Water-based metal antirust protective agent

A protective agent, water-based technology, applied in the direction of anti-corrosion coatings, wax coatings, etc., can solve the problems of easy to stick to dust, smell, inconvenient cleaning of plates, etc., to achieve the effect of easy cleaning and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

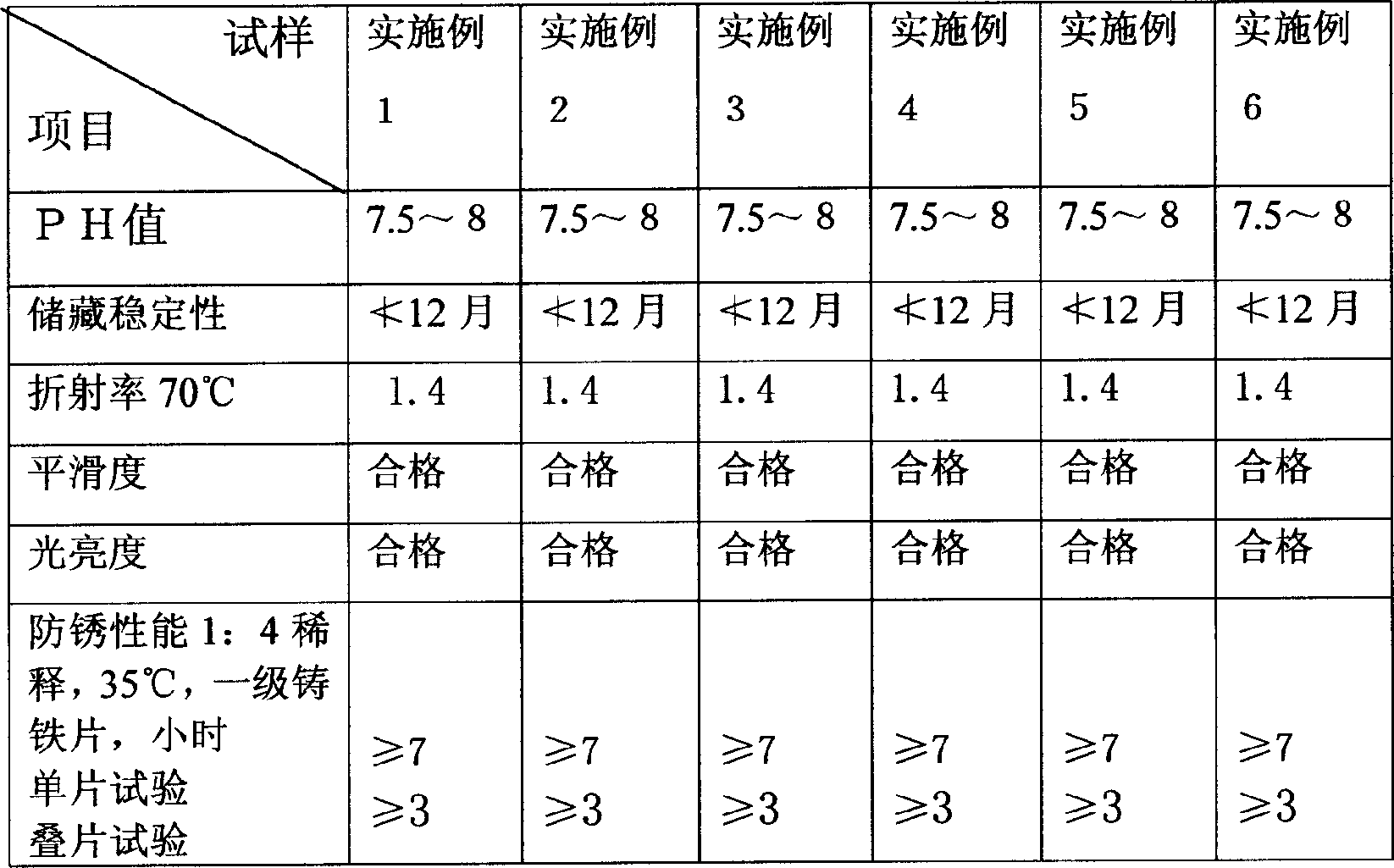

Examples

Embodiment 1

[0029] Get 2% ozokerite oxide, 4% carnauba wax, 6% No. 75 microcrystalline wax, 5% stearic acid, 2% dinonyl naphthalene sulfonate barium, 2% 100 ℃ melting point polyethylene wax, 1.5% molecular weight 6000 polyisobutylene, 5% SE-10 (Tianjin Auxiliary Factory), 1.5% O∏-4 (Tianjin Auxiliary Factory), 1% preservative sodium benzoate.

[0030] Mix wax, polymer, and antirust components at 120°C for 50 minutes to form an oil phase component, add surfactant SE-10, O∏-4, and preservatives to water and heat to 85°C Form the water phase, add the oil phase to the water phase under stirring at a medium speed (about 600 rpm) to mix and pre-emulsify, continue to stir for 15 minutes after the oil phase is added, and after cooling and homogenizing, it will become a metal plate and belt of the present invention. , Water-based anti-rust protective agent products for foil products.

Embodiment 2

[0032] Get 5% carnauba wax, 2% beeswax, 6% castor wax, 6% stearic acid, 3% methyl oleate maleic acid, 3% 100 ℃ melting point polyethylene wax, 2% polystyrene with a molecular weight of 800 Isobutylene, 5% Pingpingjia A-20 (Tianjin Auxiliary Factory), 2% MOA (Tianjin Auxiliary Factory), 1% preservative sodium benzoate.

[0033] Mix wax, polymer, and antirust components at 130°C for 60 minutes to form an oil phase component, add surfactant Pingpingjia A-20, 2% MOA, and preservatives to the remaining water and heat To 90 ℃ into the water phase, stirring at a medium speed (about 600 rpm), add the oil phase to the water phase to mix and pre-emulsify, continue to stir for 20 minutes after the oil phase is added, and after cooling and homogenizing, it is a metal of the present invention. Water-based anti-rust protective agent products for plate, strip and foil products.

Embodiment 3

[0035] Take 4.5% ozokerite oxide, 5% carnauba wax, 4% microcrystalline wax No. 67, 5% dicyclohexylamine stearate, 3% methyl oleate maleic acid, 2% 100°C melting point polyethylene Wax, 7% polyisobutylene with a molecular weight of 600, 6% Pingpingjia C-125 (Tianjin Auxiliary Factory), 2% MOA (Tianjin Auxiliary Factory), 1% preservative sodium benzoate.

[0036] Mix wax, polymer, and antirust components at 130°C for 60 minutes to form an oil phase component, add surfactant Pingpingjia C-125, MOA, and preservatives to water and heat to 90°C to form an oil phase component. For the water phase, add the oil phase to the water phase for mixing and pre-emulsification under medium-speed (about 600 rpm) stirring. After the oil phase is added, continue to stir and stabilize for 20 minutes. After cooling and homogenizing, it is a metal plate, strip, Water-based antirust protectant product for foil products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com