Continuous chemical powder plating method and apparatus

An electroless plating and powder technology, which is applied in liquid electroless plating, coating, metal material coating process, etc., can solve the problems such as the inability to fundamentally solve the uniformity of metal coating and the inability to realize continuous production, so as to reduce labor strength, improve consistency, achieve continuous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

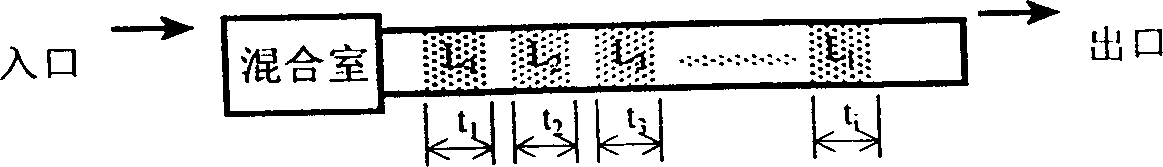

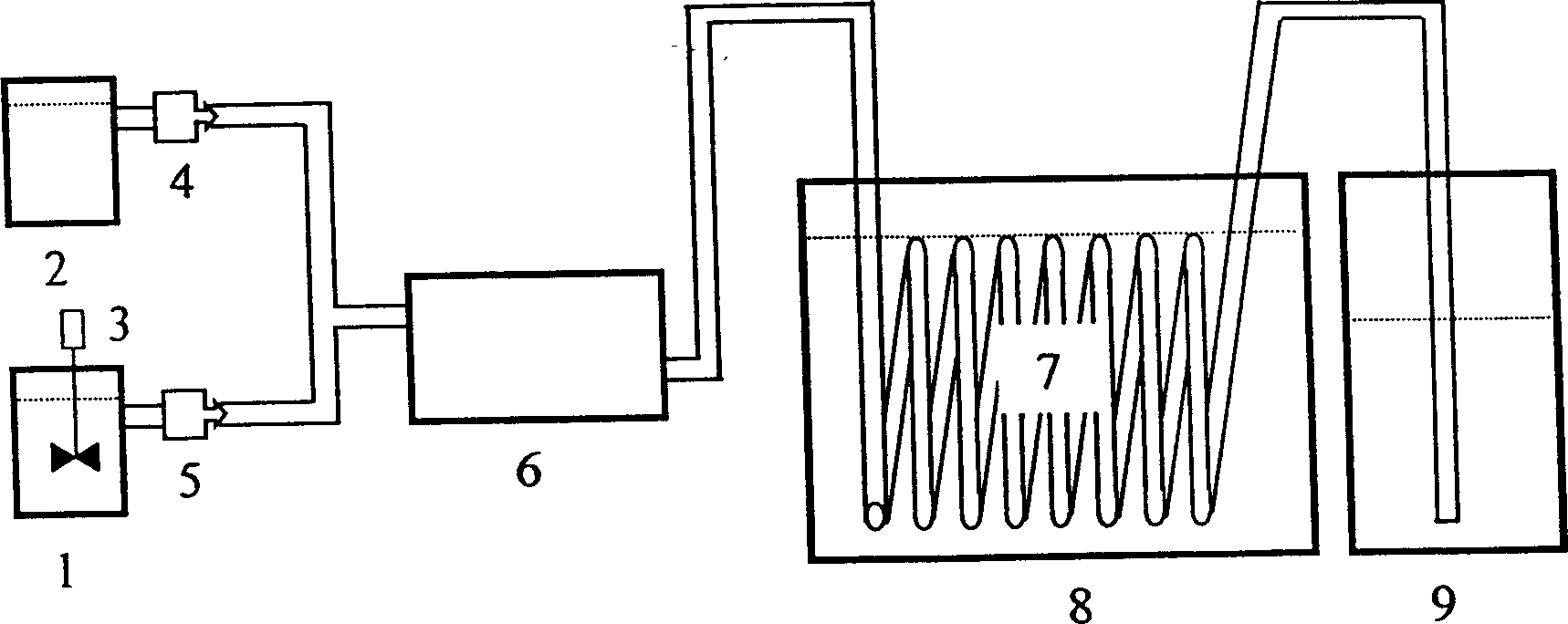

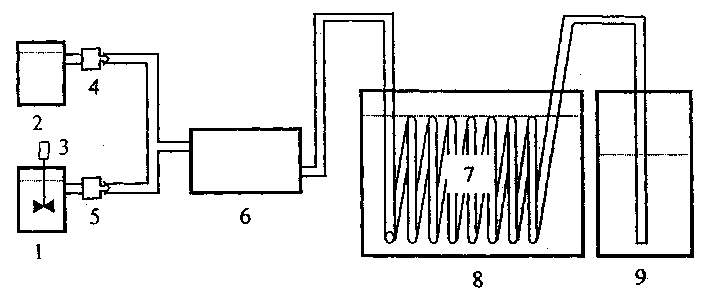

Method used

Image

Examples

Embodiment 1

[0045] 1) The pipe diameter is 20 mm, the flow rate is 7.2 liters / hour, and the length of the ultrasonic inner coil is 12 meters. The time for the solution to be irradiated by ultrasonic waves is 90 minutes, and the amount of raw material powder per hour is 648 grams.

[0046] 2) Metering pump power, specification: 600W, 10 liters / hour

[0047] 3) Ultrasonic power and frequency: 300W, 20~40KHz

[0048] 4) Composite powder: 720 g / h (metal content is 10% by weight)

[0049]5) Solution composition: nano-alumina powder with a size of 10-20nm. Add the sensitized and activated powder into the main salt solution containing 35 g / L of cobalt sulfate, 15 g / L of sodium citrate, and 40 g / L of boric acid, and stir to form a suspension L 1 ; another solution L 2 It is composed of sodium hypophosphite 20 g / L and a certain amount of NaOH, and the pH value of the mixture is 10.5. The obtained composite powder is observed by a transmission electron microscope, and is uniformly composited co...

Embodiment 2

[0051] 1) The diameter of the pipe is 20 mm, the flow rate is 35 liters / hour, the length of the ultrasonic inner coil is 60 meters, the time of the solution under ultrasonic irradiation is 90 minutes, and the amount of raw material powder per hour is 3240 grams.

