Method of producing composite organic fertilizer using city sludge

A technology of urban sludge and organic fertilizer, applied in the preparation of organic fertilizer, organic fertilizer, sewage/sludge fertilizer, etc., can solve the problems of pollution, softening, mildew heavy metals, etc., to reduce toxicity and reduce sludge output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, prepare three-dimensional compound fertilizer:

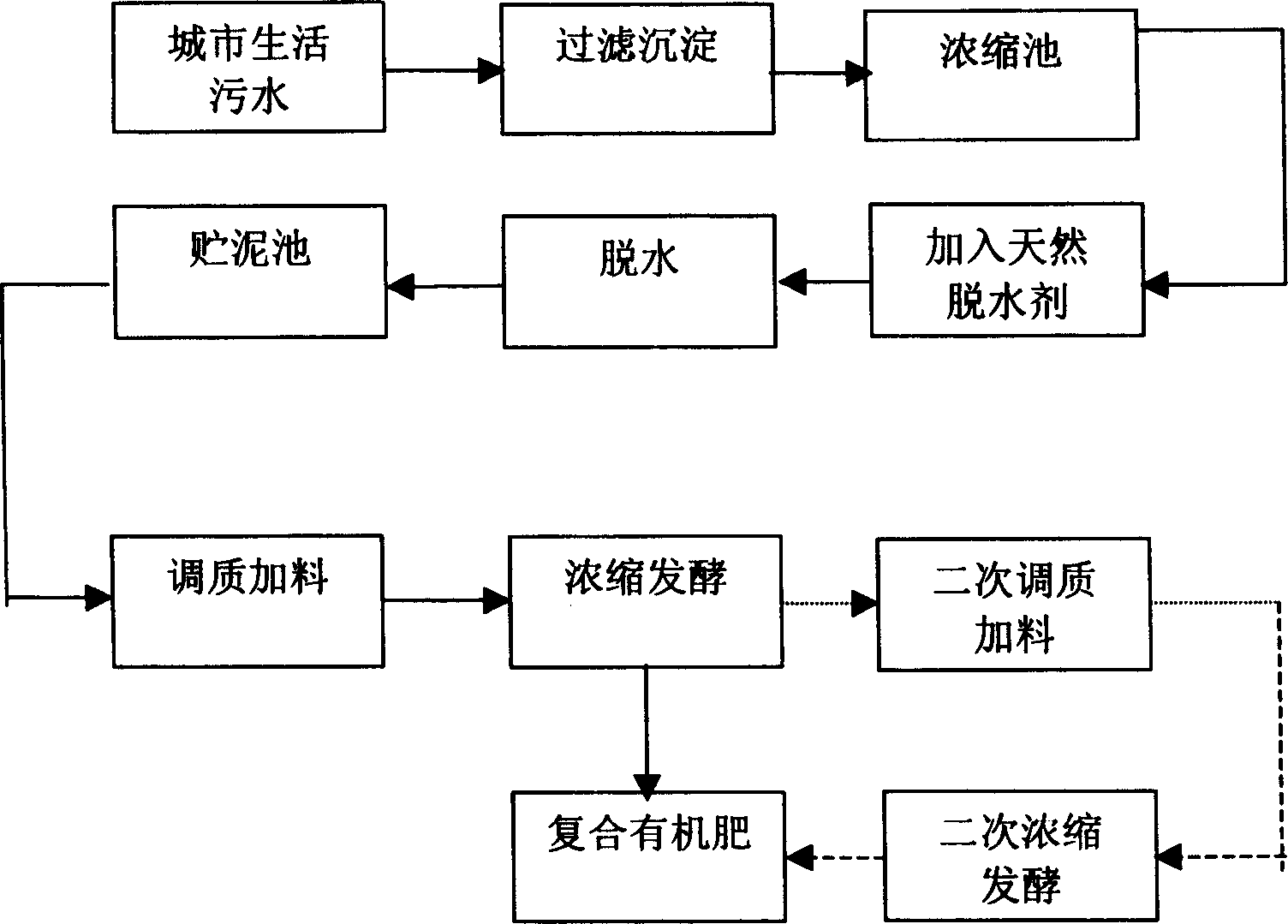

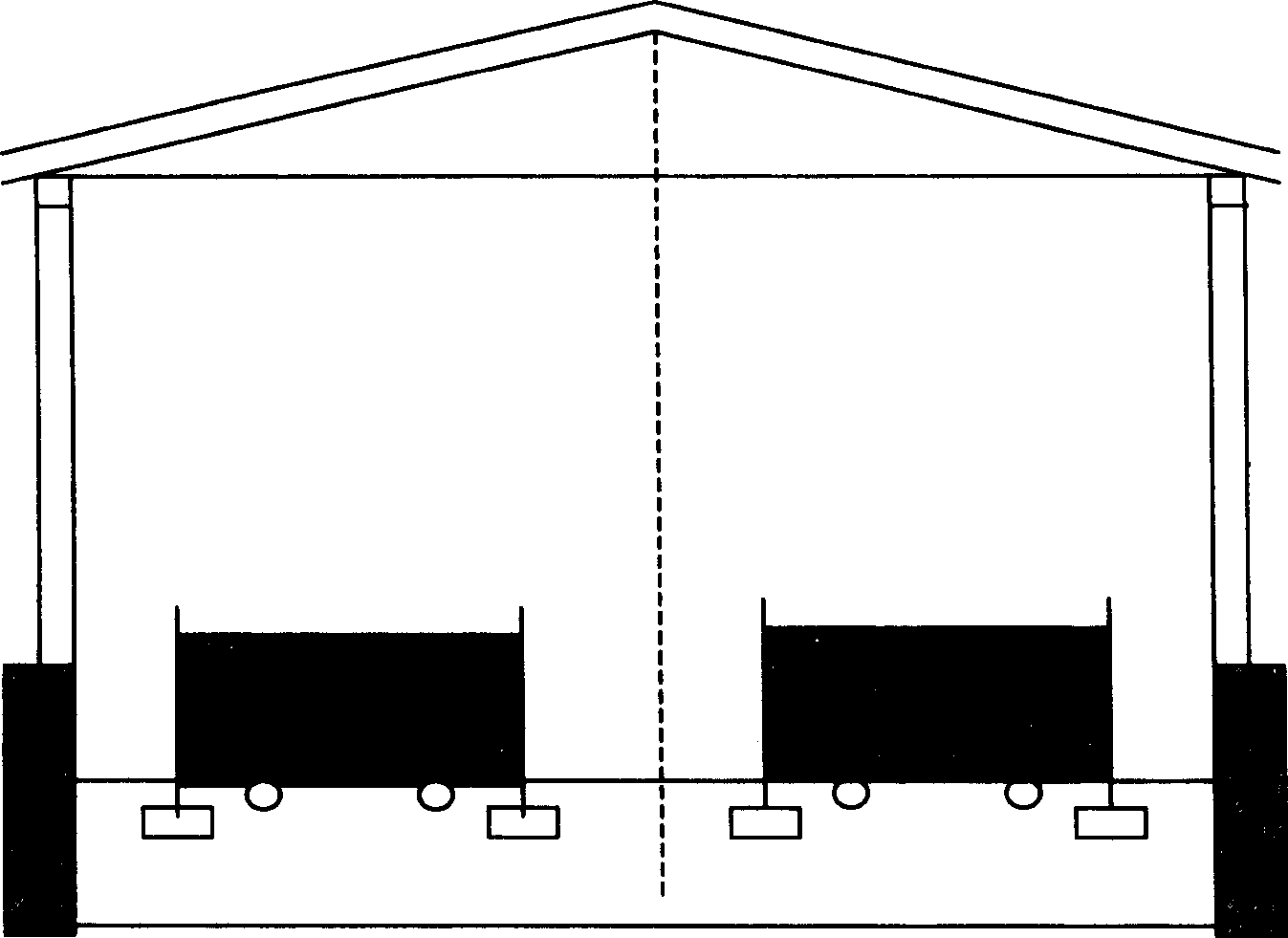

[0026] For its preparation process, please refer to figure 1 , the solid line in the figure represents the flow of this embodiment. First, filter and settle the urban sewage, take the settled sludge into the thickening tank, add natural seaweed as a dehydrating agent according to the proportion of 10% of the thickening tank volume, make the sludge semi-flocculated, and dehydrate it in the dehydration machine room, and the dehydrated sewage The mud is sent to the solar concentration fermentation device for conditioning, and its formula ratio is: sludge 50-60%, urea 5-10%, potassium chloride 2-5%, diammonium 1%, pine needle powder 5%, alfalfa powder 3 %, straw powder 8%, other 8-26%, make C / N=30 / 1, add 3% phosphoric acid neutralizing material (for drying chicken manure, pig manure or cow manure) and 3% heavy metal passivation material (for humic acid powder, fly ash, peat soil, etc.), and add 5% of fertile s...

Embodiment 2

[0028] Embodiment 2, prepare high-efficiency nutrient soil:

[0029] see figure 1 Shown by the dotted line. Its operating conditions are the same as in Example 1, and the difference from Example 1 is that the conditioned compost is conditioned again to make C / N=25 / 1, and 5% of fertile soil is added to carry out secondary fermentation as a primer. The pile temperature is ≥55°C, and the time is more than 3 days, and then the pile is turned or dried to make the moisture ≤18%, and then crushed to make nutrient soil. Its total nitrogen, phosphorus and potassium nutrients are ≥2%, organic matter is ≥38%, and the number of viable VT bacteria is ≥1×10 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com