Phase change composite spinning solution and its preparation and application

A technology of composite spinning and phase change, which is applied in the field of phase change composite spinning stock solution and its preparation and application, to achieve the effects of excellent barrier property, strong adsorption force, high specific surface area and surface area to volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of phase change composite spinning dope:

[0030] The phase change material is PEG with different molecular weights, and the solvent is DMSO, acetone or acetic acid; the fiber-forming polymer material is cellulose and its derivatives, including microcrystalline cellulose, wood pulp, cellulose diacetate, triacetic acid Cellulose, the solvent is DMSO, acetone or acetic acid; the weight ratio of phase change substance and fiber-forming high polymer is 30-50:70-50, and the concentration of spinning dope is 10-15wt%.

[0031] Application of phase change composite spinning solution:

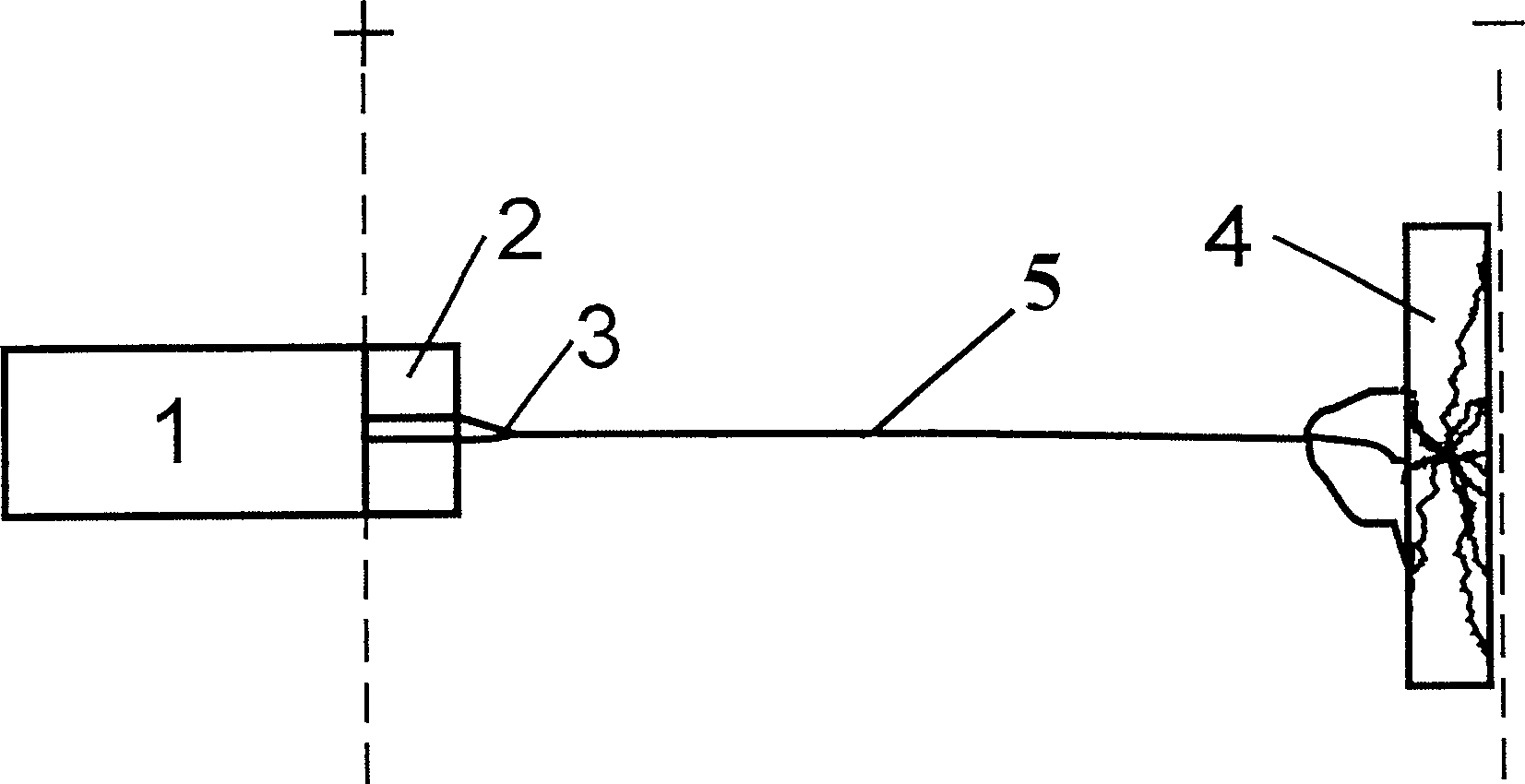

[0032] The heat preservation temperature of the pump body of the metering pump 1 is 20-45°C; the capillary aperture of the spinneret die 2 is 0.2-0.3mm, the air at 20-50°C is used as the medium in the spinning process, and the air velocity is 0-1m / min, The electrostatic field voltage is 10~60kv; the average diameter of the prepared fibers is 20~200nm, the phase transition temperatur...

Embodiment 2

[0034] Preparation of phase change composite spinning dope:

[0035] The phase-change substance is PEG with different molecular weights, and the solvent is acetic acid; the fiber-forming high polymer material is chitin, and the solvent is acetic acid; the weight ratio of the phase-change substance and the fiber-forming polymer is 20-50:80-50, The concentration of the spinning dope is 2-10 wt%.

[0036] Application of phase change composite spinning solution:

[0037] The heat preservation temperature of the pump body of the metering pump 1 is 20-45°C; the capillary aperture of the spinneret die 2 is 0.2-0.3mm, the air at 20-50°C is used as the medium in the spinning process, and the air velocity is 0-1m / min, The electrostatic field voltage is 10~60kv; the average diameter of the prepared fibers is 20~200nm, the phase transition temperature of the fibers and the fiber mat is 40~45℃ when heating up, the phase transition temperature is 26~22℃ when cooling down, and the phase tra...

Embodiment 3

[0039] Preparation of phase change composite spinning dope:

[0040] The phase change material is PMA or PA, the solvent is a mixture of DMF and acetone, and the blending weight ratio of DMF and acetone is 2:98 to 98:2; the fiber-forming high polymer material is polyacrylonitrile, and the solvent is a mixture of DMF and acetone. In the mixture, the blending weight ratio of DMF and acetone is 2:98-98:2; the weight ratio of phase change substance and fiber-forming high polymer is 50-70:50-30, and the concentration of spinning dope is 8-15wt%.

[0041] Application of phase change composite spinning solution:

[0042] The heat preservation temperature of the pump body of the metering pump 1 is 50-90°C; the capillary aperture of the spinneret die 2 is 0.3-0.8mm, the air at 50-100°C is used as the medium in the spinning process, and the air velocity is 0-1m / min, The electrostatic field voltage is 10-60kv; the average diameter of the prepared fibers is 100-600nm, the phase transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com