[0052] 2) Metering pump power, specification: 3000W, 50 liters / hour

[0053] 3) Ultrasonic power and frequency: 1500W, 20~40KHz

[0054] 4) Composite powder: 6480 g / h (metal content is 50% by weight)

[0055] 5) Solution composition: micron titanium oxide powder with a size of 0.8-1.2 μm. The sensitized and activated powder is added to the reducing solution L containing sodium hypophosphite 15 g / L and a certain amount of H2SO4 1 In, stirring to form a suspension; another solution is the main salt solution L of nickel sulfate 30 g / L, sodium citrate 17 g / L, and sodium acetate 15 g / L 2 , the pH value of the mixture is 4.5. Results Observation by scanning electron microscope showed that nickel was evenly coated on th...

Embodiment 3

[0057] 1) The pipe diameter is 20 mm, the flow rate is 7.2 liters / hour, the ultrasonic inner coil is 12 meters long, the solution is irradiated by ultrasonic waves for 30 minutes, and the amount of raw material powder per hour is 648 grams.

[0058] 2) Metering pump power, specification: 600W, 10 liters / hour

[0059] 3) Ultrasonic power and frequency: 300W, 20~40KHz

[0060] 4) Composite powder: 1296 g / h (metal content is 50% by weight)

[0061] 5) Solution composition: micron tin oxide powder with a size of 1-5 μm. The sensitized and activated powder is added with reducing solution L containing 6 g / L of formaldehyde and 2.2 mL / L of methanol 1 In, stirred to form a suspension; another solution L 2 It is composed of 17.5 g / L silver nitrate, 35 g / L ammonia water and 2 g / L sodium hydroxide. The obtained composite powder is observed by a scanning electron microscope, and it is a powder in which Ag is uniformly compounded on the surface of the tin oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com