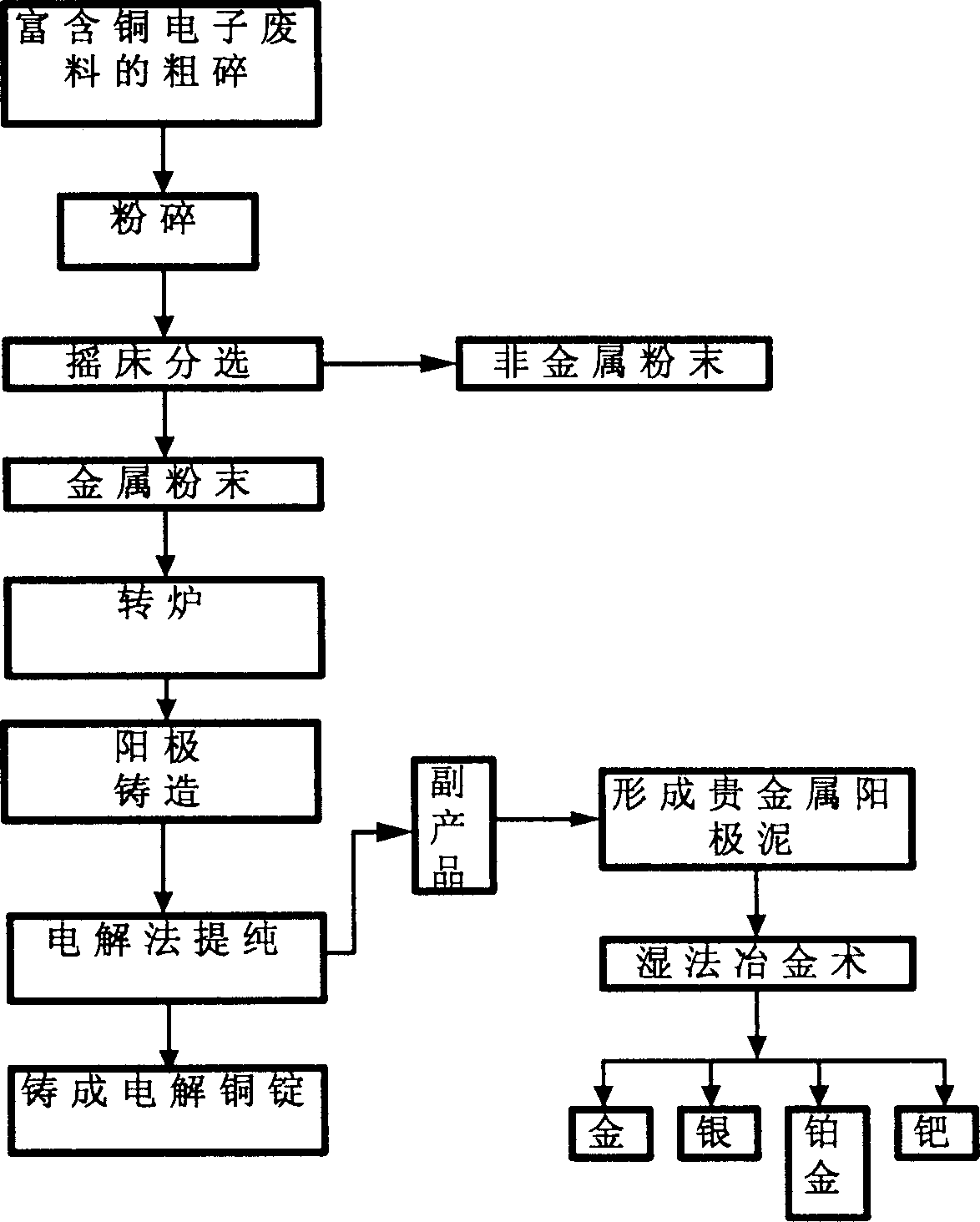

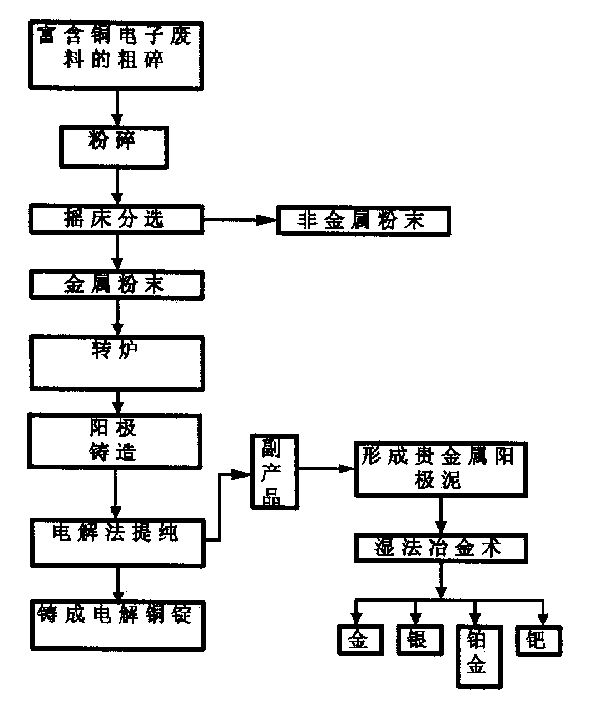

Process for recovering metal and non-metal materials from copper enriched electronic waste

A technology for non-metallic materials and electronic waste, applied in the field of recycling metals and non-metals, can solve the problem of high investment cost and achieve the effect of removing waste gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The present invention adopts SWP500 type plastic crusher to roughly crush the electronic waste, adopts SMP-400 type pulverizer to crush, and adds water spraying device during the crushing and crushing process. Use YT-T-2L shaker to realize the separation of metal powder and non-metal powder. Electrolytic copper is produced by casting metal powder into an anode using a converter for electrolysis. The process can effectively recover 95% of metals and all non-metals in electronic waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com