Ion cross-linked chitosan microballoon, its preparing process and use

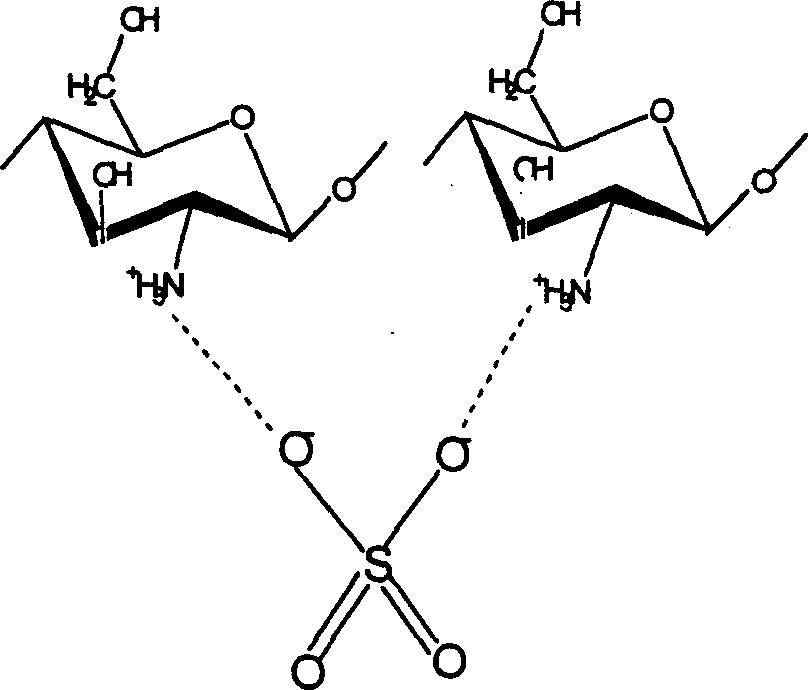

A technology of chitosan microspheres and cross-linked chitosan, applied in sulfuric acid cross-linked chitosan microspheres, chitosan microspheres are used as pharmaceutically acceptable carriers for therapeutic agents, and the field of preparation of microspheres, It can solve the problems of weak ionic cross-linking strength and achieve the effects of avoiding toxicity or other side effects, convenient and economical preparation process, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Get 10ml of chitosan solution of 5% (w / v), join it in the there-necked flask that 80ml liquid paraffin, 2ml Span83 are housed, then add the calcium stearate that dissolves in ether as dispersant, calcium stearate The quality of the solution is 50mg, after stirring for 10 minutes at 20°C and 600 rpm, add 5ml of 50% (W / W) sulfuric acid solution, then add 5ml of sulfuric acid solution at this concentration in 35 minutes, stop stirring after 70 minutes, and turn to 2500 Centrifuge under the condition of 1 / min, wash the solid product alternately and fully with volatile organic solvent and deionized water, and finally dry it under vacuum at 30°C. The particle size of the microspheres is 400-450 μm (>60%).

Embodiment 2

[0046] Get 20ml of chitosan solution of 4% (w / v), join it in the there-necked flask that 100ml sunflower oil, 4ml Span80 are housed, add the sulfuric acid solution of 15% (W / W) after stirring for 10 minutes at 40 ℃ 5ml, add 5ml of sulfuric acid solution of this concentration after 35 minutes, stop stirring after 60 minutes, centrifuge at 3000 rpm, wash the solid product alternately with petroleum ether, acetone and deionized water, and finally dry it under vacuum at 70°C. Can. The particle size of the microspheres is 150-300 μm (>70%).

