Orgaic polymer-inorganic nano composite resistance type thin film humidity sensitive element and its manufacturing method

An organic polymer, inorganic nanotechnology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as unsatisfactory stability and reliability, poor resistance to high humidity environments, and hindering the practical application of humidity sensors. Achieve the effect of improving resistance to high humidity environment, good component consistency, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

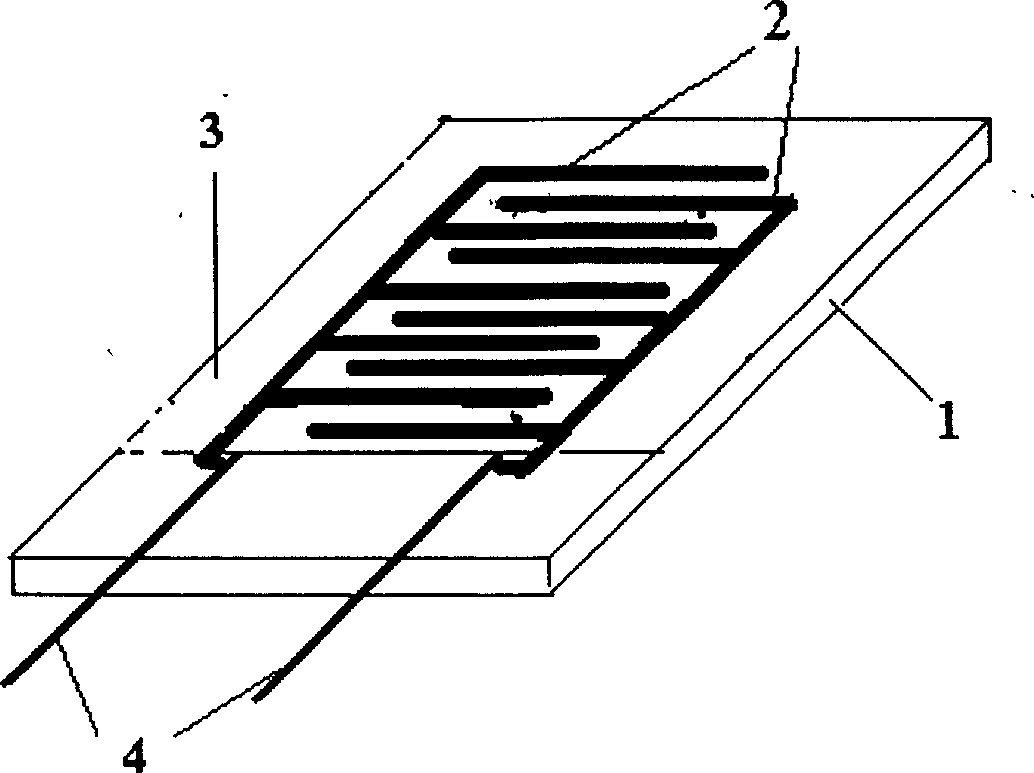

preparation example Construction

[0018] The preparation method of the humidity sensitive film is to use a dipping machine to immerse the glass-ceramic interdigitated gold electrode in the moisture-sensitive liquid for 1-3 minutes, pull it out, dry it at room temperature for 20-60 minutes, and heat it at 80-140°C 0.5 to 4 hours, then placed in an acidic aqueous solution with a pH of 1 to 6 for 2 to 60 minutes, then dried the element, and heated at 80 to 120° C. for 1 to 4 hours.

[0019] The moisture-sensitive liquid is (1) a silicon-containing polyelectrolyte having a structure (I), wherein X- is a halide ion, and the letter y is a number of 1-8;

[0020] (2) Nano ZnO colloid, wherein the size of inorganic nanoparticles is less than 50 nanometers. The two are configured at a weight ratio of 1:0.05-0.6 to form an ethanol solution with a weight percent concentration of 0.5%-5%.

Embodiment

[0022] 1) Electrode cleaning

[0023] Soak the glass-ceramic interdigitated gold electrode in absolute ethanol and acetone, ultrasonically clean it, and dry it for later use;

[0024] 2) Dip coating of humidity sensitive film and post-treatment

[0025] Use a dipping machine to immerse the ceramic interdigitated gold electrode in the moisture-sensitive solution for 1 to 3 minutes, then pull it out, dry it naturally at room temperature for 20 to 60 minutes, heat treat it at 80 to 140°C for 0.5 to 4 hours, and then place it at PH = 1 to 6 in acidic aqueous solution for 2 to 60 minutes, then dry the element and heat at 80 to 120°C for 1 to 4 hours.

[0026] The moisture-sensitive liquid is (1) a silicon-containing polyelectrolyte with a (II) structure;

[0027] (2) Nano ZnO colloid, wherein the size of inorganic nanoparticles is less than 50 nanometers. The two are configured at a weight ratio of 1:0.05-0.6 to form an ethanol solution with a weight percent concentration of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Interdigital spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com