Method of preparing branched polyethylene glycol

A polyethylene glycol and branched technology, which is applied in the fields of biomedicine and protein chemistry, can solve the problems of biodegradation, difficult control of reaction conditions, and high price of branched polyethylene glycol, and achieve high yield and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

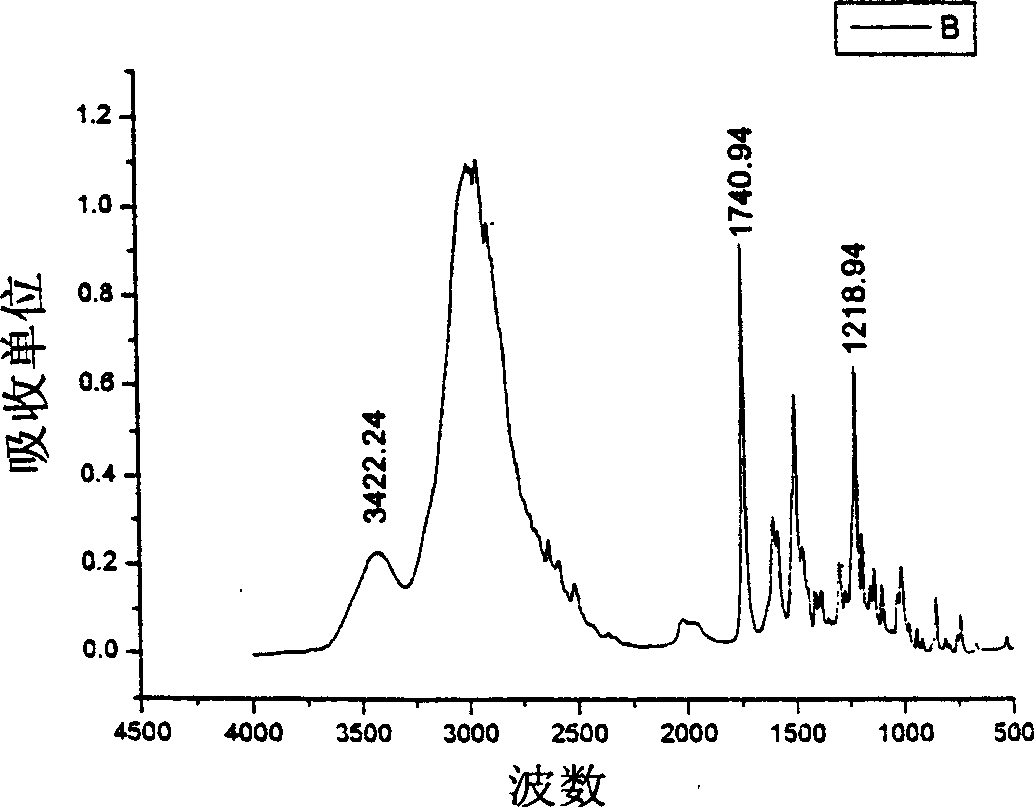

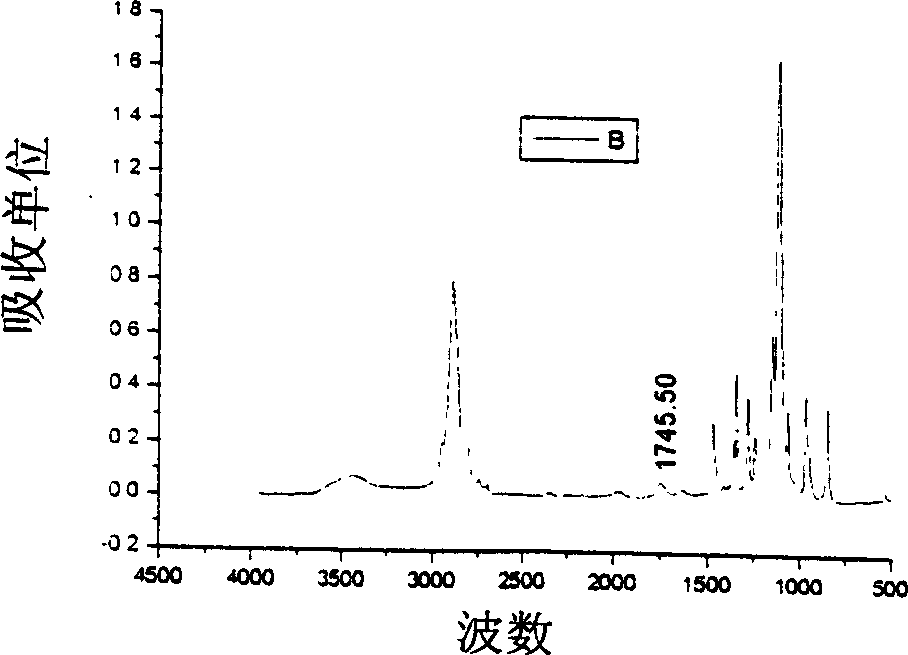

[0048] The structure of the target product can be passed through MALDI-TOF ( image 3 ) Spectrogram and 1 H NMR( Figure 6 ) Confirmed. Example 2. Using the method of the present invention to prepare a branched polyethylene glycol, the steps are:

[0049] 1. Preparation of lysine ethyl ester hydrochloride

[0050] Dissolve L-lysine in absolute ethanol (1:8 molar ratio), add dry hydrogen chloride gas to saturation under stirring conditions, heat to reflux to dissolve L-lysine, leave this solution overnight; then reduce Press distillation to remove excess ethanol and hydrogen chloride; finally, use anhydrous ether to crystallize lysine ethyl ester hydrochloride; then filter, wash, and dry to obtain lysine ethyl ester hydrochloride light yellow crystals;

[0051] 2. Preparation of carboxymethylated monomethoxy polyethylene glycol with a molecular weight of 2000

[0052] Dissolve 25 grams of mPEG2000 in dry dichloromethane, add 20 grams of activated manganese dioxide, mix homogeneously...

Embodiment 3

[0058] The structure of the target product can be passed through MALDI-TOF ( image 3 ) Spectrogram and 1 H NMR( Figure 6 ) Confirmed. In Example 3, a branched polyethylene glycol is prepared by the method of the present invention, and the steps are:

[0059] 1. Preparation of lysine ethyl ester hydrochloride

