Liquid crystal high molecular material and its preparing method

A liquid crystal polymer, mole fraction technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of difficult control of the end point of polymerization reaction, narrow processing temperature range, high polymerization temperature, etc., and achieve wide processing temperature range and easy preparation , the effect of low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-19

[0017] LCP preparation

[0018] The polycondensation reaction is carried out in a stainless steel reactor. The reactor is heated by electric heating, and the temperature is accurately controlled by the control unit. After the agitator is decelerated by the gear reducer, it is controlled by the speed controller. During the reaction, the speed and torque can be read continuously from the speed controller. Torque indicates melt viscosity, that is, the size of molecular weight. The reaction kettle is connected with a toothed separator, a water condenser, and a collector. N 2 The gas is connected to the reactor through the needle valve, N 2 Air flow is controlled by a needle valve. The vacuum system is connected to the reactor through a needle valve, and the speed of vacuuming is controlled by the needle valve. In pass N 2 Under the condition of gas, put the reactant into the reactor, and add a certain amount of catalyst. Turn on the stirrer at a speed of 150 rpm. The tem...

Embodiment

[0024] Example HBA HQ MA DODA TA M+D / T (mA) (°C) (°C)

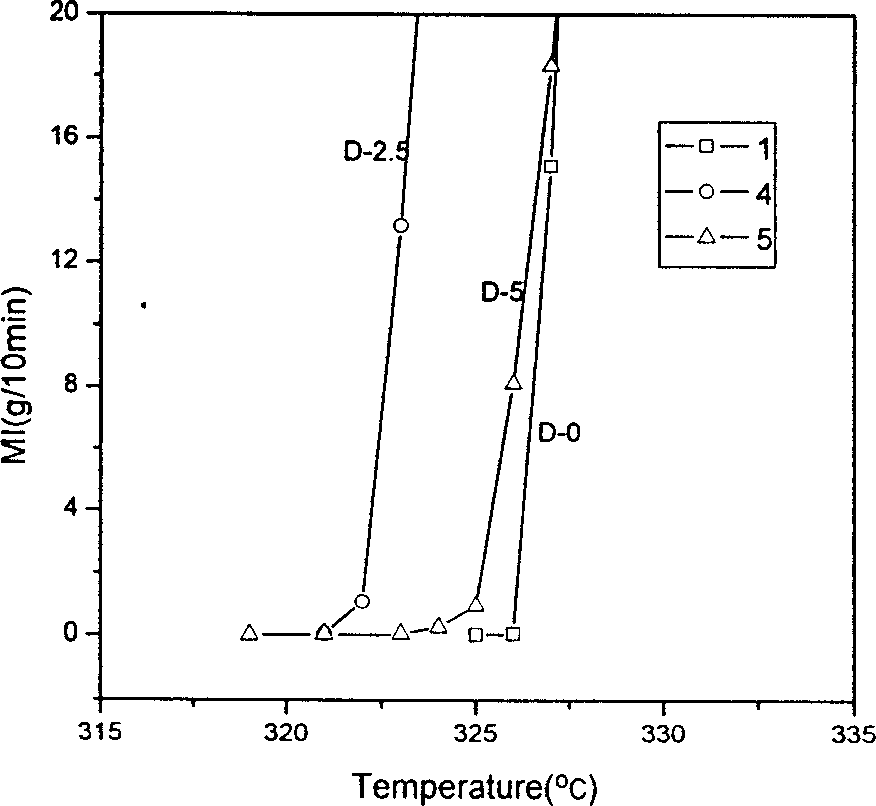

[0025] 1 54 23 15 0 8 65 / 35 0.61 321.2 325-328

[0026] 2 54 23 13.8 0 9.2 60 / 40 0.59 329.5 329-333

[0027] 3 54 23 12.4 0 10.6 54 / 46 0.61 336.4(2) 340-345

[0028] 4 54 23 12.5 2.5 8 65 / 35 0.60 315.8 321-325

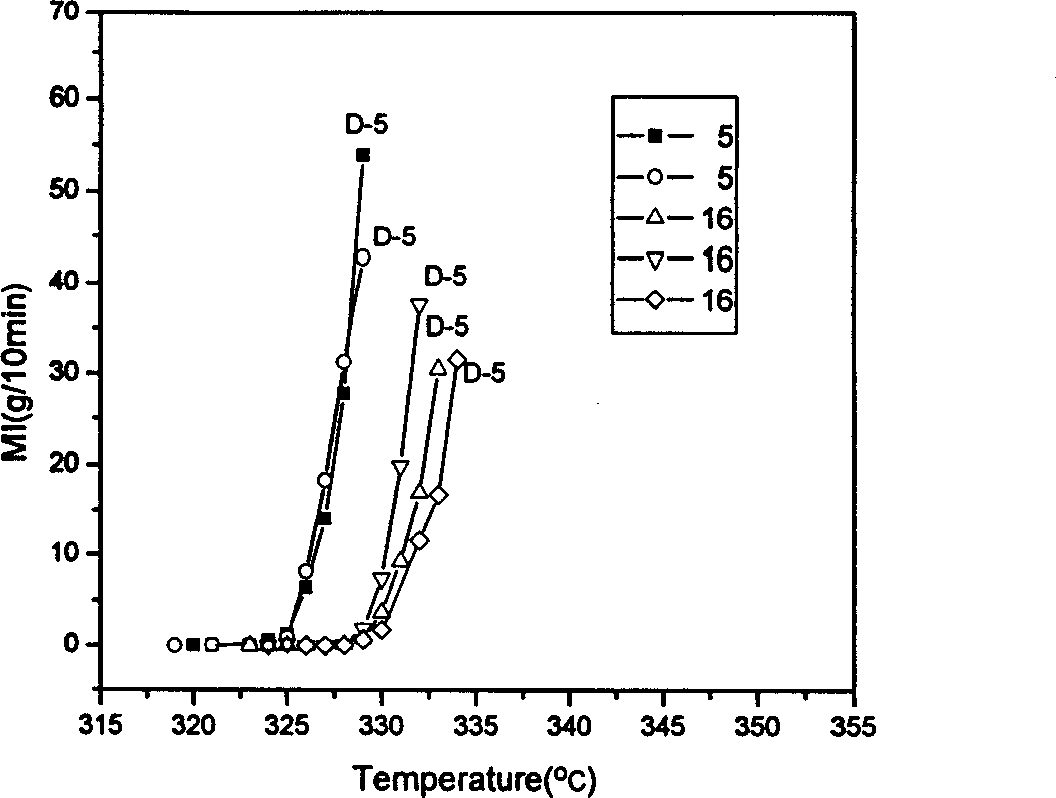

[0029] 5 54 23 10 5 8 65 / 35 0.61 319.4(2) 319-329

[0030] 6 54 23 7.5 7.5 8 65 / 35 0.66 334.6(2) 334-339

[0031] 7 54 23 11.3 2.5 9.2 60 / 40 0.62 326.5 328-338

[0032] 8 54 23 8.8 5 9.2 60 / 40 0.61 331.3(2) 333-341

[0033] 9 57 21.5 12.9 0 8.6 60 / 40 0.62 332.6 337-342

[0034] 10 57 21.5 12.0 3 6.5 70 / 30 0.62 313.9 316-321

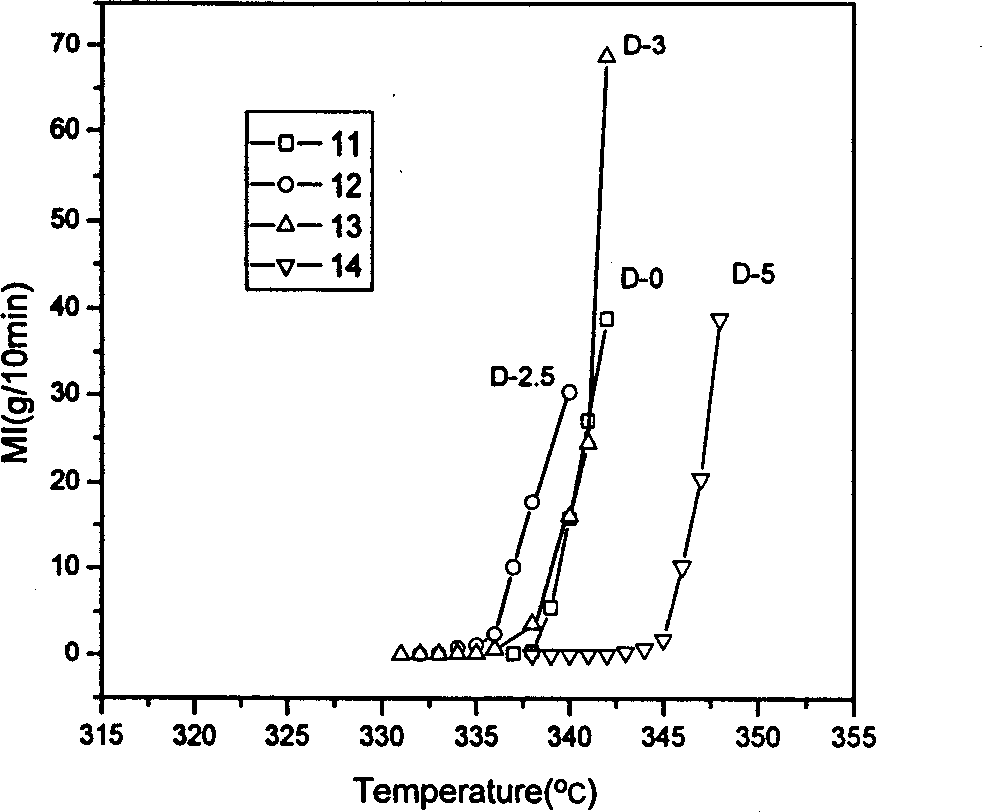

[0035]11 57 21.5 10.0 5 6.5 70 / 30 0.62 314.3(2) 318-326

[0036] 12 57 21.5 10.4 2.5 8.6 60 / 40 0.66 328.6(2) 332-340

[0037] 13 57 21.5 9.9 3 8.6 60 / 40 0.61 326(2) 331-342

[0038] 14 57 21.5 7.9 5 8.6 60 / 40 0.62 339.1(2) 338-348

[0039] 15 60 20 12 0 8 60 / 40 0.63 331.2(2) 338-344

[0040] 16 60 20 9 5 6 70 / 30 0.63 324.8 324-332

[0041] 17 60 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com