L-arginine producing strain and its mutation method and usage in producing L-arginine

An arginine and high arginine technology, applied in bacteria, fermentation and other directions, can solve the problems of difficult process amplification, single structural analog, reverse mutation, etc., and achieve improved genetic stability, good genetic stability, and yield traits. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

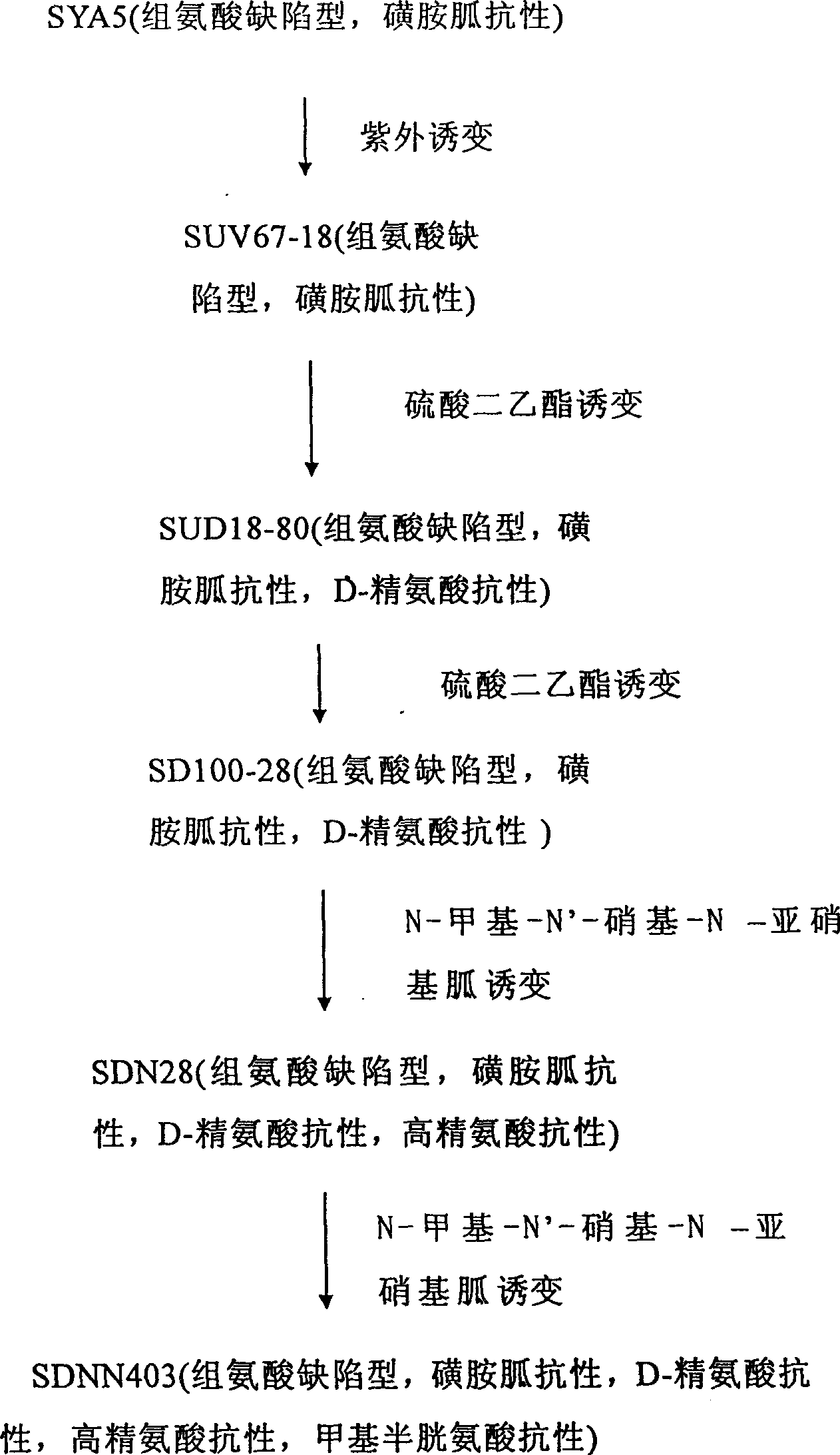

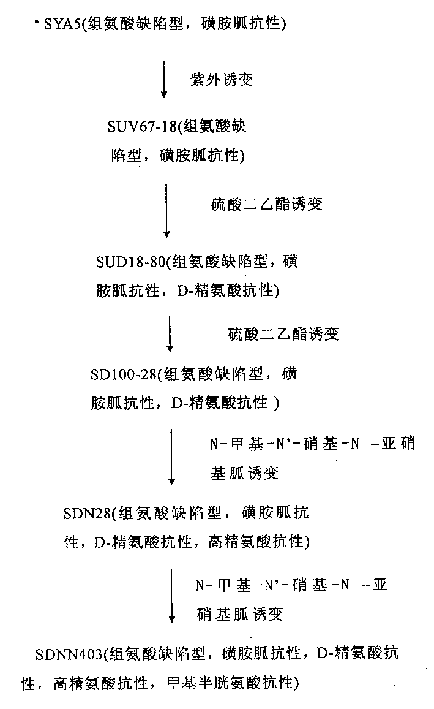

[0032] Preparation of mutants resistant to sulfaguanidine, D-arginine, homoarginine and methylcysteine and fermentative production of L-arginine.

[0033] The starting strain SYA5 was subjected to ultraviolet mutagenesis and diethyl sulfate mutagenesis to obtain the SD100-28 strain, and the nitrosoguanidine mutagenesis was continued, and the SD100-28 strain was inserted into the seed medium and cultivated until the middle and late logarithmic growth stages. 50% of the inoculum was transferred to fresh seed medium and cultured for 5 hours to achieve synchronous culture of the cells. Aseptically centrifuge the culture solution, collect the bacteria, wash with 0.1mol / l, pH6.0 phosphate buffer for 2 to 3 times, transfer to a Erlenmeyer flask with glass beads to disperse, obtain a bacterial suspension, and control the cell concentration at 10 8A / ml or so. Weigh a small amount of nitrosoguanidine and dissolve it in a small amount of acetone, then add phosphate buffer to prepare ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com