Catalyst

A catalyst body and catalyst technology, applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve the problems of reduced purification performance, reduced strength, particle growth, etc., and achieve excellent thermal durability and load strength High, the effect of inhibiting movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

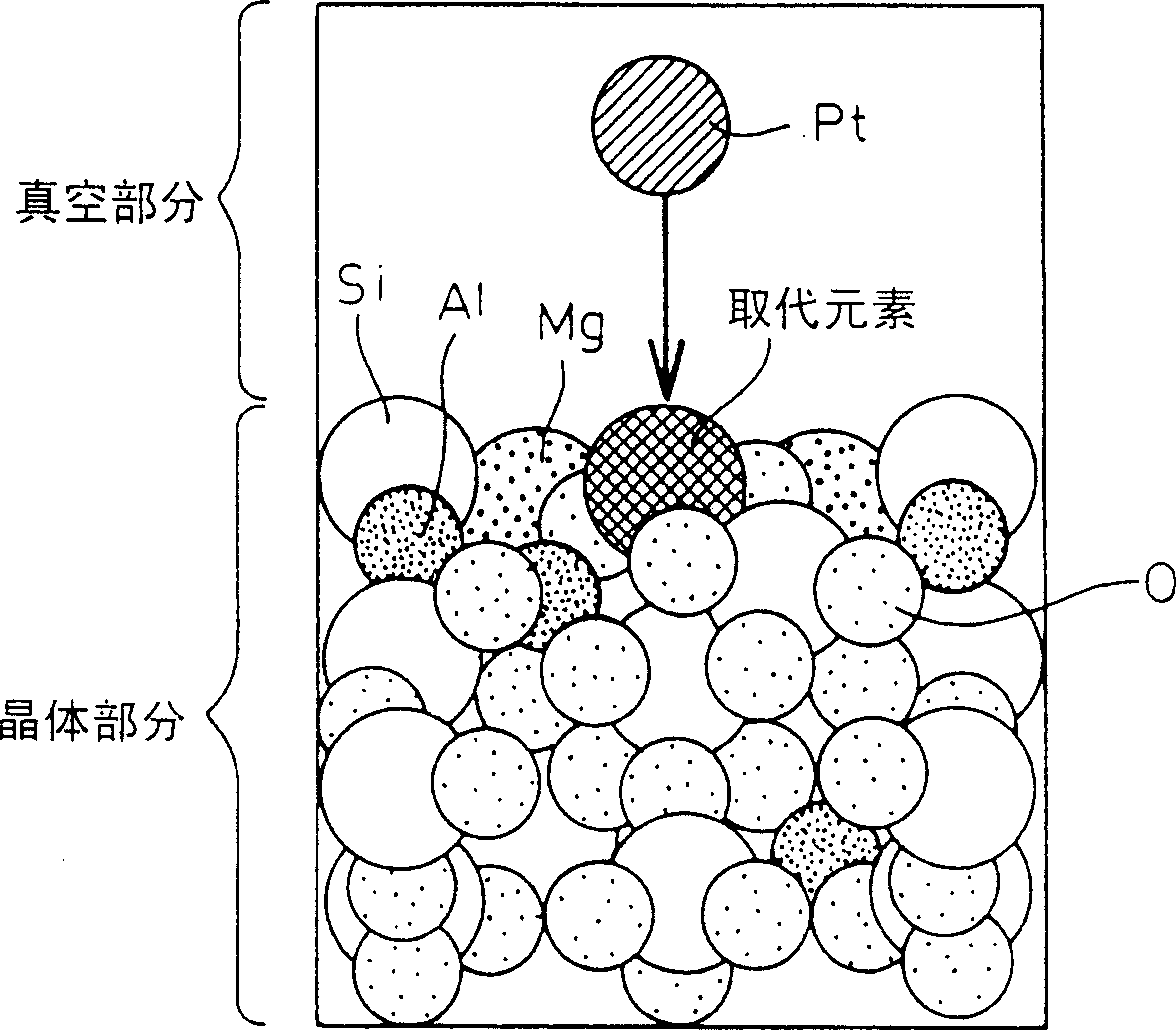

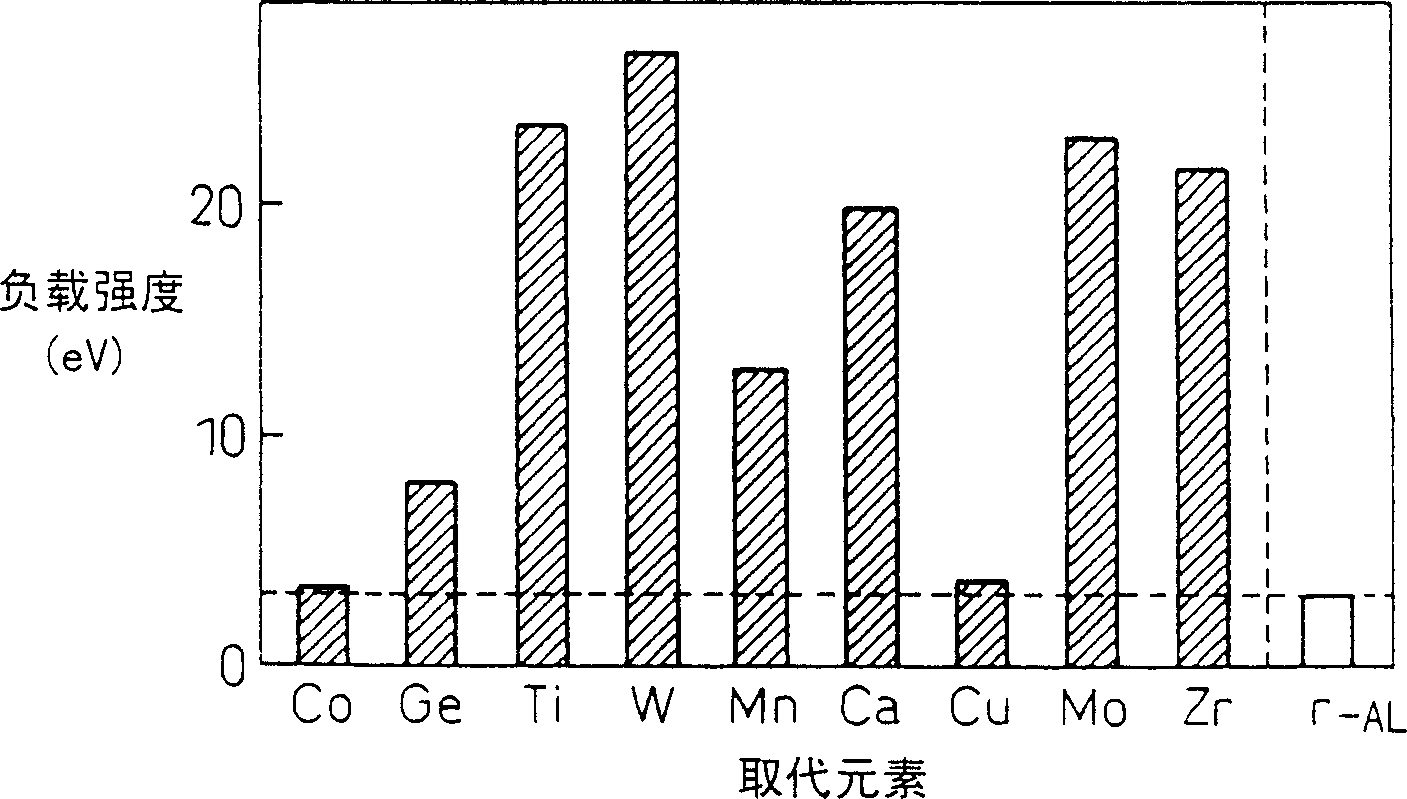

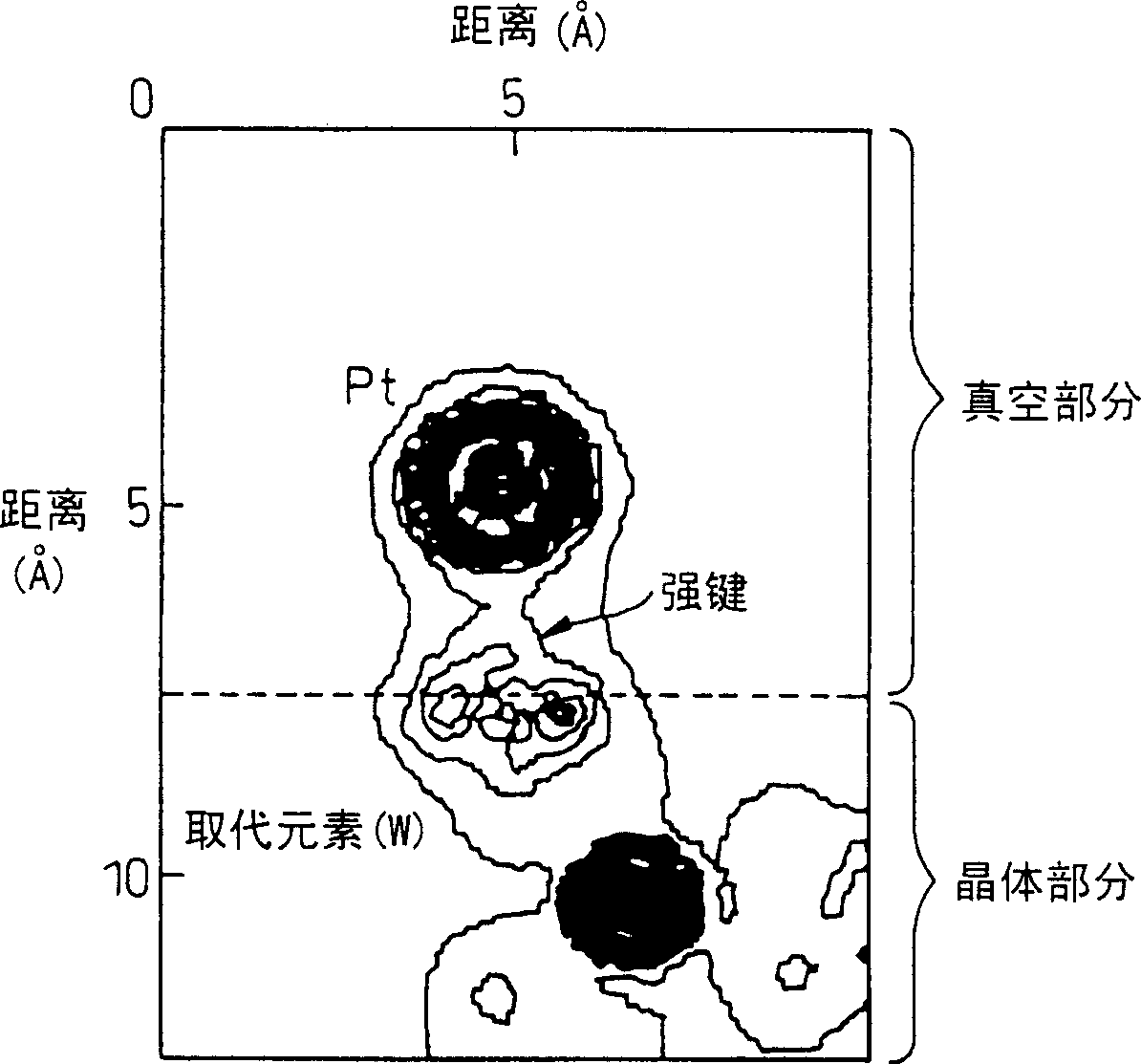

Method used

Image

Examples

Embodiment 1

[0041] Talc, kaolin, alumina, and aluminum hydroxide are used as cordierite materials, and 20% of the Al materials of the cordierite constituent materials are reduced. Then, WO equivalent to 10% of the constituent element Al was added so that the resulting composition was close to the theoretical composition point of cordierite. 