Light scattering reflection substrate?use photosensitive resin composition, light scattering reflection substrate, and production methods therefor

A technology of photosensitive resin and reflective substrate, applied in the field of photosensitive resin composition for light scattering/reflective substrate, light scattering/reflective substrate, which can solve the limitation of manufacturing method selection, lack of sufficient, adhesion (poor adhesion, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

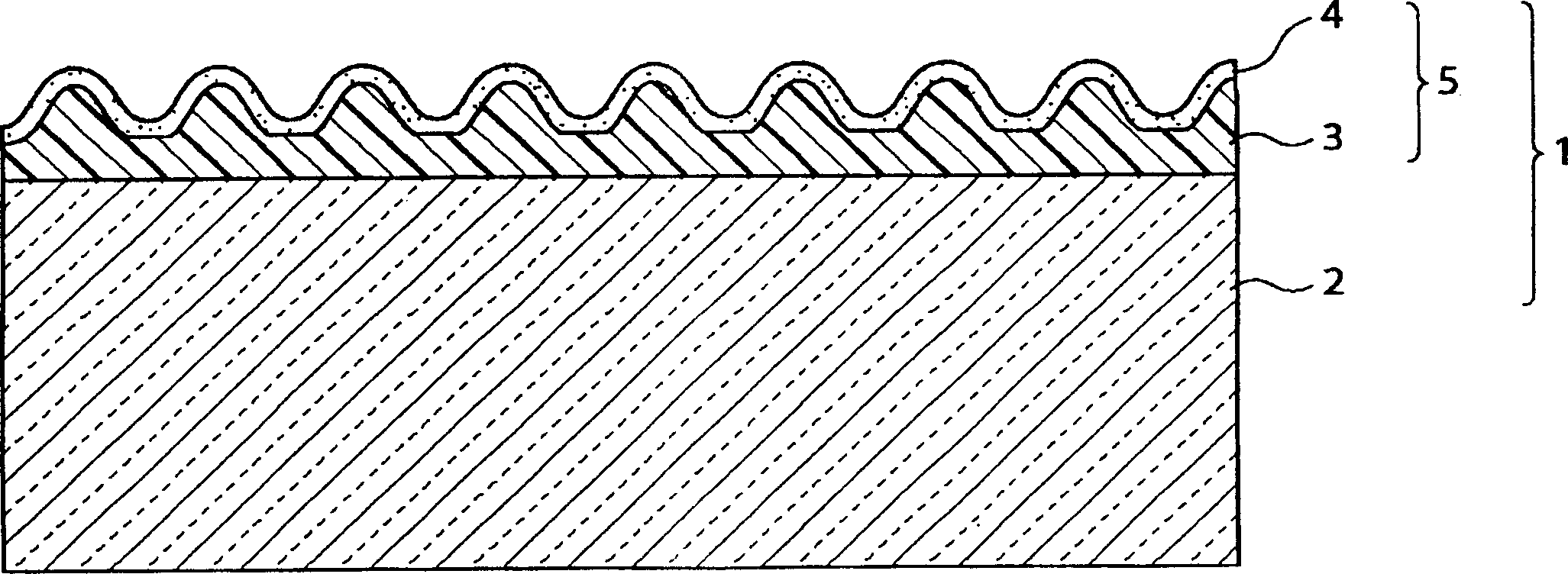

[0083] Colloidal silica (PGMEA-silica sol manufactured by Nissan Chemical Industry Co., Ltd.) is used as an inorganic component, and polyvinylphenol-based resist resin (AZ-DX5400P manufactured by Clariant Co., Ltd.) is used as a binder. Form a light-scattering film 3.

