Micro-piezoelectric driver for MEMS

A micro-piezoelectric and driver technology, applied in the direction of piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, microstructure devices composed of deformable elements, etc., can solve the driving displacement And problems such as limited deflection, increased driving voltage, and large driver size, etc., to achieve good device driving performance, lower driving voltage, and high device reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

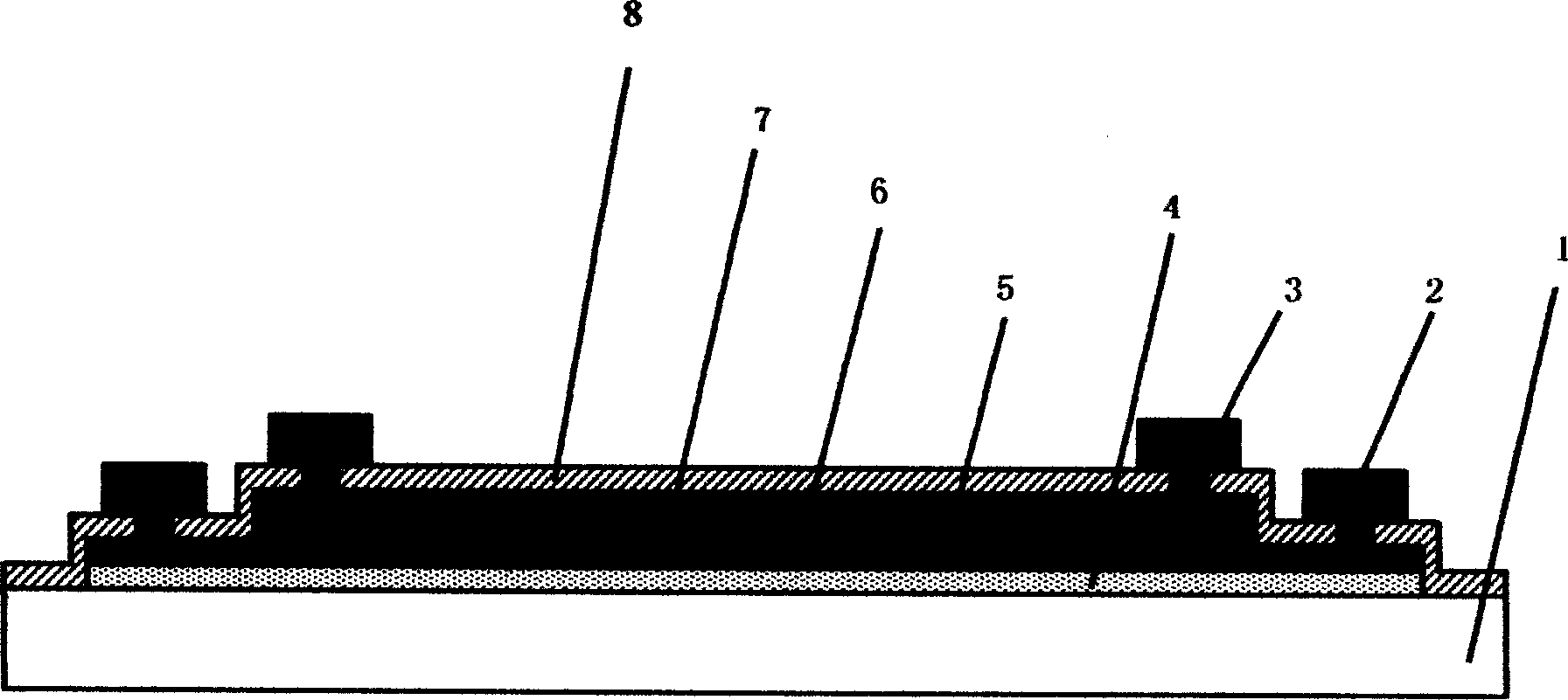

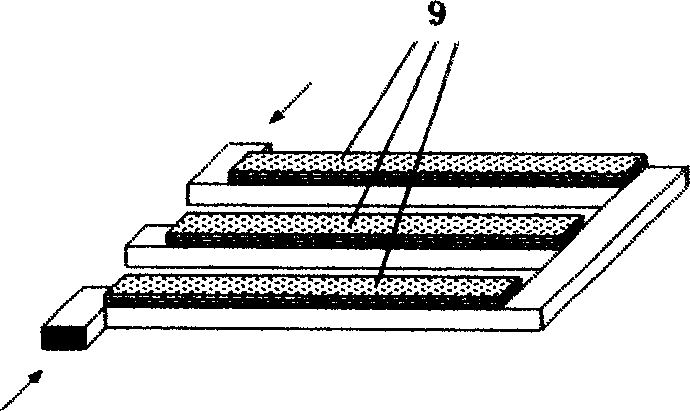

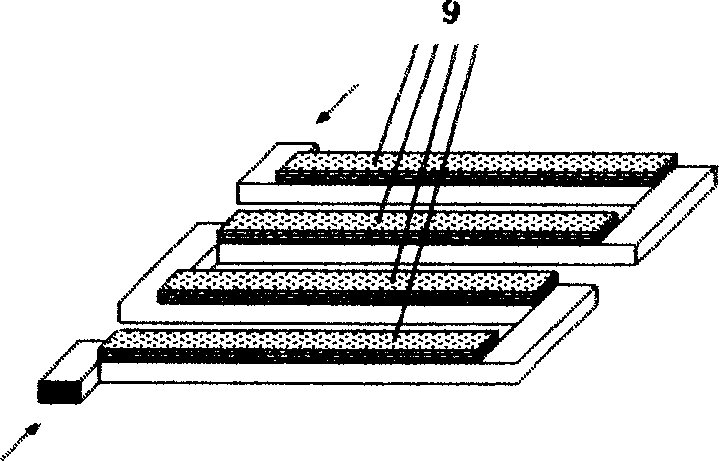

[0016] The invention is a micro piezoelectric driver for MEMS. The micro-piezoelectric driver adopts a folded multi-stage piezoelectric composite multi-layer elastic suspended film structure, that is, a continuous folded parallel arm 9 is formed on the substrate silicon chip 1, and each arm 9 is formed from the elastic silicon substrate layer 1. Covered with a buffer layer 4 from bottom to top, a lower film electrode layer 5 that is not connected to each other, a piezoelectric film 6 with a certain shape, and an upper film electrode layer 7 are compositely stacked, and an insulating dielectric layer 8 can also be covered on the upper electrode film. 7 surfaces; the lower film electrode layer 5 is connected with the lower electrode lead 2, and the upper film electrode layer 7 is connected with the upper electrode lead 3 (as figure 1 shown); on each folded arm, a driving arm using piezoelectric effect is formed, and one or both sides of the driving structure are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com