3 and similar TiO equivalent to 10% Al element 2 . After adding an appropriate amount of binder, lubricant, humectant and water to the raw material, the mixture is kneaded and transformed into clay. The resulting clay was molded into a honeycomb structure with a cell wall thickness of 100 μm, a cell density of 400 cpsi, and a diameter of 50 mm. After drying, the honeycomb structure was sintered at 1,390° C. in air to obtain a ceramic support into which substituting elements W and Ti were introduced. Herein, two elements (W and Ti) were used as substituting elements in order to avoid lattice defects in cordierite.

[0042]In order to support the cat...

Embodiment 2 to 9

[0058] A ceramic catalyst body was prepared in the same manner as in Example 1, except that the elements replacing Al, the element constituting cordierite, were W and Co, and their oxides WO 3 and CoO are added to the cordierite raw material. Similarly, by substituting the element W, Ti or Zr, the WO 3 、TiO 2 or ZrO 2 Added to cordierite raw materials to prepare ceramic catalyst bodies (Examples 3 to 5). Since the substituting element is one kind (W) in Example 3, lattice defects appear simultaneously, and the substituting element (W) and the lattice defects simultaneously support the catalyst component (Pt). Examples 4 and 5 select substituting elements that do not generate (or hardly generate) lattice defects.

[0059] In Examples 6 to 9, the carrier substrate was replaced with alumina, tungsten oxide or titanium oxide shown in Table 1, and the internal support element for supporting the catalyst component (Pt) was replaced with W or Ti to prepare ceramic catalyst bodies...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com