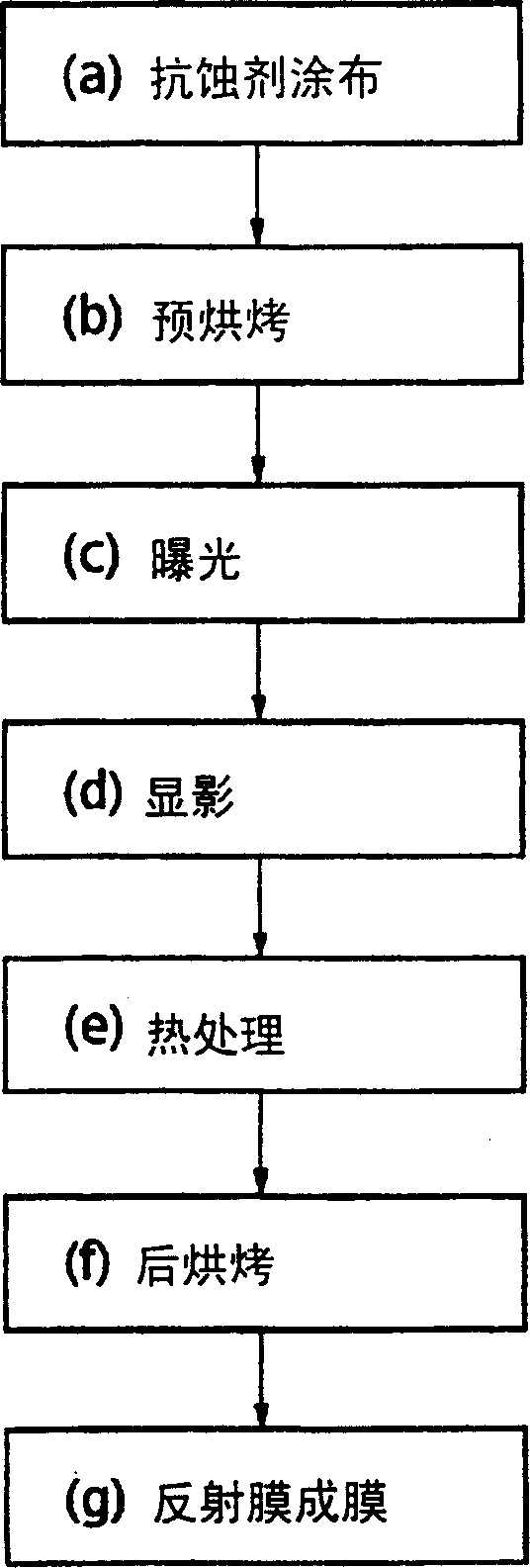

[0084] That is, after coating a coating solution obtained by mixing 7.5 g of colloidal silica (30 wt % solution) and 2 g of resist resin solution (solvent) on a glass substrate 2 made of soda lime silicate (thickness: 1 μm), Drying by solvent (heat treatment at 90°C for 30 seconds), exposure (using a photomask at 1000mJ / cm 2 Exposure), sensitization (in order to improve the contrast of the displayed image obtained by the uneven surface of the light scattering film 3, heat treatment at 90° C. for 30 seconds), development (10 seconds with PDA523AD (manufactured by JSR). second development), rinsing (cleaning with a pure water shower), drying, and fixing (heat treatment at 200° C. for 30 minutes) to produce the l...

Embodiment 2

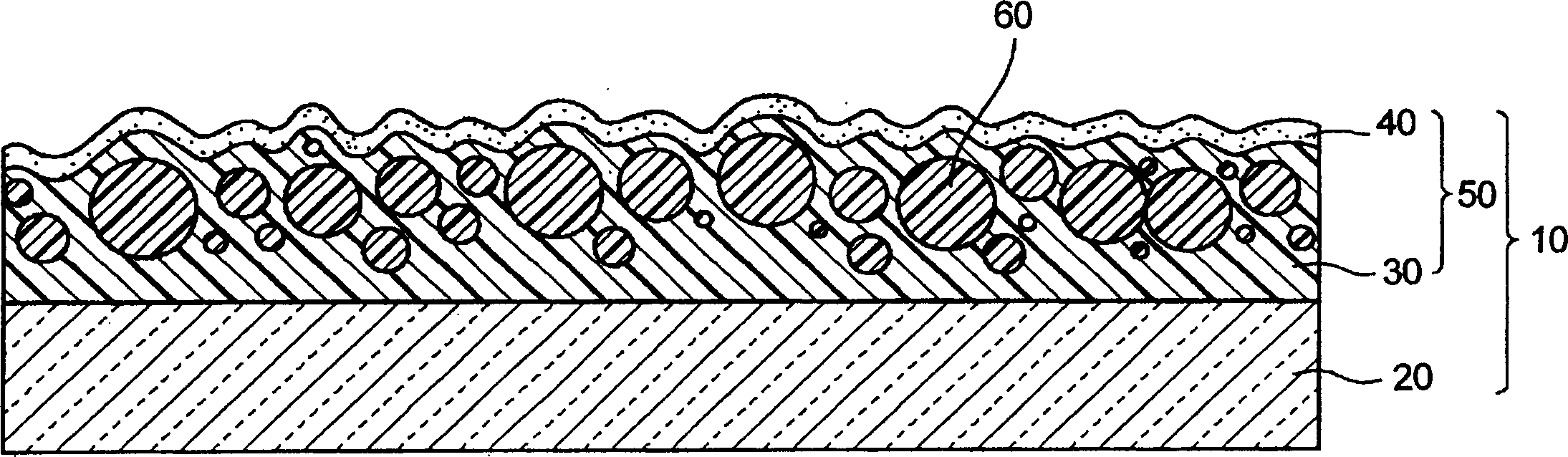

[0088] Using silica powder (eg, Aerosil) as an inorganic component, and using a transparent thermosetting (or light-curing) resin (eg, epoxy resin) as a binder, the light-scattering film 3 is produced by the following method.

[0089] That is, after coating the coating solution obtained by mixing 8.5g Aerosil and 1.5g catalytic curing type single-component epoxy resin on the glass substrate 2, a mold with an ideal concave-convex shape inverted pattern was attached to the coating surface, and the After heating (or lighting from the glass surface) to harden the epoxy resin, the mold is removed and cooled to produce a light-scattering film 3 in which a desired concave-convex shape is transferred. A reflective film 4 made of aluminum was formed on the light-scattering film 3 by a vacuum deposition method to form a light-scattering / reflective substrate 1, and its adhesiveness was measured by the above-mentioned cross-cut peeling test. As shown in Table 1, it has Good adhesion (100 / ...

Embodiment 3

[0091] Using silica powder (eg, Aerosil) as an inorganic component, and using a metal alkoxide (eg, tetraethoxysilane: TEOS) as a binder, the light-scattering film 3 is produced by the following method.

[0092] That is, 6 g of Aerosil and 20.8 g of TEOS were dispersed in a mixed solvent composed of 86 g of ethanol and 7.2 g of pure water, TEOS was hydrolyzed, and the hydrolyzed solution was applied to a glass substrate 2, dried and baked. Step, the light-scattering film 3 is produced. The aluminum reflective film 4 was formed into a film on the light scattering film 3 by vacuum deposition to make a light scattering / reflective substrate 1, and the above-mentioned cross-cut peeling test was used to measure its adhesiveness. As shown in Table 1, it had good Adhesion (100 / 100). Comparative example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com