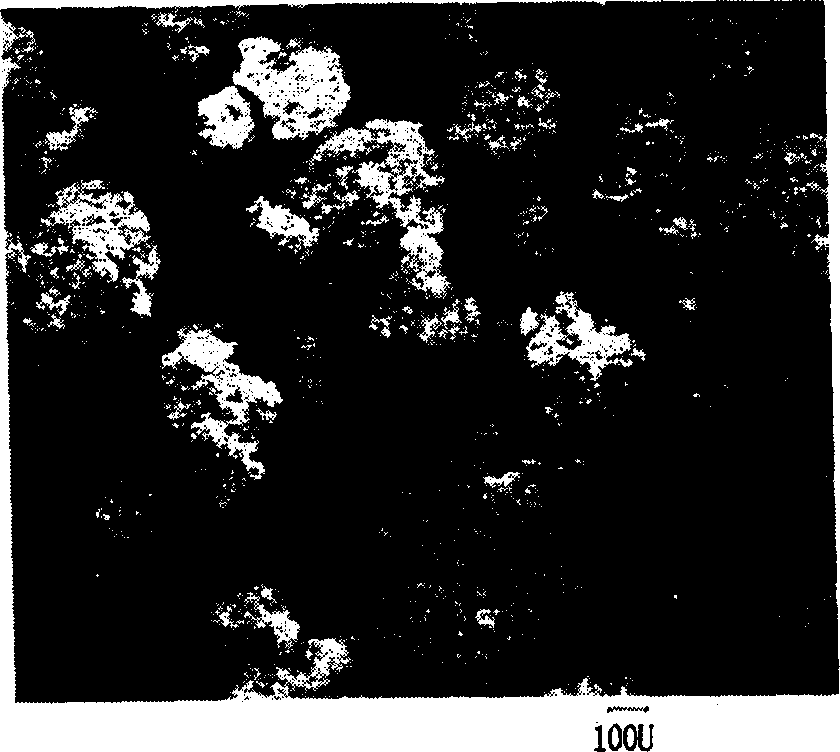

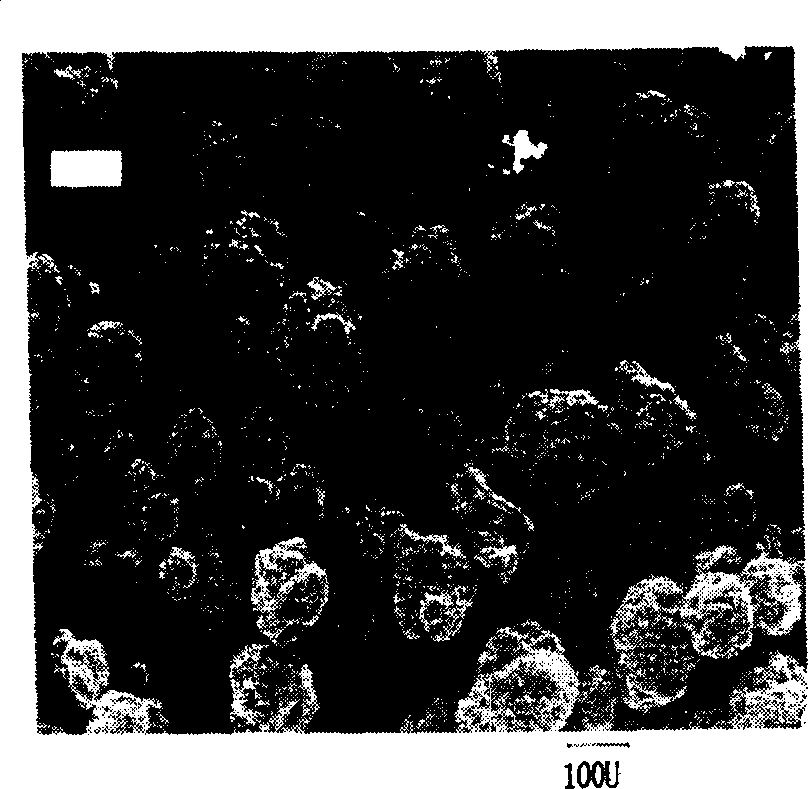

[0047] From image 3 and Figure 4 It can be seen that, compared with the comparative example—the microspheres prepared by using sodium sulfate as cross-linking agent figure 2 Compared (the preparation method is the same as Example 2, the difference is only that the cross-linking agent is different), although the surface of the microspheres prepared in this embodiment is rough, it is denser, and the appearance is also relatively regular. C...

Embodiment 3

[0050] Get 10ml of chitosan solution of 4.5% (w / v), join it in the there-necked flask that 150ml liquid paraffin, 2ml Span80 and 1ml Tween60 (dissolved in 20ml petroleum ether) are housed, then add the stearin soluble in ether Acid is used as a dispersant, and the quality of calcium stearate is 100 mg. After stirring for 10 minutes at 30° C., add 5 ml of sulfuric acid solution of 25% (W / W), add 5 ml of sulfuric acid solution of this concentration in 20 minutes, and stop stirring after 120 minutes. Centrifuge at 4000 rpm, wash the solid product alternately with volatile organic solvents and deionized water, and dry it in vacuum at 40°C. The particle size of the microspheres is 20-40 μm (>80%).

[0051] From Figure 5 and Figure 6 It can be seen that, compared with using sodium sulfate as cross-linking agent ( figure 2 ) and the case of using sulfuric acid as crosslinking agent but without dispersant ( image 3 and Figure 4 ), the surface of the microspheres prepared in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com