Glicetin -1 slow release microspheric preparation and its use

A technology of slow-release microsphere preparations and glucagon, which is applied in the field of medicine and can solve the problems of restricting the development and utilization of drugs and short half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Embodiment 1: GLP-1 sustained-release microsphere preparation prepared by w / o / w solvent volatilization method

[0034] Dissolve 100 mg of PLGA (RG502H, PLA:PGA=50:50, Mw=34000) in 1.0 ml of dichloromethane to make an oil phase; dissolve 3 mg of GLP-1 (SIGMA company, the same below) in 0.1 ml of double distilled water (Containing 3% trehalose, 5% mannitol) to form the inner water phase, add it to the above oil phase, ultrasonic emulsification, form w / o colostrum, 30ml of 3% PVA solution (containing NaCl 2% and F- 68 0.5%) in a stirring container, quickly add the colostrum into the external water phase under stirring at 1000rpm to fully homogenize, after three minutes, lower the rotation speed to 400rpm and add 30ml of distilled water to the external water phase, stir at room temperature for 4 hours, After hardening, the microspheres were centrifuged, washed, and freeze-dried. Subpackaged and sealed, then irradiated and sterilized. The encapsulation efficiency of GLP-1 m...

Embodiment 2

[0035] Embodiment 2: s / o / o solvent volatilization method prepares GLP-1 sustained-release microsphere preparation

[0036] Disperse 24 mg of PEG (PEG6000), 3 mg of GLP-1 and 5 mg of protective agent zinc carbonate in 1 ml of double-distilled water, vortex and mix for about 3 minutes, freeze-dry, wash with dichloromethane, and centrifuge to remove PEG to obtain GLP-1 Micronized. PLGA (RG502H, PLA:PGA=50:50, M w =34000) 200 mg was dissolved in 1.0 ml of acetonitrile to make an oil phase, the above micropowder was added into the oil phase, ultrasonically dispersed, it was added dropwise into cottonseed oil to fully homogenize, stirred at 600 rpm for 1 hour, and then an appropriate amount of petroleum ether was added to Continue to stir at 400rpm for 2 hours to obtain GLP-1 microspheres, centrifuge, wash with petroleum ether, collect, freeze-dry, subpackage and seal, and then irradiate and sterilize. The encapsulation efficiency of the GLP-1 microspheres is 90%, and the particle...

Embodiment 3

[0037] Embodiment 3: Preparation of GLP-1 sustained release microsphere preparation by spray drying method

[0038] Dissolve 8 mg of GLP-1 and 30 mg of protective agent human serum albumin in 10 ml of double distilled water, spray into liquid nitrogen, and volatilize the liquid nitrogen at low temperature to obtain GLP-1 micropowder. PLGA (RG502H, PLA:PGA=50:50, M w =34000) 600 mg was dissolved in 10 ml of dichloromethane to make an oil phase, the micropowder was added into the oil phase for ultrasonic dispersion, and spray-dried, the inlet temperature was 40°C, the outlet temperature was 30°C, the spray pressure was 5Pa, the nozzle diameter was 0.5mm, and the flow rate was 1 ~2ml / min. The collected microspheres were vacuum-dried at room temperature for 6 hours, subpackaged and sealed, and then sterilized by irradiation. The encapsulation efficiency of GLP-1 microspheres is 80%, and the particle size is less than 60 μm.

