oxytropis chrysantha hay powder, cold soaked with 70 liters of industrial methanol to extract 6 times, each cold soaked for 7 days, filtered, combined methanol liquid, and recovered methanol under reduced pressure to obtain 1600g of total extract. The paste yield was 13.9%.

[0038] The second step of crude alkaloid extraction stage: 1600g of the total extract was repeatedly ground and dissolved with 16000mL of 1N hydrochloric acid, and filtered until the last test of the improved bismuth iodide potassium iodide showed a negative reaction, and the acid water was combined. The obtained acidic aqueous solution was adjusted to a pH of 4-5 with concentrated ammonia water, passed through a hydrogen-type cation exchange resin column, first eluted with 100 times the amount of sample-loaded deionized water until colorless, and then eluted with 20 times the ...

Embodiment 3

[0042] Embodiment 3: Extraction of swainsonine in Oxytropis gansu

[0043] The first step of extract extraction stage: Gansu Oxytropis hay powder 20kg, cold immersion extraction with 100 liters of industrial methanol 4 times, each cold immersion for 5 days, filtering, merging methanol liquid, and recovering methanol under reduced pressure to obtain 2230g of total extract. The paste rate was 11.2%.

[0044] The second step of crude alkaloid extraction stage: 2230g total extract was repeatedly ground and dissolved with 15000mL 1N hydrochloric acid, and filtered until the last acid water solution improved bismuth potassium iodide test showed a negative reaction, and the acid water solution was combined. The resulting acidic aqueous solution was adjusted to pH 4-5 with concentrated ammonia water, passed through a hydrogen-type cation exchange resin column, and first eluted with 100 times the amount of sample-loaded deionized water until it was colorless, and then eluted with 30 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com