Method for preparing precursory wire made from composite material of Ti alloy base enhanced by continuous SiC fibre

A composite material and fiber-reinforced technology, which is applied in the field of continuous SiC fiber-reinforced Ti alloy-based composite precursor wire preparation, can solve problems such as fiber surface damage, poor coating thickness uniformity, and fiber performance degradation, and achieve no damage to the fiber surface , the interface is well bonded, and the effect of fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

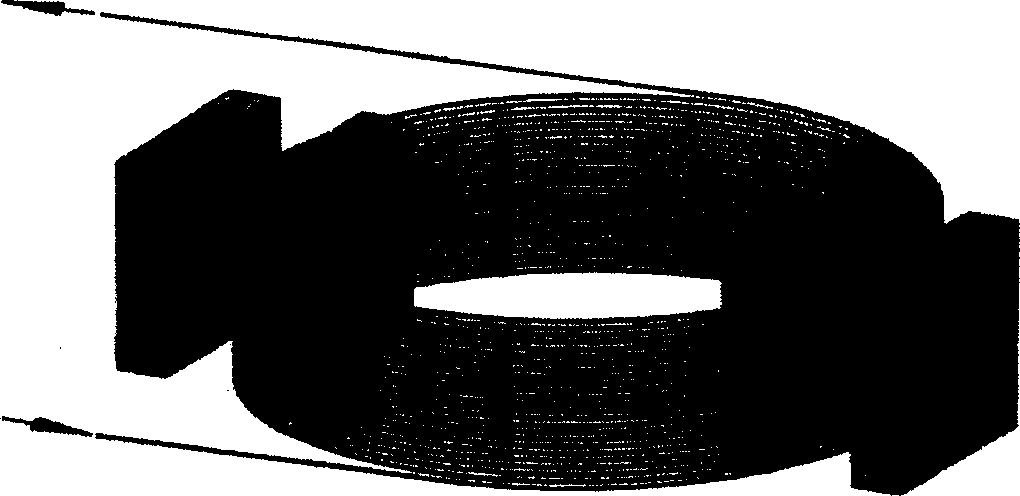

[0023] 1) With the continuous SiC fiber as the matrix, the surface of the matrix is decontaminated by conventional methods such as alcohol or acrylic copper, and then the matrix is wound on the sample holder with the Ti alloy as the target material, such as figure 1 shown;

[0024] 2) Put the matrix wound on the sample holder with Ti alloy as the target into the vacuum chamber, first pre-evacuate, and set heaters (same as the target placement method) on both sides of the matrix as auxiliary means, at 500 ° C Bake the vacuum chamber at ~600°C (550°C in this embodiment), and at the same time heat the substrate evenly while the substrate is rotating, so that the working pre-vacuum degree meets the requirements; then pass in argon gas through the control of the valve; then, start The stepper motor rotates the base body to preheat the base body; the power supply of the double-pair target magnetron sputtering instrument is started again, and the base body after the preheating is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com