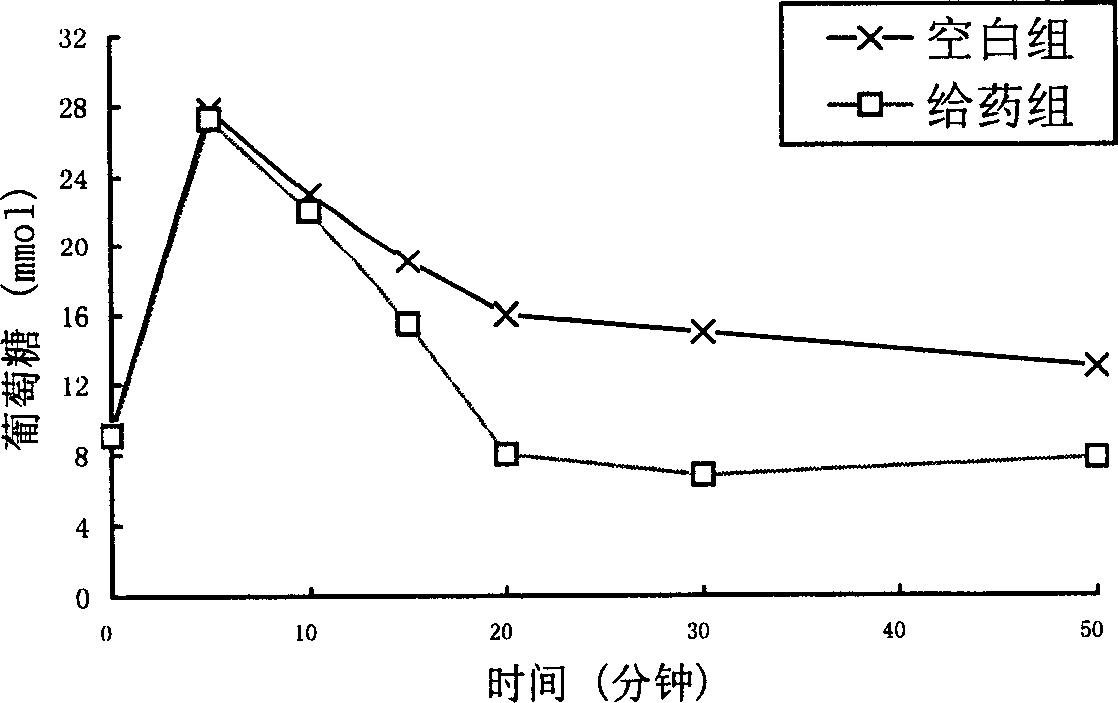

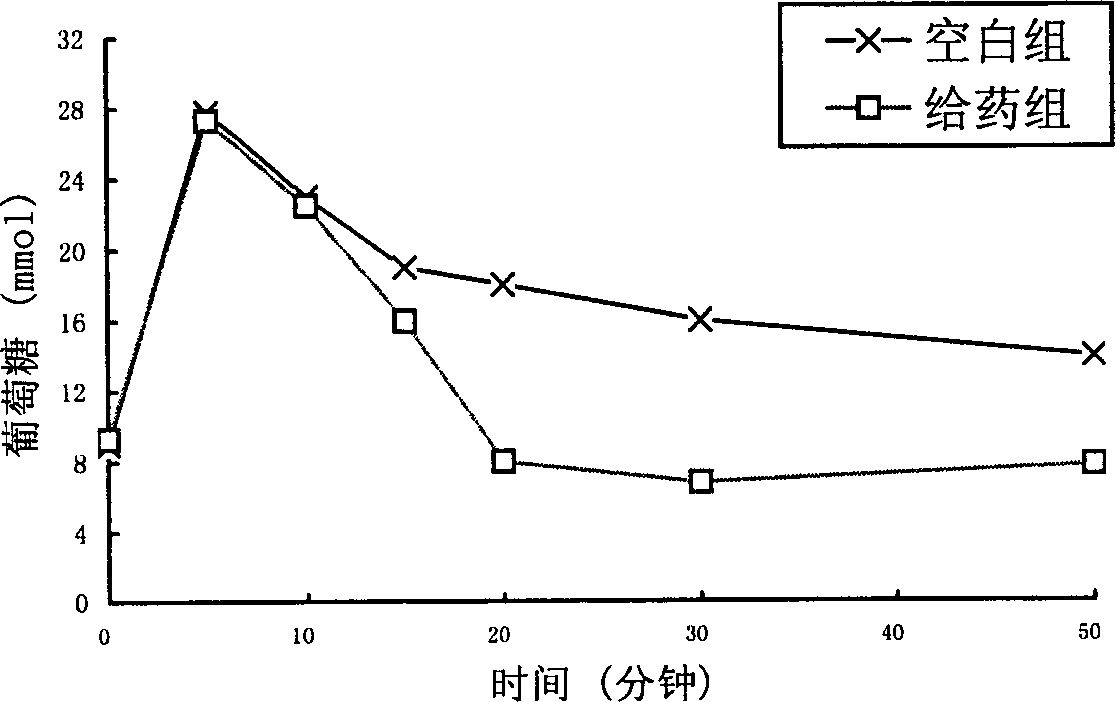

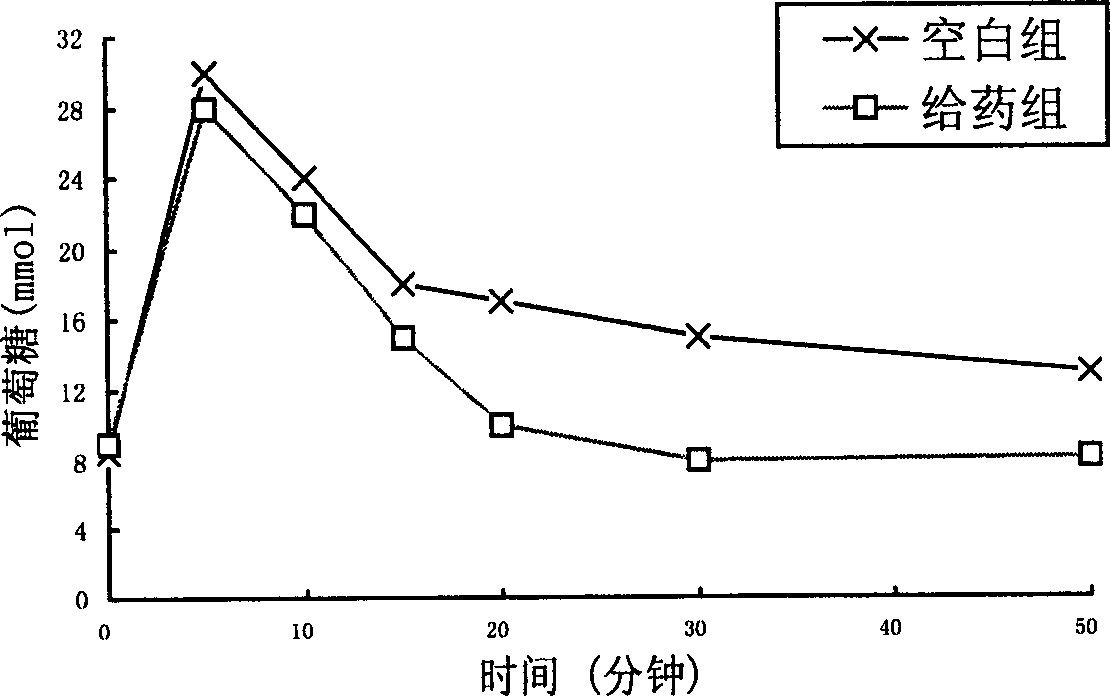

[0039] Animal experiment: choose 16 adult wister rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com