Catalyst utilized to prepare hydrocarbon from synthesis gas and its preparation method

A catalyst and synthesis gas technology, applied in the recovery of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of easy wear and short service life of the catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 98 kg of natural magnetite was magnetically separated to remove excess SiO 2 (retention 2 , S, P, etc., add 2 kg of Al 2 o 3 , 1 kg KNO 3 , 1 kg of CaCO 3 , mixed evenly, heated to 1500°C to melt, generally, preferably stable for 8 hours, rapidly cooling the molten liquid, and crushing to obtain the catalyst of the present invention.

Embodiment 2

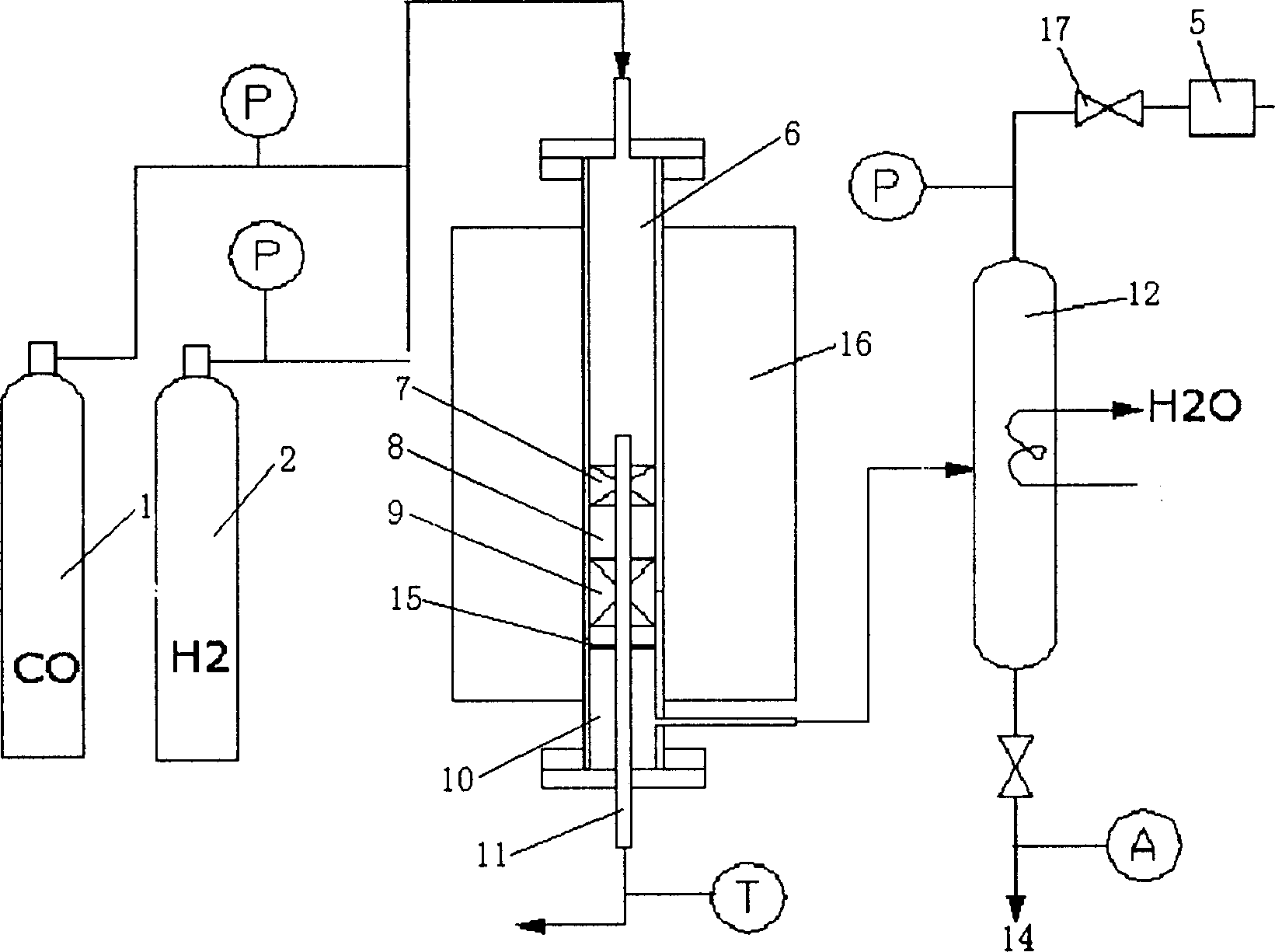

[0023] (1) is CO cylinder, (2) is H 2 Steel cylinders, after pressure measurement and mass flow meter measurement at room temperature, adjust the valve to open to make H 2 : CO = 2: 1 (mole), the space velocity based on the catalyst is 2000h -1 , the pressure is 2.0MPa into the tubular fixed-bed reactor (6). The inner diameter of the tubular fixed-bed reactor (6) is 25.4mm, and a φ8×1.5 thermocouple tube (11) is arranged in the center, the lower part is a stainless steel support body (10), and the upper part is a flower plate and a stainless steel wire mesh (15). Fill 60 mesh, 80 mesh, 120 mesh, 180 mesh, 240 mesh quartz sand (9) successively above the screen, mix and fill in (8) according to quartz sand (240 mesh): catalyst=50 grams: 10 grams, its top Refill 240 orders, 180 orders, 120 orders, 80 orders, 60 orders quartz sand (7). The tubular fixed bed reactor (6) is placed in the electric furnace (16). Adjust the amount of current passing through the electric furnace (16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com