[0060] Dissolve L-lysine in absolute ethanol, add dry hydrogen chloride gas to saturation under stirring, heat to reflux to dissolve L-lysine, leave the solution overnight; then distill under reduced pressure to remove excess ethanol and hydrogen chloride ; Finally, use anhydrous ether to crystallize lysine ethyl ester hydrochloride; then filter, wash, and dry to obtain lysine ethyl ester hydrochloride light yellow crystals;

[0061] 2. Preparation of carboxymethylated monomethoxy polyethylene glycol with a molecular weight of 750

[0062] Dissolve mPEG750 in dry dichloromethane, add activated manganese dioxide, mix evenly, stir overnight at room temperature; filter to remo...

Embodiment 4

[0069] In Example 4, a branched polyethylene glycol is prepared by the method of the present invention, and the steps are:

[0070] 1. Preparation of lysine ethyl ester hydrochloride

[0071] Dissolve L-lysine in absolute ethanol, add dry hydrogen chloride gas to saturation under stirring, heat to reflux to dissolve L-lysine, leave the solution overnight; then distill under reduced pressure to remove excess ethanol and hydrogen chloride ; Finally, use anhydrous ether to crystallize lysine ethyl ester hydrochloride; then filter, wash, and dry to obtain lysine ethyl ester hydrochloride light yellow crystals;

[0072] 2. Preparation of carboxymethylated monomethoxy polyethylene glycol with a molecular weight of 10,000

[0073] Dissolve mPEG10000 in dry dichloromethane, add activated manganese dioxide, mix evenly, stir overnight at room temperature; filter to remove the catalyst, and evaporate the solvent under reduced pressure to obtain the intermediate oxidation product;

[0074] Di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com