Method for synthesizing EMC (Ethylmethyl Carbonate) through homogeneously precipitating solid base catalyst

A solid base catalyst, methyl ethyl carbonate technology, applied in the preparation of organic carbonate, chemical instruments and methods, catalyst activation/preparation and other directions, can solve the problems of polluted products, product difficulties, long reaction period and other problems, and achieve component distribution The effect of uniformity, high production efficiency and large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

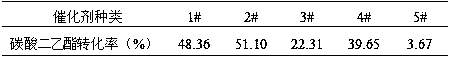

[0051] In a three-necked flask, 45 g of dimethyl carbonate and 59 g of diethyl carbonate were charged, the molar ratio of the two was 1:1, and the homemade 20% Ca / SiO 2 (1#), 20% Mg / SiO 2 (2#), 20% Fe / SiO 2 (3#), 20% Cs / SiO 2 (4#), 20% Zn / SiO 2 (5#), 20% Cu / SiO 2 (6#), 20% Ba / SiO 2 (7#), 20% K / SiO2 2 (8#), 20% Ag / SiO 2 (9#), 20% Mn / SiO 2 (10#), 20% Au / SiO 2(11#), 20% Mg / Al 2 o 3 -SiO 2 (12#), 20% Mg / TiO 2 -SiO 2 (13#), 20%Mg / ZrO 2 -SiO 2 (14#), 10% Mg-10% Fe / Al 2 o 3 -SiO 2 (15#), 10% Mg-10% Cs / Al 2 o 3 -SiO 2 (16#), 10%Zn-10%Cu / Al 2 o 3 -SiO 2 (17#), 10% Ba-10% K / Al 2 o 3 -SiO 2 (18#), 10% Mn-10% Ag / Al 2 o 3 -SiO 2 (19#), 10% Mg-10% Cs / Al 2 o 3 -TiO 2 -SiO 2 (20#), 7.5% Ca-7.5% Mg-5% Cs / Al 2 o 3 -SiO 2 (21#), 7.5% Mg-7.5% Ca-5% La / Al 2 o 3 -SiO 2 (22#), 7.5% Ca-7.5% Cs-5% Mn / Al 2 o 3 -SiO 2 (23#), 7.5% Mg-7.5% Cs-5% Mn / Al 2 o 3 -TiO 2 -SiO 2 (24#), 7.5% Mg-7.5% Cs-5% Mn / Al 2 o 3 -ZrO 2 -SiO 2 (25#) Catalyst Each catalyst, the ...

Embodiment 2

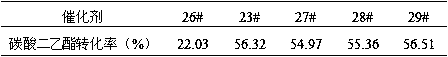

[0066] In the fixed bed reactor, the mass ratios of homemade carrier, metal salt solution and urea are 1:0.2:1 (26#), 1:0.2:5 (23#), 1:0.2:10 ( 27#), 1:0.4:5 (28#), 1:0.6:5 (29#) of 7.5% Ca-7.5% Cs-5% Mn / Al 2 o 3 -SiO 2 Catalysts were 50 g each (the source of the active components was the same as 23#), and the amount of deionized water in the preparation process was 15 times the mass of the raw materials; the temperature of the oil bath was gradually heated from room temperature to 90 °C, and the retention time was 6 h, and the aging time of the catalyst was 3 h; the amount of catalyst washing solvent was 10 times that of the catalyst, the drying temperature was 80 °C, and the drying time was 6 h; the catalyst was roasted at 500 °C, and the roasting time was 3 h; Diethyl ester is pumped into the reactor according to the molar ratio of 1:1, under normal pressure conditions, the reaction temperature is 150 °C, and the mass space velocity of raw materials is 20 h -1 After 10...

Embodiment 3

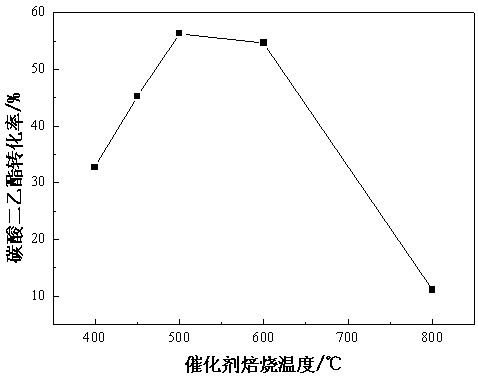

[0071] In the fixed-bed reactor, the self-made 7.5%Ca-7.5%Cs-5%Mn / Al with roasting temperatures of 400, 450, 500, 600, and 800°C were loaded respectively. 2 o 3 -SiO 2 Each catalyst is 50 g (the source of the active component is the same as 23#), in which the mass ratio of carrier, metal salt solution, and urea is 1:0.2:5, and the amount of deionized water in the preparation process is 15 times the mass of the raw material; the oil bath temperature Gradually heated from room temperature to 90°C, the holding time was 6 h, the catalyst aging time was 3 h; the amount of catalyst washing solvent was 10 times that of the catalyst, the drying temperature was 80°C, and the drying time was 6 h; the catalyst roasting time was 3 h ; Use a constant flow pump to pump dimethyl carbonate and diethyl carbonate into the reactor according to the molar ratio of 1:1, under normal pressure conditions, the reaction temperature is 150 ° C, and the mass space velocity of raw materials is 20 h -1 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com