Making method of fluor apatite

A technology of fluoroapatite and hydroxyapatite, which is applied in the field of fluoroapatite production, can solve the problems that the actual mechanism cannot be confirmed and the degree of demineralization can be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

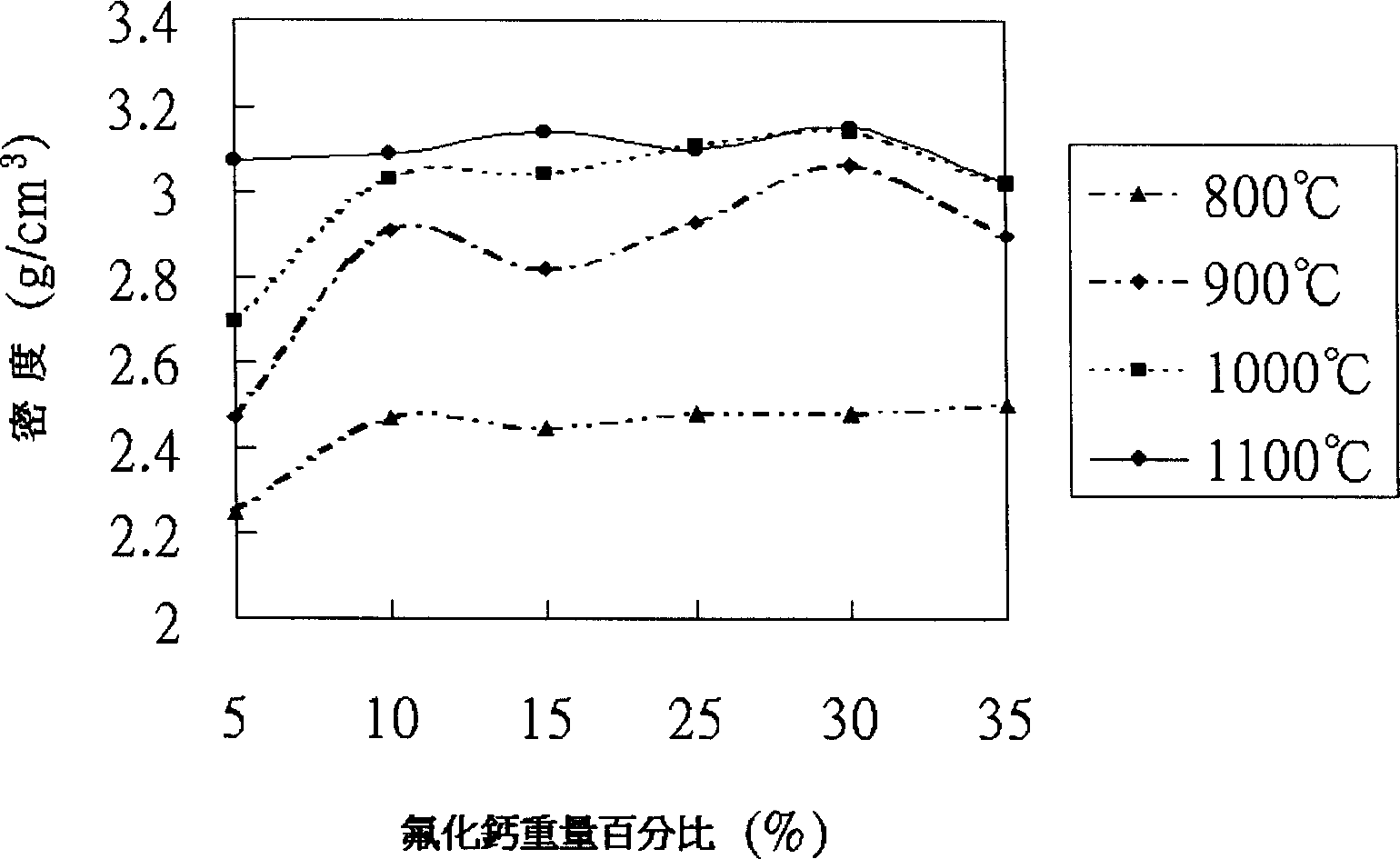

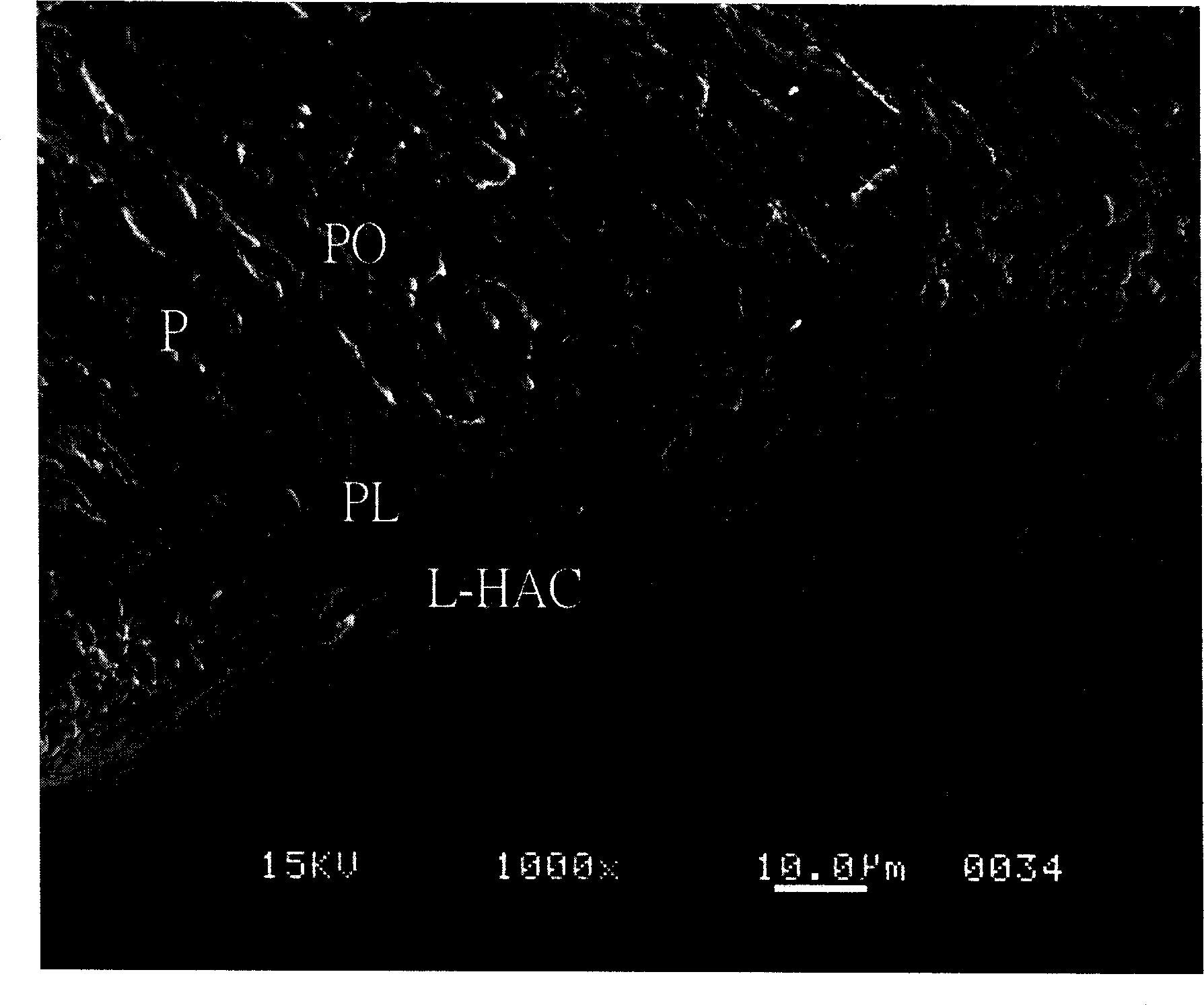

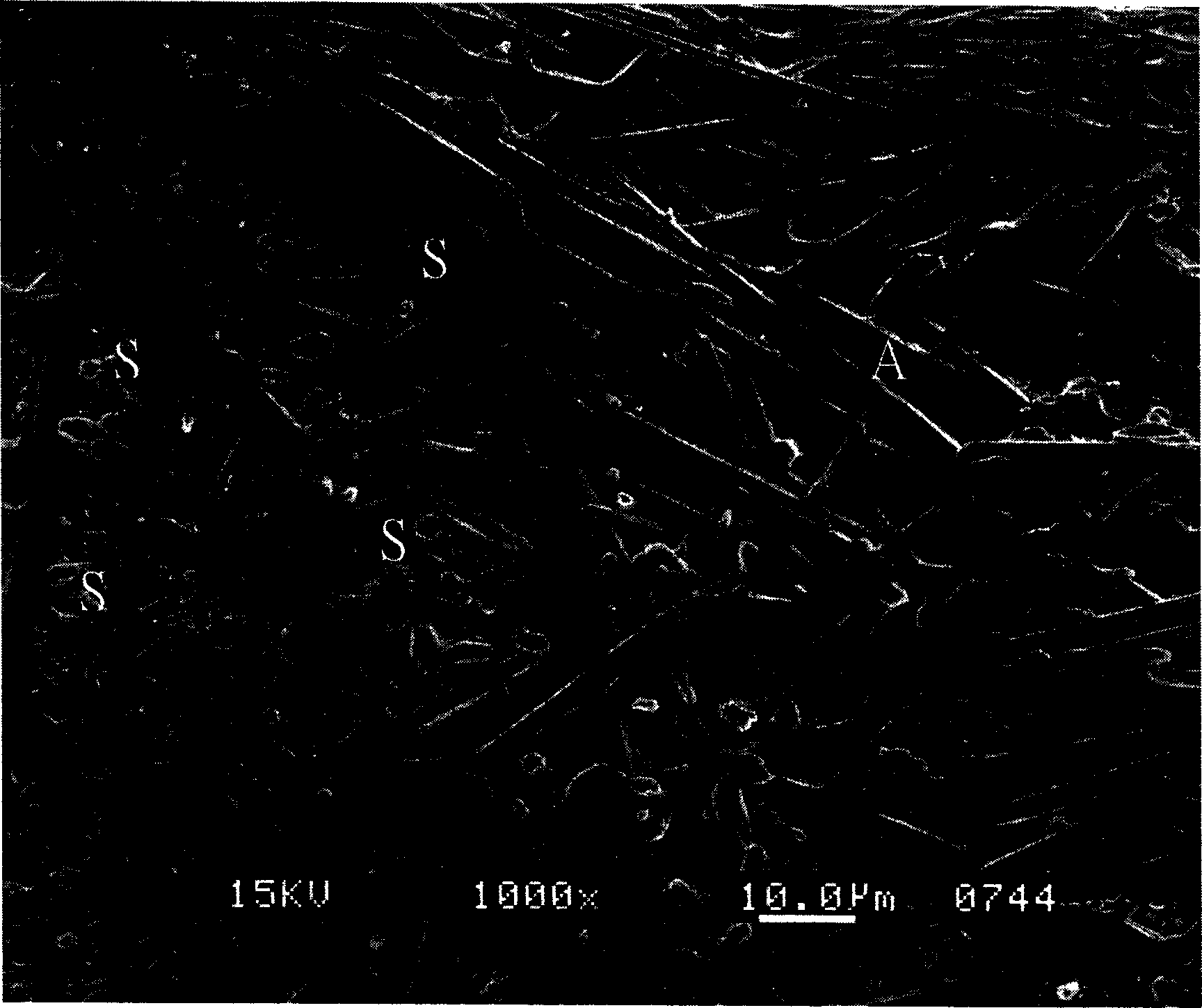

Embodiment 1

[0042] Different weight percentages of calcium fluoride (5% to 35% by weight) and hydroxyapatite (65% to 95% by weight) were placed in deionized water , rolling a ball to mix for twenty-four hours. After mixing, it is taken out and dried, and the dried hydroxyapatite mixture is calcined at a temperature of 700 to 750 degrees Celsius for two hours. The calcined hydroxyapatite mixture was ground into powder by a ball mill and then dried. After the dry powder was filled with polyvinyl acetate and granulated, it was pressed into a disk with a thickness of 0.2 cm and a diameter of 1.3 cm with a pressure of 3 tons per square centimeter. The resulting disk-shaped hydroxyapatite mixture was tested Density test, scanning electron microscope analysis, X-ray diffraction analysis, differential temperature and thermogravimetric analysis were carried out on the slices. After drying, the hydroxyapatite mixture powder without adding polyvinyl acetate was coated with ethanol on the enamel su...

Embodiment 2

[0044] Calcium fluoride acts as a eutectic fusible to make fluoroapatite. Calcium fluoride is the initial reactant that causes the eutectic fusible phenomenon after research, but the calcium hydroxide produced after its reaction with hydroxyapatite is the main eutectic fusible substance. We can also make fluorapatite by mixing 70% by weight of hydroxyapatite with calcium fluoride and calcium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com